On a Gazelle car, steering can be installed both without power steering and with power steering

Non-power steering

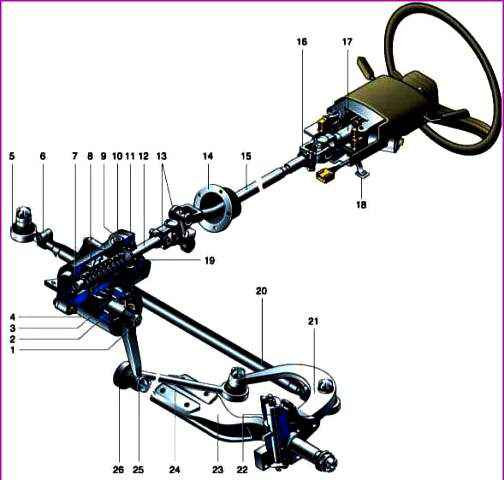

The car is equipped with steering, consisting of a steering column with a wheel, a steering gear and a steering drive.

The steering column allows you to change the position of the steering wheel in height and angle.

The upper end of the steering column shaft is connected to the steering wheel with conical splines, and the lower end is connected to the steering gear screw through cardan joints.

The steering mechanism consists of an aluminum crankcase, a screw with a ball nut and a sector shaft.

Steering: 1 - bipod mounting nut; 2 - roller bearing of the shaft-sector; 3 - shaft-sector; 4 - steering gear housing; 5 - tip of the transverse steering rod; 6 - clamp; 7 - lower screw bearing; 8 - ball nut; 9 - oil filler plug; 10 - shims; 11 - upper crankcase cover; 12 - screw; 13 - lower universal joints; 14 - steering shaft seal; 15 - shaft; 16 - upper universal joint; 17 - steering column; 18 - steering column lock handle; 19 - upper screw bearing; 20 - transverse steering rod; 21 - rotary lever; 22 - kingpin; 23 - front axle beam; 24 - longitudinal steering rod; 25 - bipod; 26 - hinge

The screw is mounted in the crankcase on two angular contact ball bearings.

A ball nut is installed on the screw, which has a screw groove inside.

A set of balls is placed between the nut and the screw. When the screw rotates, the balls roll along the helical groove and the ball nut moves along the screw.

At the same time, with its teeth, the nut turns the sector shaft mounted in the crankcase on two roller bearings.

A steering arm is fixed on the conical splines of the sector shaft.

The ball screw and ball set are matched to each other and can only be replaced as a unit if necessary.

The engagement of the ball nut with the sector shaft is adjusted by turning the eccentric cages of the sector shaft bearings.

The steering mechanism is lubricated with gear oil (0.5 l) filled into the crankcase through a plug with a conical thread.

The steering gear consists of a bipod, a longitudinal and transverse steering rods, wheel steering knuckle levers and steering rod joints.

The steering arm is connected by a longitudinal link to the steering knuckle arm of the left front wheel.

A tie rod connects the levers of both wheels, synchronizing their turn.

Its length can be adjusted, which allows you to change the toe angle.

The angle of longitudinal and transverse inclination of the axis of rotation and the camber of the front wheels are set by the design of the front suspension and are not adjustable during operation.

All hinges connecting the elements of the steering gear are unified, non-separable and do not require maintenance in operation.

Power steering combined with steering mechanism

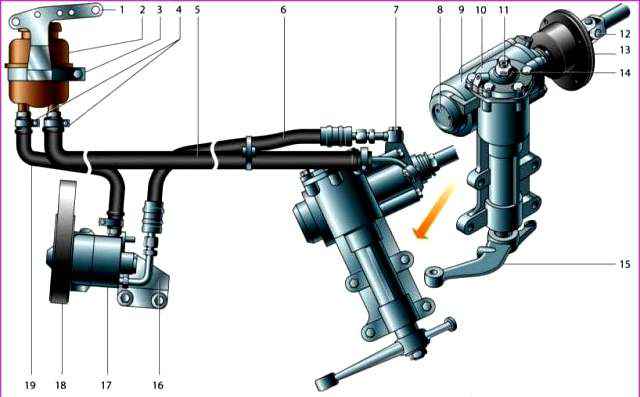

Hydraulic power steering system: 1 - tank bracket; 2 - tank; 3 - a collar of fastening of a tank; 4 - hose clamps; 5 - outlet hose (low pressure); 6 - injection hose (high pressure); 7 - bolt fitting; 8 - adjusting nut; 9 - steering mechanism; 10 - cover; 11 - adjusting screw; 12 - cardan joint; 13 - sealant; 14 - locknut; 15 - bipod; 16 - pump bracket; 17 - pump; 18 - pump drive belt; 19 - suction hose.

In the steering mechanism with built-in hydraulic booster, instead of a roller, a three-tooth sector is cut on the bipod shaft, and the role of a worm is performed by a screw connected to a piston-rack mounted on two thrust bearings, the preload of which is regulated by a nut.

In the crankcase of the steering mechanism, a hydraulic booster cylinder is made, in which a piston-rack moves along the screw.

The piston is made integral with the ball nut and has teeth that engage with the teeth of the bipod shaft sector.

The piston divides the cylinder into two cavities. When the steering wheel is stationary, the pressure in them is the same.

Depending on the direction of rotation of the steering wheel, the corresponding cylinder cavity is connected through a hydraulic distributor to the high-pressure supply line, and the other to the outlet line.

The pressure of the liquid (oil) in the hydraulic system of the power steering creates a vane-type pump with a belt drive from the crankshaft pulley, mounted on the front of the engine.

In the expansion tank of the hydraulic system the power steering is equipped with a filter element that traps particles larger than 45 microns.

The steering gear consists of steering trapezoid rods, bipod rods and levers.

Self-tightening collapsible hinges with hemispherical fingers are pressed into the eye of the pendulum lever and into the ends of the rods.

The tie rods of the steering trapezoid have adjusting tubes, and corrugated rubber seals with a metal clip are pressed on the shoulders of their tips.

The hinges of the bipod rod and the pendulum lever are protected by cap rubber seals.

Diagnosis of malfunctions of the power steering

- Cause of malfunction

Remedy

Increased steering wheel freeplay:

- Increased clearance in the engagement of the nut-sector pair

Adjust the engagement of the nut-sector pair

- The appearance of a gap in the propeller bearings

Adjust screw bearing

- Excessive wear of the part of the hinges of the rods and their fastening

Replace worn parts

- Increased wheel hub play

Adjust wheel bearing clearance

- Loosening the wedges of the forks and the nuts of the bipod

Tighten loose nuts

Steering, squeaking or clicking:

- Excessive wear of the screw or shaft-sector, chipping or dents on their surface

Replace the screw nut or sector shaft

Weak fixation of the steering column:

- Loosening the column locking mechanism

Adjust column locking mechanism

Increased steering force "heavy steering wheel":

- Kingpin bushing scuff

Replace bushings and kingpin

- Turning the kingpin bushings in the knuckle bosses

Replace bushings and kingpin

- Pollution of the pivot bearing (when turning the wheels, a creak is heard in the thrust bearing)

Rinse the thrust bearing through a grease fitting with a mixture of 50% kerosene and 50% gear oil.

Lubricate the support bearing through the grease fitting until grease comes out from under the seal

Grease leaking from the steering gear:

- Wear or loss of elasticity of the stuffing box and steering gear seals

Replace worn oil seal and O-rings

Steering column play:

- Axial movement of the steering wheel shaft relative to the covers

Replace worn steering column bearing bushings

Diagnosis of malfunctions of the power steering

- Cause of malfunction

Remedy

Constant noise from the pump:

- Worn bearings

Replace bearings

The amplifier does not work or its efficiency is low (increased force on the steering wheel):

- The filter in the tank is clogged

Replace the filter (on some engines, the filter is replaced with the tank assembly) and, preferably, the fluid

- Flow and safety valves clogged

Rinse valves and pump

- The belt slips over the pump pulley

Tighten or change the belt

- Liquid of inappropriate viscosity is filled (as a rule, its viscosity is low)

Change fluid

The steering wheel turns much easier in one direction than in the other:

- Clogging of the hydraulic system

Rinse hydraulic system and booster

- Amplifier defect: destruction of its parts, valve leaks

Replace amplifier assembly

Liquid leak from the system:

- Worn oil seals

Replace oil seals

- Hose cracks, their clamps are loose

Tighten clamps, replace rods

- Leak from under the covers of the amplifier or pump

Replace gaskets, rubber rings

- Leakage through technological holes in the pump casing (squeezed out the plugs)

Press in new plugs or replace pump

- Increased pressure in the system due to the flow valve jamming in the closed position

Repair or replace pump

- Excessive liquid level in the reservoir

Take off excess liquid with a syringe or rubber bulb

Low directional stability at high speed:

- Violation of the adjustment of the bearings of the screw and in a pair of nut-rail - shaft-sector of the steering mechanism

Adjust gaps between parts