Replace hoses and lines if damaged

In addition, we recommend prophylactic replacement of hoses after every 60,000 km or after 3 years of vehicle operation, even if they are not damaged externally.

The rubber on the hoses ages and they can burst unexpectedly when braking.

Replacing hoses

You will need: keys "for 10", "for 14", "for 15", "for 17", pliers, screwdriver.

Four brake hoses are used on the car: two (rear) - to connect the pipelines on the rear axle housing and two front - to connect the pipelines to the brake cylinders of the front brake mechanisms.

On the rear axle housing, holding the rear hose fitting with a 17 wrench, unscrew the pipe nut with a wrench for brake pipes and disconnect it

To prevent complete leakage of fluid from the hydraulic actuator, immediately plug the tube opening in any way possible.

Protective valve caps for venting valves are very well suited for this purpose.

Unscrew the hose fastening nut and remove the hose from the bracket on the body.

Install the new hose in the reverse order of removal.

Replace the second rear hose in the same way.

Do not twist the hoses along the axis.

Holding the front hose fitting with a 17 wrench, unscrew the pipe nut with a wrench for brake pipes and disconnect it.

Remove the rubber seal with the hose from the bracket

Unscrew the hose connecting the pipeline to the front brake cylinder manifold

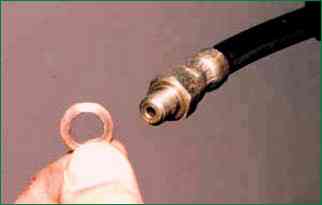

When installing the hose, be sure to place the copper gasket under the ferrule attached to the manifold.

Install the new hose in the reverse order of removal.

Replace the second front hose in the same way.

After replacing the hoses, bleed the brake system (see "Bleeding the hydraulic brake system ").

Replacing pipelines

The piping connections to all brake system components and hoses are the same. The design of all pipelines and the principle of their replacement are the same.

The work is shown on the example of a pipeline connecting the tee to the wheel cylinder of the rear brake mechanism.

Use special wrenches to loosen pipeline nuts, as the nuts are overtightened and usually corroded, as a result of which, when using ordinary wrenches, the edges of the nuts are crushed.

Unbend all the pipe fastening brackets, unscrew the nuts of the brackets and remove the pipelines from them

Unscrew the nuts securing the ends of the pipelines and remove the pipeline

Install the new piping in the reverse order of removal

To prevent complete leakage of fluid from the hydraulic actuator, immediately plug the tube opening in any way possible.

Protective valve caps for venting valves are very well suited for this purpose.