Preparing the car for the task

Drain the brake fluid.

For models with a 1MZ-FE engine, the air cleaner assembly must be removed before starting work.

Disconnect the brake fluid level indicator sensor connector.

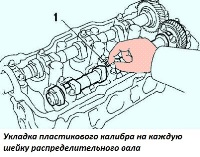

Using the special tool 09023-00100, disconnect the brake pipes from the brake master cylinder by unscrewing the 6 union nuts (fig. 1).

Unscrew the two fastening nuts, remove the fitting, brake master cylinder and gasket (Fig. 2).

Remove the cap and remove the strainer from the master cylinder reservoir.

Unscrew the fastening screw and remove the tank.

Remove the two O-rings.

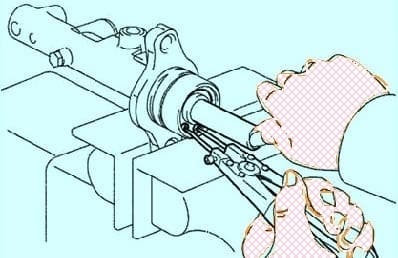

Place the cylinder in a vise.

Disassembly

Using a screwdriver, push the pistons all the way through, unscrew the locking bolt and remove the O-ring.

Wrap the screwdriver with plaster or tape to prevent damage to the pistons and cylinder bore.

Press the piston with a screwdriver and use the circlip pliers to remove the circlip (fig. 4).

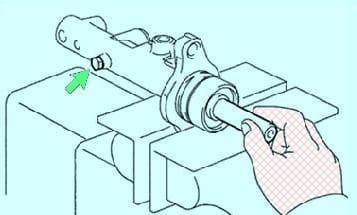

Unscrew the locking piston bolt with a gasket and remove piston No. 1 with a spring, pulling it strictly along the axis without distortion (Fig. 5)

If the piston is removed at an angle, the cylinder bore may be damaged.

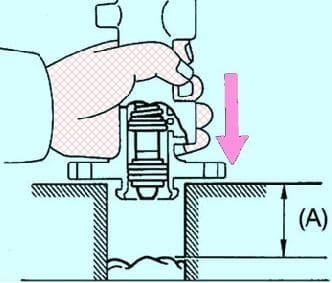

Place a rag on two wooden blocks and lightly strike the cylinder flange against the blocks until the number 2 piston comes out.

Make sure that the distance (A) indicated in Figure 6 from the rag to the top of the bars was at least 100 mm.

Check and Install

Check for rust and scratches on the cylinder mirror.

Inspect the cylinder for wear and damage. If necessary, replace the cylinder.

Replace all parts included in the repair kit used to service the brake master cylinder.

When installing, lubricate the rubber parts with clean brake fluid to facilitate assembly.

Do not use factory compressed air to dry or clean brake parts.

This may damage the rubber parts.

If any part of the hydraulic system is removed or disconnected, bleed the brake system completely.

Perform all repairs on a clean workbench free of mineral oil stains.

Install all components in the reverse order of removal.