Before replacing a gearbox, make sure it needs to be replaced by doing a road test

Perform the test on a suburban highway in the absence of heavy traffic, observing the necessary precautions.

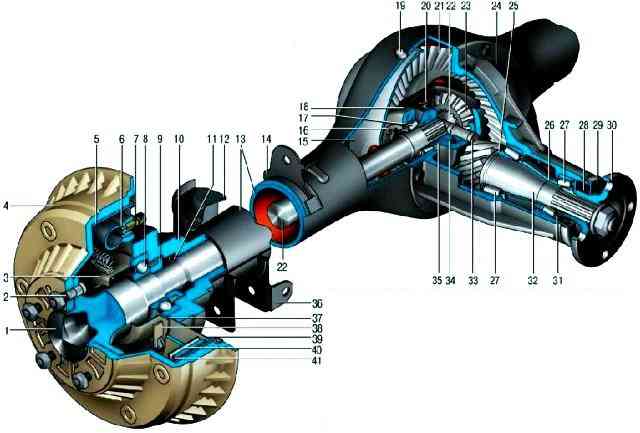

Fig. 1. Rear axle: 1 - decorative cap; 1 - stud fastening the brake drum and wheel; 3 - half shaft bearing oil deflector; 4 - brake drum; 5 - cast-iron drum ring; 6 - working cylinder of the rear brake; 7 - fitting for bleeding the brakes; 8 - half shaft bearing; 9 - locking ring of the bearing; 10 - rear axle beam flange; 11 - stuffing box; 12 - suspension spring cup; 13 - rear axle beam; 14 - mounting bracket for the upper longitudinal rod of the rear suspension; 15 - axle guide; 16 - differential bearing adjusting nut; 17 - differential box bearing; 19 - breather; 20 - satellite; 21 - driven gear of the main gear; 22 - axle shaft; 23 - axle gear; 24 - crankcase of the rear toast gearbox; 25 - adjusting ring; 26 - bearing spacer; 27 - drive gear bearings; 28 - drive gear oil seal; 29 - mud deflector; 30 - flange; 31 - oil deflector; 32 - main gear drive gear; 33 - axis of the satellites; 34 - support washer of the axle gear; 35 - differential box; 36 - bracket for fastening suspension parts; 37 - plate for mounting the axle shaft bearing; 38 - holder of bolts for fastening the plate; 39 - rear axle shield; 40 - rear brake pad; 41 - brake pad

1. Drive at a speed of about 20 km/h. Identify and remember the characteristic noises when moving.

Then gradually increase your speed to 90 km/h in your accelerating mode.

Listen to different noises at the same time and notice the speed at which they appear and disappear.

2. Release the throttle pedal and, without using the brakes, dampen the speed with engine braking.

While slowing down, watch for changes in the noise, as well as intervals at which the noise appears more.

Typically, the noise comes and goes at the same speeds, both when accelerating and when decelerating.

3. Accelerate the vehicle to approximately 100 km/h, place the gearshift lever in neutral, turn off the ignition and let the vehicle roll freely to a stop.

Be careful when turning off the ignition. Only turn the key to the off position.

Otherwise, the anti-theft device may work, the steering mechanism will be locked and the car will become uncontrollable.

Also note that when the engine is not running, the effectiveness of the braking system (due to the disconnection of the vacuum booster) and steering (if the machine is equipped with a hydraulic booster) are reduced.

4. The noise noticed during this test and corresponding to that noticed during test 1 (operations 1 and 2) does not come from the gearbox.

An unloaded gearbox cannot be a source of noise, except for noise caused by bearings.

5. Noise noted during test 1 (operations 1 and 2) and not repeated during test 2 (operation 3) may come from the gearbox, axle shafts or bearings.

Continue testing.

6. With the vehicle stationary and braked, start the engine and, gradually increasing the crankshaft speed, compare the observed noises with the noises of the two previous tests.

The noises observed during this test, which correspond to the noises of the first (operations 1 and 2) tests, do not apply to the gearbox.

They can be caused by other components and assemblies of the car.

7. Hang the rear wheels, place the car on supports.

Start the engine and shift to 4th gear.

Note the noises when the engine is running at different engine speeds.

8. Noises detected during the first test (operations 1 and 2) and not repeated during subsequent tests come from the gearbox.