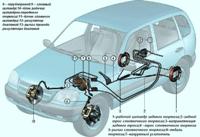

In a variant, ABS brakes are installed on the car

The anti-lock braking system is part of the car's service brake system and is designed to automatically control the degree of wheel slip in the direction of their rotation during braking by changing the pressure of the brake fluid in the working brake cylinders in order to prevent loss of vehicle control and stability and increase braking efficiency.

ABS also performs the functions of distributing braking forces along the axes of the car and distributing braking forces along the sides of the car when braking in a turn.

ABS consists of the following main units:

- - hydraulic unit;

- - two front wheel speed sensors;

- - two rear wheel speed sensors;

- - two front wheel rotors. The front wheel rotor is part of the outer joint;

- - two rear wheel rotors. The rear wheel rotor is part of the half shaft;

The hydraulic unit structurally consists of an electronic control unit and a hydraulic modulator containing electromagnetic valves, a return pump and a return pump electric motor.

Wheel speed sensors generate signals about the speed of each wheel of the vehicle, which are transmitted to the electronic control unit of the hydraulic unit.

The wheel sensors are based on the principle of electromagnetic induction.

When the wheel rotates, the teeth and cavities of a special rotor pass by the sensor and induce an electrical signal in the sensor winding, the frequency of which is proportional to the angular velocity of the wheel and the number of teeth on the rotor.

The electronic control unit performs logical processing of signals about the speed of the wheels and, depending on their condition (excessive acceleration or deceleration of the wheel), sends control commands to the hydraulic modulator.

According to the commands received, the hydraulic modulator, by turning on or off the solenoid valves, reduces, increases or maintains a constant pressure of the brake fluid in the wheel brake cylinders, thereby ensuring optimal regulation of the braking forces.

When the pressure is reduced, excess brake fluid is pumped by the return pump to the brake master cylinder.

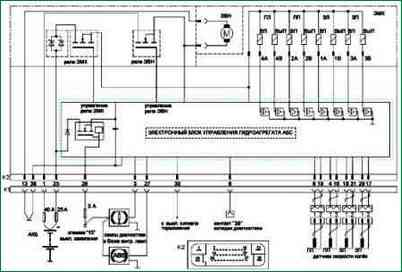

1 – EMC relay; 2 – EWH relay; 3 - EVN; 4 - EMC; 5 – EWH relay control; 6 – EMC relay control; 7 – wheel speed sensors; 8 - contact (39) of the diagnostic block; 9 - to the brake signal switch; 10 - diagnostic lamps in the block of control lamps; 11 - terminal (15) of the ignition switch; 12 - battery

The ABS schematic diagram is shown in the figure

Assignment of the pins of the hydraulic unit connector:

Contact - Circuit

- 1 - Terminal "+" battery. Power supply voltage EWH of the hydraulic unit.

- 3 - Output to the lamp for diagnosing the electronic brake force distribution.

- 4 - Front right DSC input.

- 6 - K-line output/input.

- 8 - Front left DSC input.

- 13 - "Mass". Common power supply wire for EWH of the hydraulic unit.

- 16 - Front right DSC supply voltage.

- 17 - Rear right DSC power supply.

- 18 - Rear left DSC input.

- 19 - Front left DSC supply voltage.

- 25 - Battery "+" terminal. Power supply voltage of the EMC of the hydraulic unit.

- 27 - Output to the anti-lock brake system diagnostic lamp.

- 28 - Terminals "15" of the ignition switch. Power supply voltage of the HA computer.

- 29 - Rear right DSC input.

- 30 - Input from brake light switch.

- 31 - Supply voltage of the rear left DSC.

- 38 - "Mass". Common power supply wire for the EMC and the ECU of the hydraulic unit.

ABS diagnostics

The Anti-Lock Brake System (ABS) warning light illuminates amber briefly when the ignition is turned on.

This indicates that the self-test has been completed and that the and indicator lamps.

In cases where:

- the lamp does not light up when the ignition is turned on, it lights up and does not go out, it lights up while driving, there may be malfunctions in the system.

If the ABS lamp comes on, except during the self-test when the ignition is turned on, it indicates that the ABS is not working.

In this case, the operation of the hydraulic brake drive is not disturbed, but the brakes in the car will work as if there were no ABS in the car.

The electronic brake force distribution warning lamp lights up briefly in red when the ignition is switched on, simultaneously with the ABS lamp.

This indicates that the system has performed a self-test and that the indicator lamp is working.

In cases where:

- the lamp does not light up when the ignition is turned on, it lights up and does not go out, it lights up while driving, there may be malfunctions in the system.

The ignition of the electronic brake force distribution lamp always occurs simultaneously with the ABS warning lamp.

If the ABS lamp and the electronic brake force distribution lamp come on at the same time, with the exception of the self-test when the ignition is turned on, it indicates a failure of all ABS functions.

To view fault codes and ABS parameters, use the DST-2, 10.12 diagnostic tool with the appropriate firmware.

List of ABS fault codes displayed by the diagnostic tool:

Code - Description of the code

- C0035 - Malfunction of the front left wheel speed sensor

- С0040 - Malfunction of the front right wheel speed sensor

- C0045 - Malfunction of the rear left wheel speed sensor

- C0050 - Malfunction of the rear right wheel speed sensor

- C0060 - Front Left Wheel Intake Valve Circuit Malfunction

- C0065 - Front Left Wheel Exhaust Valve Circuit Malfunction

- C0070 - Front Right Wheel Intake Valve Circuit Malfunction

- C0075 - Front Right Wheel Exhaust Valve Circuit Malfunction

- C0080 - Rear Left Wheel Intake Valve Circuit Malfunction

- C0085 - Rear Left Wheel Exhaust Valve Circuit Malfunction

- C0090 - Rear Right Wheel Intake Valve Circuit Malfunction

- C0095 - Rear Right Wheel Exhaust Valve Circuit Malfunction

- C0110 - Hydro unit pump motor circuit failure

- C0121 - Valve relay circuit malfunction

- C0161 - Brake switch circuit failure

- C0245 - Wheel speed sensor frequency error

- С0550 - ECU malfunction

- С0800 - Malfunction of the power supply of the device

- С0640 - Incorrectly programmed information in EEPROM or defective EEPROM cell

If fault codes C0035, C0040, C0045 and C0050 are found, check the electrical circuits to the corresponding DSC for an open and short circuit, check the supply voltage of the corresponding DSC (U supply DSC ≥ 0.8 U supply ECU).

If a fault code C0110 is found, check the supply voltage on pin 1 of the harness block to the hydraulic unit.

If a fault code C0121 is found, check the supply voltage on track 25 of the harness block to the hydraulic unit.

If DTC C0161 is found, check the circuit to the brake light switch for an open or short.

On pin 30 of the block of the harness to the hydraulic unit should be:

- low-level input voltage no more than 0.3 U pit;

- high-level input voltage of at least 0.8 U supply

If DTC C0245 is found, check the reliability of the fastening of the DSC and the clearances between the DSC and the rotor.

The gap between the front wheel speed sensor and the front wheel rotor teeth should be 0.72-1.33mm.

The gap between the rear wheel speed sensor and the teeth of the rear wheel rotor should be 0.13-1.12 mm.

If DTC C0800 is found, check the supply voltage on track 28 of the harness connector to the hydraulic unit. It should be within (10-16) V.

If fault codes C0060, C0065, C0070, C0075, C0080, C0085, C0090, C0095, C0550 are found, replace the hydraulic unit.

The fault corresponding to code C0640 is not critical. In case of its occurrence, further operation of the car is allowed.

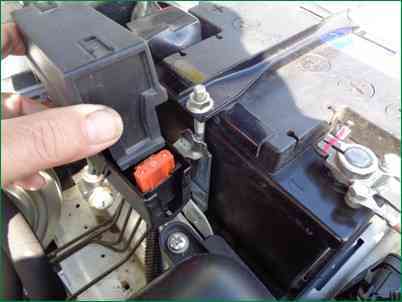

ABS fuse box

The ABS fuse box is located in the engine compartment on a bracket next to the battery

- 40A - ABS hydraulic unit return pump motor

- 25 A - ABS hydraulic unit solenoid valves

- 5A - Electronic control unit for ABS hydraulic unit

To change the fuses, We hold the ABS fuse box cover retainer

Open the block cover and replace the fuse (the cover opens up)