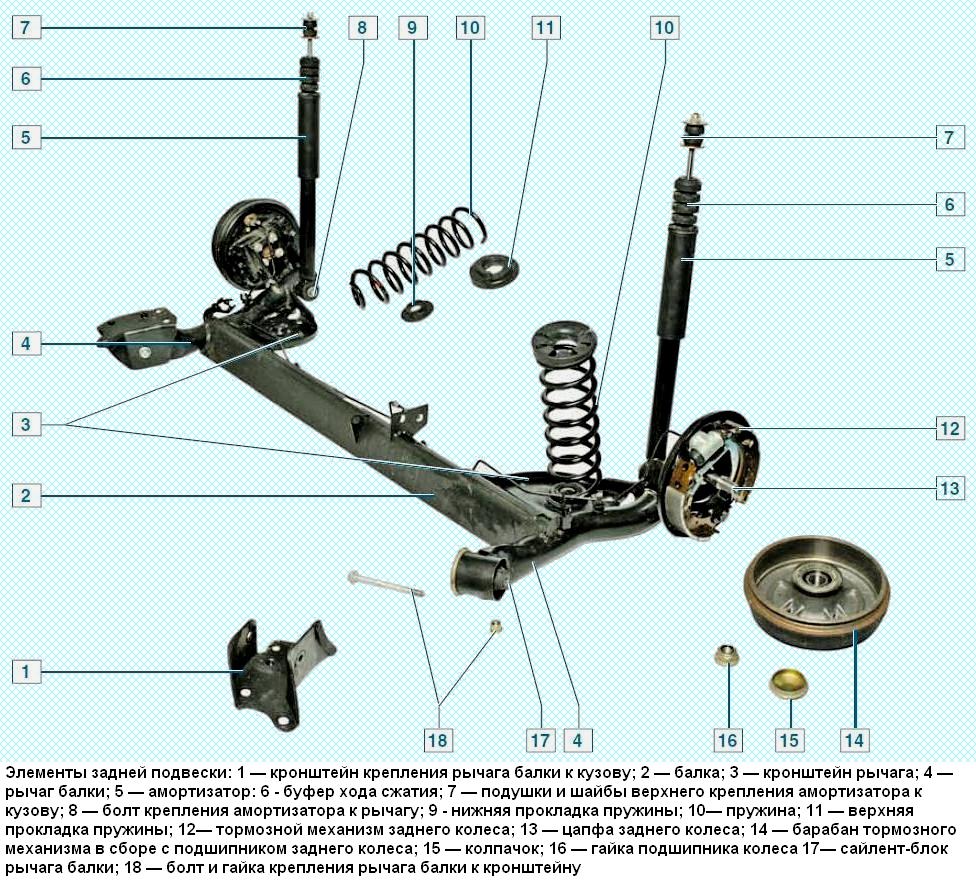

The rear suspension is semi-independent, lever-spring with trailing arms hinged to the car body and interconnected by a U-shaped transverse beam

The trailing arms are connected to the body with silent blocks.

Suspension springs are cylindrical.

The upper and lower ends of the springs are supported by elastic rubber pads.

A torsion-type anti-roll bar can be installed in the suspension beam.

The lower ends of double-acting telescopic hydraulic shock absorbers are bolted to the suspension arms (Fig. 1).

The upper ends of the shock absorbers are attached to the body through rubber pads.

Rear suspension springs are divided into classes according to stiffness. Spring class is marked with paint.

Springs of the same class must be installed on the right and left sides of the car.

When replacing, it is recommended to install springs of the same class that were installed on the car.

A rubber-metal hinge is pressed into the lower eye of the shock absorber, through the central bushing of which a bolt passes, securing the shock absorber to the suspension arm.

The shock absorber rod is attached to the body through two rubber pads (one at the bottom of the support, the other at the top) and two metal washers.

A spacer sleeve is installed between the cushions on the damper rod, which prevents the cushions from being excessively deformed when the stem nut is tightened.

The shock absorber is fitted with a compression stroke buffer to which the boot is attached.

Each rear wheel hub is mounted on two tapered roller bearings.

The installation angles of the rear wheels are specified by the beam geometry and cannot be adjusted in operation.

Angles can only be checked on a special stand and compared with control values.

If the values of the rear wheel alignment angles do not correspond to the control values, it is necessary to check the condition of the rear suspension elements.

Possible malfunctions of the rear suspension and solutions

Cause of malfunction Remedy

Noise and knock in the suspension when the car is moving

Shock absorber defective - Replace shock absorber

Loose shock absorber mounting or worn shock absorber lug bushing - Tighten the shock absorber lower mounting bolt and nut or replace the bushings

Worn trailing arm bushings - Replace bushings

Settlement or broken spring - Replace spring

Faulty wheel bearing - Replace bearing

Moving the car away from straight ahead

Inflated tire pressure - Set correct tire pressure

Wheel tires have different wear or tread pattern - Change tires

Camber out of alignment - Eliminate cause of camber out of alignment

Settlement or breakage of one of the springs - Replace the spring

Deformation of trailing arms - Replace silent blocks

Increased or excessive tire tread wear

Tire pressure not correct - Set correct pressure

Wheels misaligned - Remedy for misaligned wheels

Overloading the vehicle - Avoid overloading the vehicle

Wheel imbalance - Balance the wheels