Remove the fuel rail and injectors for flushing or replacement

We prepare the car and relieve the fuel pressure in the fuel supply system, as indicated in the previous article

Disconnect the negative battery terminal

Remove the decorative engine cover

Remove the air filter cover assembly with the air supply sleeve

Remove the plastic safety cover of the fuel line coupling

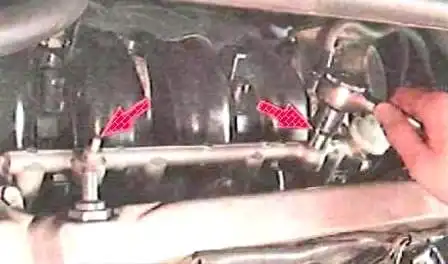

Insert the tool into the gap between the fuel line coupling and the pipe of the fuel pressure pulsation compensator

After that, disconnect the fuel line from the fuel rail

To disconnect the fuel line, the tool must compress the four spring clips inside the coupling

Disconnect the hose of the large branch of the crankcase ventilation system from the non-return valve by squeezing the bent ears of the clamp with your fingers

Remove the two fuel injector harness holders from the fuel rail mounting bolts

Disconnect the wire blocks from the fuel injectors and take the harness away from the fuel rail

We unscrew the two bolts securing the fuel rail to the cylinder head

And remove the fuel rail

Remove the spacers installed under the ramp

If, when removing the ramp, the nozzles remained in the intake pipe, take them out

Install the fuel rail and all removed parts in reverse order, replacing the O-rings

Removing, checking and installing injectors

Possible signs of injector failure:

- - unstable engine operation;

- - difficulty starting the engine;

- - stop the engine at idle;

- - the engine does not develop full power;

- - jerks and dips in the engine;

- - increased fuel consumption;

- - increased content of CO and CH in exhaust gases;

- - glow ignition due to leakage of injectors

Remove the fuel rail as described above

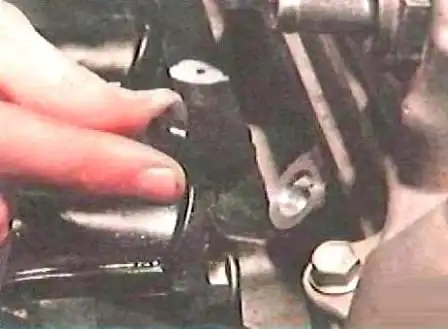

Remove the injectors from the holes of the fuel rail

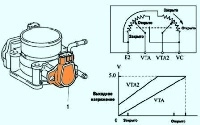

Check the resistance of the injector winding by connecting the probes of the autotester to the winding terminals

The resistance of a good injector should be 11.6-12.4 ohms.

If the resistance is not correct, you need to replace the nozzle

Checking the nozzle according to the shape of the spray of the fuel jet and for tightness should be carried out at specialized service stations

Before installing the injectors, we replace the upper and lower sealing rings

If we install the old nozzles, then you need to wash their sprayers with a solvent or carburetor cleaner

Install the nozzles in reverse order.

Before installing the injectors, lubricate the O-rings with engine oil

Check the tightness of the connections and install all the parts in reverse order