On cars, in some trim levels, it is possible to install an electromechanical power steering

The main differences between such an amplifier and a hydraulic one are: part of the engine power is not taken to drive the pump; it is possible to differentiate the force on the steering wheel depending on the speed of the vehicle (feedback).

The electromechanical power steering is mounted on the steering column and acts directly on the steering shaft.

To work together with an electromechanical amplifier, a steering mechanism is installed on the car, similar in design to the mechanism of the VAZ-2123 Niva car, but with a number of improvements that increase its reliability and accuracy.

Removing and installing the steering column

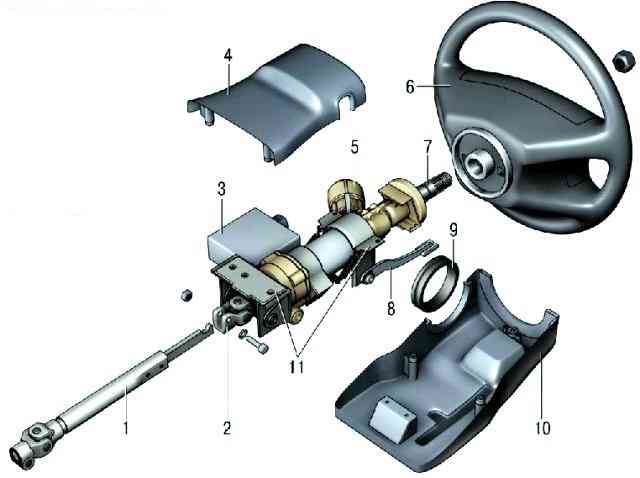

The elements of the steering column with an electromechanical amplifier are shown in fig. 1.

In the engine compartment, unscrew the nut of the coupling bolt securing the lower end of the intermediate shaft 1 (Fig. 1) to the shaft of the steering gear worm and remove the coupling bolt.

In the passenger compartment, unscrew the screws securing the steering column shaft seal and remove it.

Remove steering column covers 4 and 10.

Disconnect the wire blocks from the steering column switches, ignition switch and electromechanical amplifier.

Unscrew the bolts and nuts securing the steering column and remove it complete with shafts 1, 7 and steering wheel 6.

If necessary, remove the electromechanical power steering from the steering column and check its operation according to the separate power steering manual supplied with the vehicle.

Install the steering column in the reverse order of removal.

Removing and installing the steering gear

The steering gear is removed for replacement or repair. Disassembly and assembly of the mechanism require the use of a special tool and the skills of the performer.

If these conditions are not met, we recommend having the steering gear repaired in a specialized workshop.

Mount the car on a lift or a viewing hole.

Disconnect the wire from the "-" terminal of the battery.

Unscrew the nut of the pinch bolt securing the lower end of the intermediate shaft 1 (see Fig. 1) to the steering worm shaft and remove the pinch bolt.

Remove the cotter pins of the nuts securing the ball joint pins to the bipod and unscrew the nuts.

Using a puller, press the ball studs out of the bipod holes.

Unscrew the nuts of the bolts securing the steering gear to the body side member and remove the steering gear.

Install the steering gear in the reverse order of removal, doing the following:

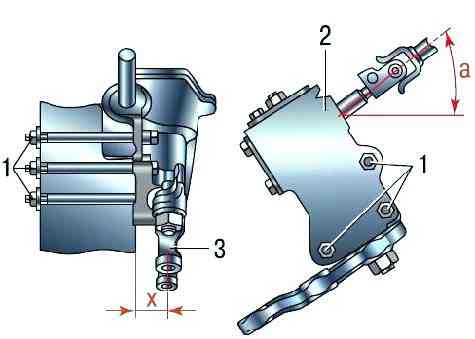

- - set the steering mechanism bipod to the middle position, while the mark on the end of the worm shaft should be located horizontally to the right (in the direction of the vehicle) and the distance "x" (Fig. 2) from the center of the lower hole of the bipod to the supporting surface on the side member body should be (33.1+5) mm;

- – before tightening the nuts of bolts 1, orient the steering mechanism so that the angle a is 32°;

- - check and, if necessary, adjust the angles of the front wheels.

Disassembly and assembly of the steering mechanism

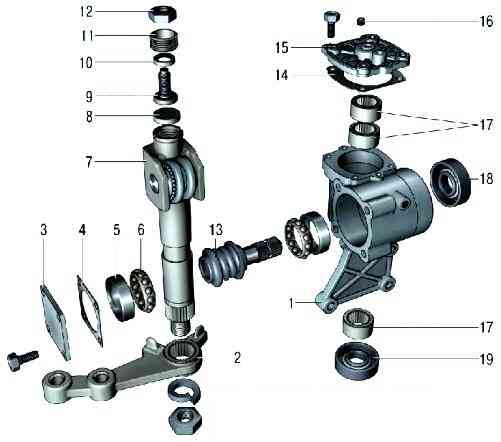

Drain the oil from the steering mechanism by unscrewing the plug 16 (see Fig. 3) of the oil filler hole and turning the mechanism upside down.

Unscrew the nut securing the steering arm and, having removed the spring washer, remove the bipod with a special puller.

Remove the mounting bolts and remove the cover 15 of the steering gear case together with the shaft 7 of the bipod.

Unscrew the nut 12 and, screwing the adjusting screw 9 into the cover 15, separate the cover and the bipod shaft 7.

Remove the mounting bolts and remove the cover 3 of the worm shaft thrust bearing together with the shims 4.

Using a worm 13, push out the outer ring 5 of the bearing from the crankcase and remove the shaft together with the cage 6 of the bearing.

Remove 1 oil seal 18 of the worm shaft and oil seal 19 of the bipod shaft from the crankcase.

With a suitable mandrel, press the outer ring of the upper bearing of the worm shaft out of the crankcase.

Remove bearings 17 from crankcase 1 and cover 15.

Carefully inspect the working surfaces of the roller and worm for signs of wear, jamming or scratches. Replace worn and damaged parts.

The ball bearings of the worm and roller must rotate freely, without seizing; there must be no wear and damage on the surface of the rings and balls.

Replace damaged bearings with new ones. If the roller rotates on the axis with binding or has play, replace the bipod shaft with roller assembly.

Assemble the steering gear in the reverse order of removal, observing the following conditions:

- after installing the worm in the steering gear housing and fixing the bottom cover 3, check the friction torque of the worm with a dynamometer, it should be 19.6–49.0 N cm (2–5 kgf cm).

If the torque is less than the specified, reduce the number of shims 4, and if more - increase;

- after installing the bipod shaft, make sure that there is no play in the engagement of the roller with the worm in the positions of the shaft turned to the right or left by 30 ° from the neutral position of the bipod. If there is a gap, eliminate it with the adjusting screw 9;

- after adjusting the gap in the engagement of the roller and the worm, check the friction moment of the worm shaft with a dynamometer, which should be equal to 68.7–88.3 N cm (7–9 kgf cm) when the worm shaft is rotated 30 ° as to the left , and to the right of the middle position and should gradually decrease to 49 N cm (5 kgf cm) when turning from an angle of 30 ° to the stop.

Fill the steering gear with oil.

Checking and adjusting the clearance in the bearings of the steering gear worm on a car

Set the front wheels to straight ahead.

Turning the steering wheel in both directions, check if there is any axial movement of the worm shaft 13 (see Fig. 2) relative to the crankcase 1 of the steering mechanism.

The presence of axial movement of the worm shaft is a sign of clearance in the worm bearings.

If axial movement is felt, turn the steering wheel 1 to 1.5 turns to the left.

Remove the bolts securing the bottom cover 3 and drain the oil from the steering gear housing.

Remove the bottom cover, remove one of the shims 4 or replace it with a thinner one.

Fix the bottom cover and check if there is any axial movement of the worm in the bearings. Shims are supplied with a thickness of 0.10 mm; 0.15 mm; 0.30 mm; 0.50 mm.

If there is no movement, fill the steering gear with gear oil.

Checking and adjusting the clearance in the engagement of the roller with the worm of the steering mechanism on the car

Check for axial movement of the worm in the bearings.

Using a puller, press the tie rod ball pins out of the holes in the bipod.

Disconnect the tie rods from the bipod while keeping the front wheels straight.

While swinging the bipod, check if there is a gap in the engagement of the roller and the worm.

Within the steering wheel turn of 30° to each side of the neutral position, there should be no gap, that is, a noticeable free play of the bipod.

If you feel free play of the bipod, loosen the nut 12 (see Fig. 2) of the adjusting screw 9.

Tighten the adjusting screw until the gap is eliminated.

Hold the adjusting screw with a screwdriver and tighten the nut 12.

Make sure the bipod does not move and attach the tie rods to it.