Check the brakes on a dry and level road, at various vehicle speeds with light and hard pressure on the brake pedal, avoiding brake lock and tire slip. Three main factors influence the braking process:

- on different wheels there will be different tire adhesion conditions with the road, which causes different braking forces

The air pressure and tire tread must be the same;

- – the braking forces on the front and rear axles must be proportional to the vertical loads acting on them;

- - wrong wheel alignment can cause the car to pull to the side when braking.

To check for brake fluid leakage, depress the brake pedal with the engine running at idle speed and the shift lever in neutral.

If the pedal drops gradually at constant pressure, there is a leak in the system.

Visually check for leakage and brake fluid level in the master cylinder reservoir.

A slight drop in the brake fluid level is due to normal pad wear.

Abnormally low level indicates a leak in the system.

In a hydraulic system, both internal and external leakage is possible. If the brake fluid level is normal, check the length of the brake booster rod.

If improper stem length is found, adjust length or replace stem.

Check the brake master cylinder in the following order:

- - for damage and leakage of brake fluid around the brake master cylinder.

A low brake fluid level can only indicate a leak.

Wetting of the surface of the brake master cylinder is also abnormal;

- - pedal rod connection and stem length.

If they are OK, disassemble the master cylinder and check for stretching or swelling of the cylinder seals, then for wear on the rubber parts.

If the seals are swollen, you may have used a non-standard or contaminated brake fluid.

If contaminated brake fluid is found, all metal components should be disassembled and cleaned, and all rubber components replaced.

All pipelines should also be flushed.

Incorrect brake fluid, mineral oil, or the presence of water in the fluid can cause brake fluid to boil or damage rubber components.

If the main piston seals in the master cylinder are swollen, then the rubber components are damaged.

If rubber wear is found, disassemble all parts of the hydraulic system and clean them with alcohol. Dry the parts with compressed air before assembling.

Replace all rubber parts in the system, including hoses. When operating the brake mechanism, check the absence of fluid in the gaskets.

If fluid is found, replace gaskets.

If the brake master cylinder piston seals are in good condition, check for leakage or excessive heat.

If these conditions are not found, drain the brake fluid, fill the brake master cylinder and re-drain the system.

Checking the brake fluid level

The brake fluid reservoir is located in the engine compartment.

The reservoir has a transparent body, so the brake fluid level can be controlled from the outside.

The brake fluid level should always be closer to the "MAX" mark.

If the brake fluid level is too low, before removing the cap from the expansion tank, wipe the cap and the area near the cap from dirt with a clean rag to prevent dirt from entering the hydraulic circuit of the brakes.

Add the recommended brake fluid to the reservoir. Mixing different types of brake fluid can damage the hydraulic system.

Brake hoses should be checked at least twice a year.

To prevent sudden failure of the brake system, carefully check the condition of all pipes and connections, paying special attention to the following:

Metal pipelines must be free of scratches and corrosion and must be away from sharp edges that could damage them.

The brake hose must be elastic, free of tears and cracks, and firmly embedded in the tips.

The threads of the hose ends must not be damaged.

If the hose swells when you press the brake pedal, the cords are broken. If any of these defects are found, the hose must be replaced.

Mineral oils and greases that dissolve rubber should not get on the hoses.

All piping fastening brackets must be intact and well secured.

Loosening or destruction of the brackets leads to vibration of the pipelines, which causes them to break.

Not leakage of brake fluid from the connections of the master cylinder with pipelines and reservoir is allowed.

If any defects are found, replace the damaged parts with new ones.

Replace flexible hoses, regardless of their condition, with new ones after 120 thousand kilometers or after five years of vehicle operation to prevent sudden ruptures due to rubber aging.

A brake hose rubbing against a suspension part wears out and eventually fails. Use a mirror and a backlight to check.

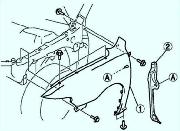

Vacuum hose valve check (brake booster)

Remove the clamps and the vacuum hose.

Alternately apply vacuum and pressure to the vacuum hose from the engine side and make sure that air can only flow in one direction (fig. 1.).

If air flows in both directions, replace the vacuum hose.

Possible malfunctions of the brake system

Brake fluid leak

The brake fluid level in the reservoir is constantly dropping. The malfunction is accompanied by an increased stroke of the brake pedal.

Possible reasons:

- - malfunction of the front brake caliper;

- - malfunction of the rear brake caliper;

- - damage to the brake hose of one of the wheels;

- - brake pipe damage

Increased brake pedal travel

Possible reasons:

- - brake fluid leak (see above);

- - the main brake cylinder is faulty

Increased effort on the brake pedal

Possible reasons:

- - malfunction of the vacuum booster;

- - lubrication of brake pads and the surface of brake discs of one axle

Uneven operation of the brake mechanisms (slip or skid during braking)

Possible reasons:

- - jamming of the front or rear brake caliper;

- - oiling the lining of the brake pads and the surface of the brake discs of one of the wheels;

- - brake line pinched

Strong creaking or grinding when braking

Possible reasons:

- a creak or rattle, most likely caused by the wear limit of the friction linings of the brake pads of the front or rear brake mechanisms