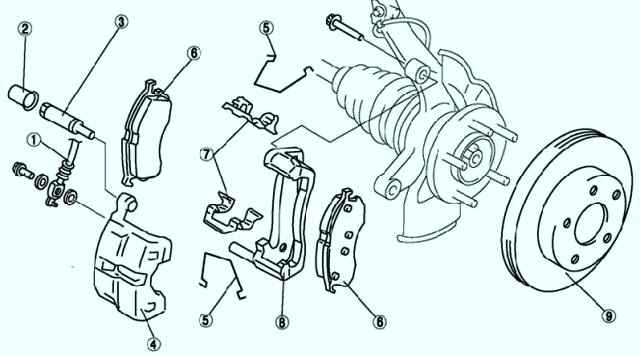

Checking the brake disc

Check for corrosion, wear and damage on the inner walls of the cylinder.

Replace cylinder body if necessary

Minor flaws caused by corrosion or foreign particles can be removed by sanding the surface with fine emery cloth.

Check for corrosion, wear and damage on the piston surface, guide pin, guide pin boot and brake disc surface.

If necessary, replace the corresponding component.

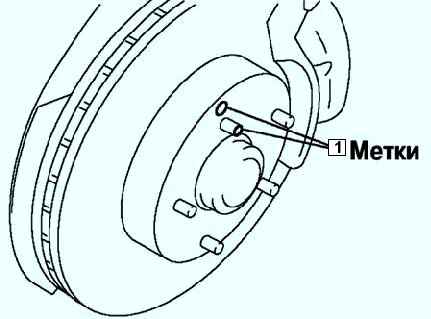

Mark the wheel hub bolt and the brake disc before removing for later installation (Fig. 2.).

Unscrew the mounting bolt and remove the brake hose.

Remove the guide pin cover and the pin itself.

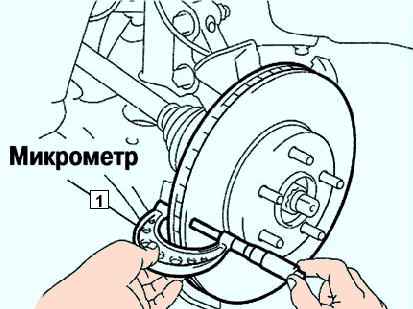

Using a micrometer, measure the thickness of the brake disc (fig. 3).

Standard thickness: 26 mm. Minimum thickness: 24 mm.

Replace the disc if the disc is less than the minimum thickness.

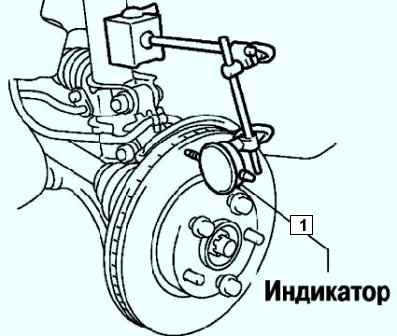

Attach the brake disc to the wheel hub with wheel nuts (two or more locations).

Check the runout with an indicator (fig. 4). Measuring point: – 10 mm from the outer edge of the disc. Maximum runout: 0.05mm or less

Make sure the end play is 0 mm before measuring.

If the runout is significant, find the point of minimum runout by sequentially shifting the installation position of the brake disc on the hub by one hole.

Remove rust or dirt from the contact surface of the brake disc and wheel hub.

Install the brake disc and align the marks made before removal.

More details, front brake discs replacement

Brake discs are replaced by a pair, in both front wheel brakes at once

When replacing brake discs, brake pads must be replaced

We unscrew the two bolts with a 17 key securing the guide pads to the steering knuckle

Remove the caliper assembly from the guide pad without disconnecting the brake hose from the caliper

We tie the caliper to the front suspension strut

For insurance, we wind the wheel nut onto the stud

Remove the brake disc by tapping it with a hammer through a wooden spacer

We clean the disc seat on the hub from dirt and rust

After checking or replacing, install the parts in reverse order