For disassembly, remove the gearbox from the car for this:

We install the car on a lift or a viewing ditch

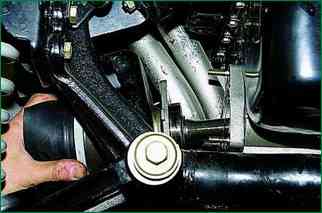

Remove the right front wheel drive

Remove the left front wheel drive

In this case, the gearbox remains suspended on the adjustable stop

Supporting the gearbox, remove the adjustable stop from under it and remove the gearbox

Before disassembling, we clean the gearbox.

Using a 10 spanner, unscrew the eight nuts securing the front cover to the gearbox housing.

Remove the cover

Remove the gasket

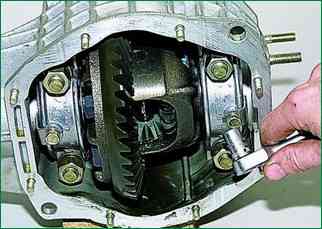

With a 10 head, unscrew the bolt securing the locking plate of the left differential bearing cover and remove the plate.

We also remove the lock plate of the right cover.

With a head of 19, we unscrew the four nuts securing the bearing caps of the differential box

Remove washers from studs

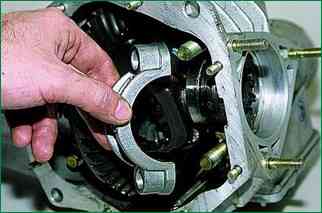

Pry off with a slotted screwdriver

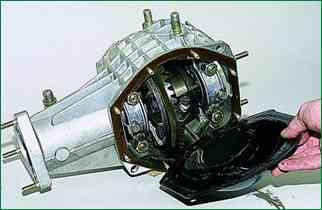

Remove the cover of the left bearing of the differential box.

To remove the right bearing cover, screw the bolt into the lock plate mounting hole and pull the bolt to remove the cover

Remove the adjusting nuts

Remove the differential box assembly with the main gear driven gear

Remove the final drive gear oil seal

Remove the oil deflector from the drive gear shank

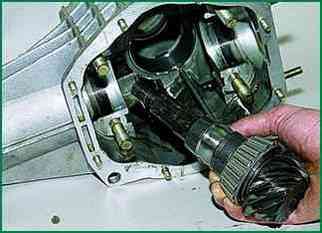

We take out the inner ring of the rear bearing of the drive gear with a separator and rollers

We take out the drive gear with the inner ring, separator, spacer sleeve and front bearing rollers.

By striking the drift with a hammer, we knock out the outer ring of the front bearing and remove the ring.

We also dismantle the outer ring of the rear bearing.

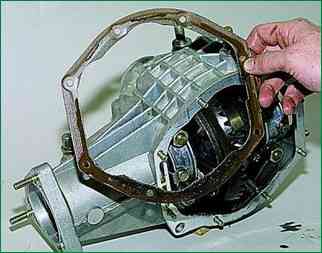

When oil leaks from under the lower cover of the front axle gearbox housing, with a 13 key, unscrew the eight bolts of its fastening and remove the cover.

The joint is sealed with sealant

Checking the technical condition of parts, as well as parts of the rear axle.

In addition, we check the condition of the ball bearings of the housings of the internal joints of the drives.

The bearings must not have damage on the raceways of the rings, on the separators and balls, as well as cracks and chips on the rings.

The radial clearance must not exceed 0.05 mm. There should be no cracks or signs of wear on the seats of the gearbox housing.

We replace worn and damaged parts with new ones.

We press in the new outer rings of the drive gear bearings with a piece of pipe or a tool head of a suitable diameter.

When installing a new pair of final drive gears, make sure that their gear ratio (marking on the gears is 2106) is equal to the gear ratio of the main pair of the rear axle gearbox.

To set the preload of the bearings of the differential box, sequentially and evenly tighten both adjusting nuts of the bearings so that the distance between the covers increases by 0.08-0.11 mm.

We clean the mating surfaces of the covers and the gearbox housing from the remnants of sealant and oil.

We replace the sealing gasket of the front cover of the gearbox housing with a new one.

We install the lower cover of the gearbox housing on the sealant.