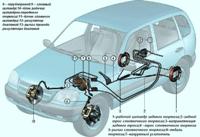

In the fuel injection system of the engine, the pressure is 30 MPa (3 kgf / cm 2).

Therefore, it is forbidden to loosen the fuel line connections while the engine is running or immediately after it has stopped.

To carry out work on the repair of the power supply system on a just stopped engine, it is necessary to first reduce the pressure in the power supply system.

2-3 hours after the engine stops, the pressure in the system drops to almost zero.

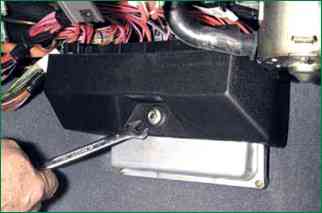

You will need a "10" key (preferably a socket).

There are two ways to reduce the pressure in the power system.

In the first method, inside the passenger compartment, unscrew the nut of the engine control unit cover and remove the cover.

Remove the fuel pump fuse.

You can remove the fuel pump relay

Start the engine and let it run until the fuel line runs out of fuel.

The engine will then stop.

Reinsert the fuse.

To reduce pressure, you can also use the control valve installed at the rear end of the fuel rail and closed with a plastic cap.

The valve has a design similar to the wheel tire valve spool.

Unscrew the cap and, by pressing the spool, drain the excess fuel.

After that, you can disconnect the fuel lines.

Be careful - high-pressure fuel will come out as a spray jet

You can also remove the hatch under the rear seat and remove the wiring harness block from the fuel module

Start the engine and also wait until the engine stalls after running out of fuel, and therefore relieves fuel pressure in the fuel line

Whatever method you like, you can use it to carry out work on the fuel system.