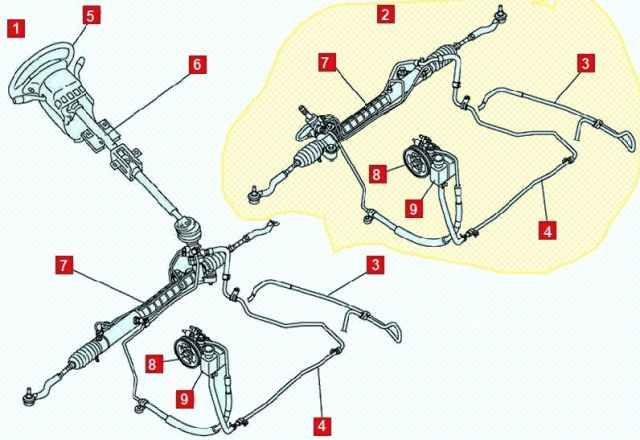

The steering consists of a steering wheel, a steering column, a steering mechanism, two steering rods connected by ball joints to the steering knuckles, pipelines and a pump

Rack and pinion steering with hydraulic booster and adjustable safety steering column

The rotation of the steering wheel is transmitted through the shafts of the steering column to the steering gear, which engages with the movable rack

The steering rack is connected to the steering knuckle levers by steering rods, through which it transmits power to the front wheels of the car

The length of the steering rods can be changed by screwing them in or out of the tips, thereby adjusting the convergence of the front wheels

The power steering pump creates pressure of the working fluid, thereby reducing the effort that the driver needs to apply to turn the steering wheel

On vehicles with a 1.6 engine, a belt-driven power steering pump is installed from the crankshaft pulley

On vehicles with a 2.0 engine, an electric power steering pump is installed, made as a single unit with the control unit for the power steering system

To reduce the force applied to the steering wheel to turn it, hydraulic power steering is installed on cars

As an additional force, a high-pressure fluid is used, which is supplied to the working cylinders located on the steering mechanism.

The control valve is used to inject fluid into the power cylinder under pressure, which corresponds to the angle of rotation of the steering wheel.

Diverter valves operate according to the so-called open center principle, i.e. when the control valve is inactive, the liquid supplied by the pump is bypassed back into the tank at zero pressure.

The pressure in the hydraulic system is generated by a pump driven by a belt from the engine crankshaft pulley.

Variable steering (depending on engine speed)

The design and operation of the steering system is largely derived from the 626 (GF), with the following exceptions.

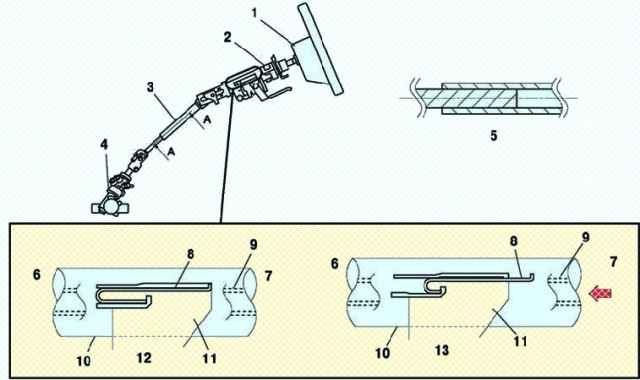

Mazda 3 vehicles use a telescoping mechanism with variable response.

The steering gear is connected to the steering shaft through an intermediate shaft (fig. 2).

During a collision, the intermediate shaft is destroyed when the steering mechanism is moved back, thus reducing the impact energy.

If the driver's body hits the steering wheel, the impact force is transferred from the steering wheel to the inner shaft, outer column and mounting bracket.

In this case, the mounting bracket is separated from the instrument panel and the entire steering shaft is shifted forward.

After that, the U-shaped plate, fixed to the instrument panel on one side and held by the mounting bracket on the other, deforms and absorbs the impact energy.