- How to replace hydraulic lifters VAZ-2123

- Diesel oil filter D-245

- How to remove and install the flywheel of the ZMZ-406 engine

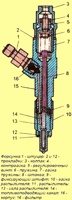

- Features of the D-245.12 diesel engine

- Requirements for parts of the crank mechanism D-245.12

- Installation of gas distribution phases VAZ-2123

- Replacing the crankshaft ZMZ-406

- Troubleshooting engine parts VAZ-21126

- How to replace the cylinder head gasket VAZ-2123

- Removal, installation and repair of the crankshaft ZMZ-409

- Technical characteristics of the pump TNVD - 4UTNI-T-1111005-50 diesel D-245

- Generator G250P2 and generators 665.3701-01 and 161.3771

- Dismantling diesel D-245

- Replacing the cylinder head gasket ZMZ-409

- Repair of the water pump ZMZ-409

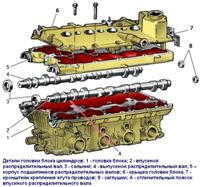

- Engine design VAZ-21126

- Features of the carburetor DAAZ 2107

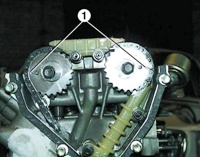

- Camshaft drive ZMZ-406

- ZMZ-409.10 engine and its technical characteristics

- Removal and installation of thermostat ZMZ-409

- Installation of the gas distribution mechanism D-245

- Assembly of diesel D-245

- The principle of operation of the K-88 carburetor

- Removal, repair and installation of the intermediate shaft ZMZ-409

- Carburetor repair K-131

- Diesel oil system D-245

- Detection of the cylinder block D-245

- Repair of the connecting rod and piston group ZMZ-402

- Repair of the cylinder head of the VAZ-21126 engine

- Removal and installation of a viscous coupling ZMZ-409

- Replacement of cylinder liners for diesel D-245

- Carburetor adjustments and checks 21083

- D-245 diesel turbocharger

- How to disassemble and assemble the K-151 carburetor

- Carburetor K-151 adjustment

- Removal and installation of camshafts ZMZ-409

- Description of the assembly of the ZMZ-402 engine

- Features of the cooling system D-245

- Removal and installation of the crankshaft ZMZ-402

- Installation of pistons and rings diesel D-245

- Repair of the oil pump ZMZ-409

- Repair and replacement of the ZMZ-406 piston engine

- Adjustment of the ignition moment of the ZMZ-402 engine

- Installation of cylinder head and valve mechanism D-245

- How to remove and install the cylinder head ZMZ - 402

- Removal and installation of the ZMZ-406 alternator belt

- Removal and installation of the ZMZ-402 engine distributor

- Fuel system of the ZMZ-402 engine

- Removal and installation of the ZMZ-406 engine

- The sequence of disassembly of the ZMZ-402 engine