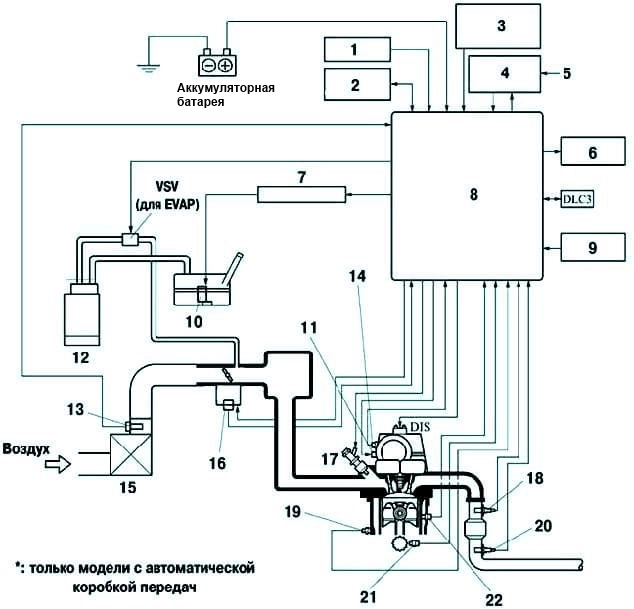

The electronic engine control system consists of sensors for engine and vehicle condition parameters, a controller and actuators

The controller is the central unit of the engine management system.

It receives information from sensors and controls the actuators, ensuring optimal engine operation at a given level of vehicle performance.

The controller controls actuators such as fuel injectors, motorized throttle, ignition coil, oxygen sensor heater, canister purge valve, and various relays.

The controller controls the on and off of the main relay (ignition relay), through which the supply voltage from the battery is supplied to the elements of the system (except for the electric fuel pump, electric fan, control unit and APS status indicator).

The controller turns on the main relay when the ignition is turned on.

When the ignition is turned off, the controller delays turning off the main relay for the time necessary to prepare for the next turn on (completion of calculations, setting the throttle to the position before starting the engine).

When the ignition is turned on, the controller, in addition to performing the functions mentioned above, exchanges information with the APS (if the immobilization function is enabled).

If the exchange determines that access to the vehicle is allowed, then the controller continues to perform engine control functions.

Otherwise, the engine will be blocked.

The controller also performs a system diagnostic function.

It determines the presence of malfunctions of system elements, turns on the alarm and stores codes in its memory that indicate the nature of the malfunction and help the mechanic to carry out repairs.

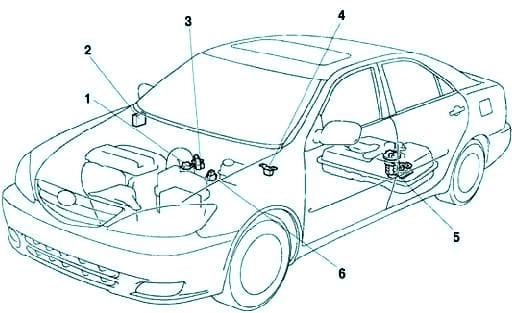

Figure 2. shows the location of the main elements of the engine control system on a car.

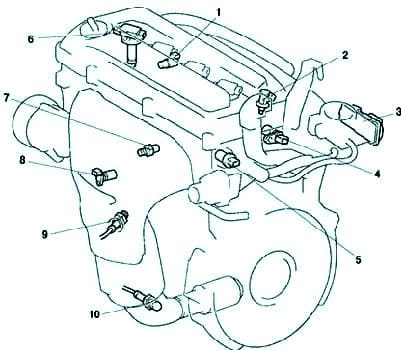

Fig. 3. Location of the main elements of the engine control system on the engine: 1 - control valve for the variable valve timing system; 2 - fuel injector; 3 - throttle position sensor; 4 - camshaft position sensor

The location of the main elements of the engine management system on the engine is shown in fig. 3.

See another article - Toyota Camry engine management system