To do the job, we need: a bottle of carburetor flushing fluid; suitable hose 0.5 meters; receiver gasket; head and ring key for 13; key for 10; flat and Phillips screwdriver; wires with lugs for connecting to the injector

We work on a cold engine. We relieve the pressure in the power system, the article is “Reducing the fuel pressure of the Niva Chevrolet”.

Disconnect the negative battery terminal with a 10 key.

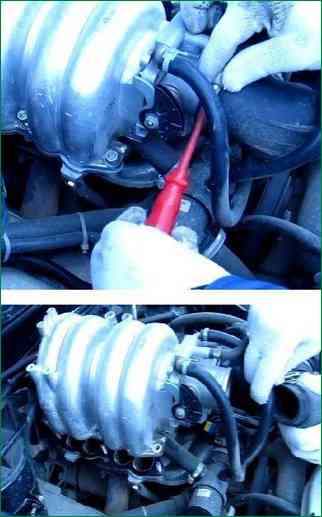

Unscrew the oil filler cap and remove the top engine protection, install the oil filler cap in place, Figure 1.

If flushing of the throttle assembly is not required, then it is better not to remove the throttle assembly so as not to replace the gasket under the throttle assembly.

In a vehicle equipped with a cable-actuated throttle assembly:

- using a screwdriver, disconnect the cable from the throttle drive sector, Figure 2.

- using a 10 wrench, unscrew the two bolts securing the cable bracket to the receiver, Figure 3.

- depressing the lock of the connector of the wiring harness of the engine control system, disconnect the block from the canister purge valve, with a 10 spanner wrench, unscrew the two bolts securing the canister purge valve bracket, Figure 4;

Using a screwdriver, we loosen the clamp of the air supply hose to the throttle assembly and take the hose to the side, Figure 5.

For a vehicle equipped with an electronic throttle control:

Disconnect the wiring harness connector from the throttle assembly, Figure 6.

Using a screwdriver, we loosen the gas supply hose of the crankcase ventilation system and loosen the air supply clamp to the throttle assembly.

Loosen the right clamp for air supply to the throttle assembly and move the hose to the side.

With a head of 13, we unscrew the five nuts securing the receiver to the intake pipe, Figure 9.

Remove the receiver from the studs and set it aside, Figure 10.

Remove the receiver gasket, Figure 11.

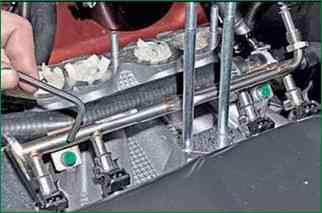

Squeezing the spring retainer of the wiring harness block, disconnect the block from the injector connector, Figure 12.

Similarly, disconnect the wiring harness pads from other injectors and remove the wiring harness from the ramp.

Using a “5” hexagon, unscrew the two screws securing the ramp to the intake pipe.

Using the “17” key, unscrew the fitting of the rail tube, holding the upper end of the fuel supply hose to the rail with the same key by the hexagon, Figure 14.

We pull the ramp along the axes of the injectors and, overcoming the resistance of the rubber sealing rings of the injectors, remove all four injectors from the inlet pipe holes (Fig. 15).

To remove the nozzle with a screwdriver, move the nozzle lock and remove it.

To make it easier to remove the nozzle from the rail, you need to spray the joint of the nozzle with WD-40 penetrating lubricant.

Swinging the nozzle, we take it out of the ramp.

Having prying off with a thin-blade screwdriver, remove the O-rings from the nozzle and atomizer body.

The injector O-rings are the same.

Similarly, we dismantle other nozzles.

We put the nozzles in a suitable container and thoroughly rinse the outer parts of the nozzles from the carburetor and nozzle cleaning can (Fig. 17).

We connect wires with tips and a suitable hose 0.5 meters long to the nozzle (Fig. 18).

Pour the flushing liquid through the funnel connected to the hose.

We connect a hose with a compressed air gun to the hose and, by connecting the ends of the wires to the battery, we clean the injector nozzles (Fig. 19).

Monitoring the quality of the nozzle spray.

If the spray is bad or the nozzle "pouring", then the nozzle needs to be replaced.

We wash and blow through all the openings of the ramp (Fig. 20).

Install

Install all parts in reverse order.

We replace the sealing rings, apply a thin layer of engine oil on them during installation.

Install a new gasket under the receiver.

The tightening torque of the rail mounting screws is 9–13 Nm, and the ramp tube fitting is 20–34 Nm