Remove the starter for repair or replacement

The starter is mounted on the clutch housing at the rear of the power unit

Disconnect the negative battery terminal

Remove the air filter

Remove the protective cap of the power cable tip

Disconnect the control wire block from terminal "50" of the starter traction relay

Unscrew the fastening nut and remove the power wire from the contact bolt of the traction relay

We unscrew the two starter mounting bolts and remove the starter from the car

Starter repair

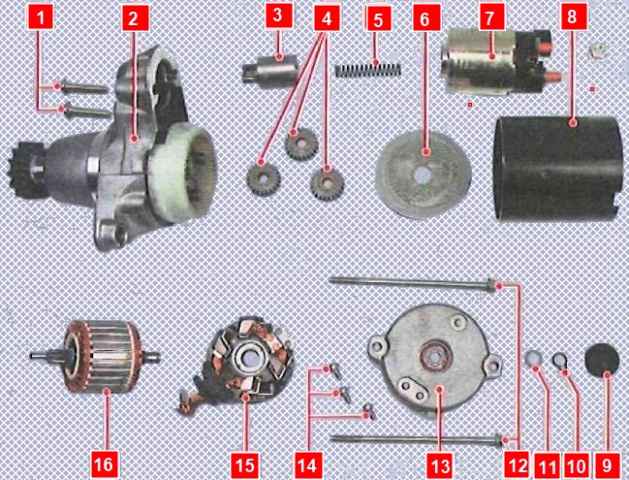

The figure shows the details of the starter

Before disassembling the starter, you need to make sure that it is defective by simple checks:

Turn the drive gear.

The gear should rotate easily relative to the clutch hub in the direction of rotation of the rotor and should not rotate in the opposite direction

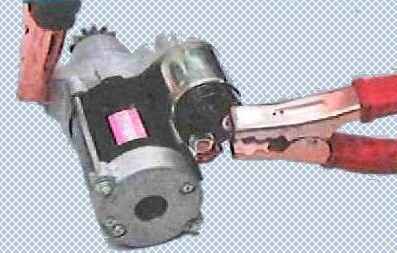

After that, we connect the minus terminal of the battery removed from the car with the starter housing with wires.

We connect the second wire with one end to the positive terminal of the battery, and with the other to the upper contact bolt of the traction relay

We connect the plus terminal of the battery with the output of the control drive of the traction relay.

If the traction relay is working properly, then a click is heard and the drive clutch will extend.

After that, the starter rotor should begin to rotate at a frequency of more than 6000 min -1. Otherwise, we repair the starter

Unscrew the nut of the lower contact bolt of the traction relay and disconnect the bus from the contact bolt

We unscrew the two screws securing the traction relay to the starter cover from the drive side and remove the traction relay

Remove the return spring from the traction relay case

Disconnect from the drive lever and remove the anchor of the traction relay

We unscrew the two coupling bolts and remove the starter drive assembly

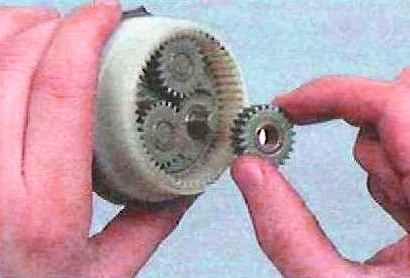

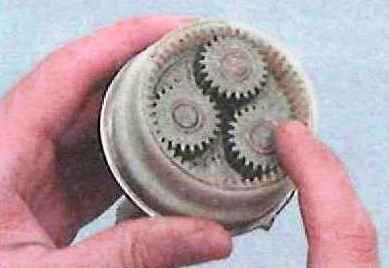

Remove three planetary gearbox gears from the drive axles

It is better not to disassemble the starter drive. To assemble it, you need special equipment

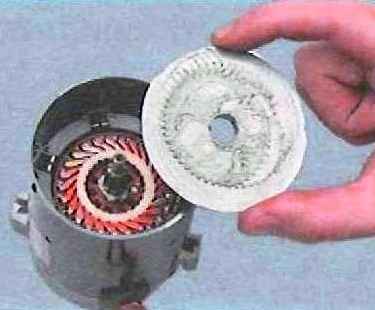

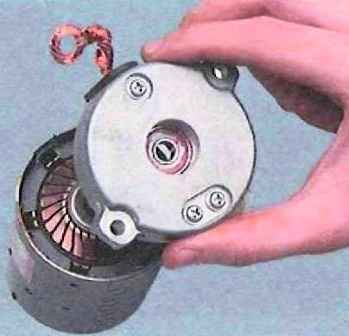

Remove the planetary gear cover from the starter housing

Use a screwdriver to pry off and remove the rubber plug from the cover on the side of the collector

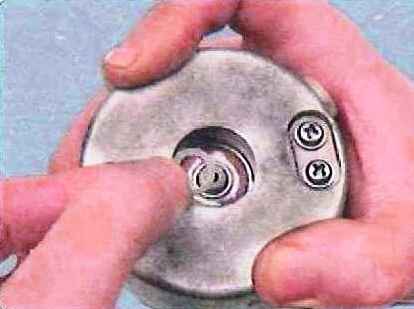

Remove the retaining ring, flat washer

And we separate the body and cover from the manifold side

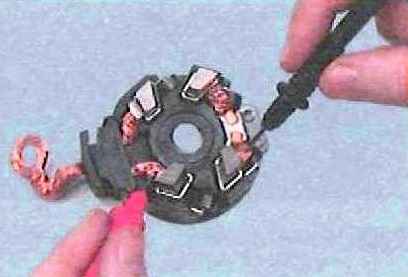

Remove and inspect the brush holder.

Checking the height and condition of the brushes.

If the brushes protrude less than 4 mm, are oily or stick when moving, replace the brush holder

Using an ohmmeter, we check the resistance between the positive and negative brushes. Resistance should tend to infinity

Remove the rotor from the starter housing

The splines and trunnions of the rotor shaft must not be damaged (nicks and burrs).

The collector must not have a trail ov burning.

Minor burns are removed with a rag soaked in gasoline and fine-grained sandpaper

Using an ohmmeter, we check the rotor winding for a short circuit. Resistance should tend to infinity

Check whether the armature of the starter traction relay moves easily, whether the contact bolts are closed with a contact plate (using an ohmmeter)

Checking the drive. The teeth of the drive gear should not have significant wear.

The gear should rotate easily relative to the clutch hub in the direction of rotation of the rotor and should not rotate in the opposite direction.

If the gear teeth are worn or damaged, or the gear rotates in both directions, replace the drive

We assemble the starter in the reverse order, taking into account the following features

Lubricate the gears of the planetary gear with grease

Before installing the traction relay, apply a thin layer of silicone sealant to the surface of the relay in contact with the starter cover on the drive side