The front wheel brakes are disc brakes with a three-piston floating caliper

The cylinder block is fixed in the caliper in two guides and fixed with a spring-loaded retainer.

Between the cylinder block and the caliper there are pads: the inner pad rests on the cylinder pistons, the outer pad rests on the caliper boss.

The caliper can move in the shoe guide by being pressed against it by two spring-loaded levers.

The shoe guide is rigidly attached to the steering knuckle with two bolts.

The bolts are fixed against loosening by the edges of the protective cover (they are bent on the edges of the bolts after tightening).

The minimum thickness of the disc during wear is 9.5 mm, the maximum allowable end runout (on the largest radius) is 0.15 mm.

The minimum allowable thickness of the front brake pads is 1.5 mm.

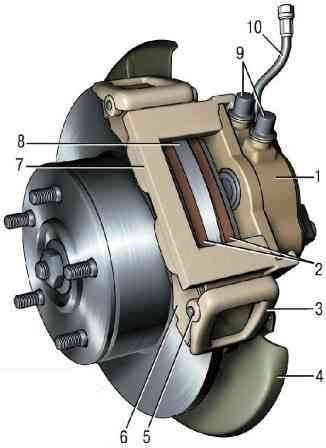

The brake mechanism of the front wheel (fig. 1) is a disc brake with a floating three-piston caliper.

Cylinder block 1 is fixed in the caliper on two guides and secured with a spring retainer.

Brake pads 2 with steel bases, shaped to fit snugly against the pad guide.

When installing the pads, spring-loaded levers 3 press the caliper 7 against the ends of the pads, which ensures that the pads are constantly pressed against the grooves of the guide.

Brake disc 8 is made of cast iron.

When braking under the action of fluid pressure in the hydraulic drive, the pistons move the inner brake pad relative to the guide and caliper and press it against the brake disc.

At the same time, under the influence of fluid pressure, the cylinder block moves along with the caliper along the bevels of the guide and clamping levers.

In this case, the caliper moves the outer brake pad relative to the guide and presses it against the brake disc.

Both brake pads are pressed against the brake disc with the same force, since the pressure of the fluid on the pistons and the bottom of the cylinder block is the same.

After the brake stops and stops, the fluid pressure on the pistons and the bottom of the cylinder block drops sharply.

Due to the elasticity of the rubber rings, the pistons are retracted from the inner brake pad, which at the same time moves away from the brake disc due to its runout.

At the same time, the outer brake pad, together with the caliper, also moves away from the brake disc as a result of its beating.

When the friction linings of the brake pads are worn, the gap between the linings and the brake disc increases.

When braking under the action of fluid pressure, the pistons will move relative to the sealing rings and take a new position in the cylinders, which will compensate for the wear of the friction linings.

After stopping braking, the brake pads will move away from the brake disc by the same amount, determined by the deformation of the rubber rings.

In this way, a constant gap between the brake pads and the disc is automatically maintained. In this regard, during operation, the gap between the pads and the front brake disc does not require adjustment.

When braking, the brake pads act on a relatively small part of the surface of the brake disc, leaving a large part of it open, which is effectively blown by air.

The result is a very rapid cooling of the brake disc, which ensures high braking efficiency even with frequent braking at high speeds.