The vehicle has a 12V electrical system.

Body ground is connected to the negative battery terminal

The battery is located in the engine compartment or under the rear seat (models with air conditioning and some diesel models).

The battery performs three main functions in the car's electrical system:

- – gives electric current to start the engine;

- - stabilizes the voltage in the electrical system;

- - Can provide current for a short time when the power demand exceeds the generator output. Sealed batteries

- - standard for all cars. They do not have filler plugs on the body.

The battery is completely sealed, apart from two small ventilation holes on the side.

These vents allow the resulting gases to escape.

Sealed batteries have the following advantages over conventional batteries:

- – no need to add water for battery life;

- – the battery is protected from overcharging.

If too much voltage is applied to the battery, it will not take as much current as a regular battery.

Increasing the voltage will continue to charge a regular battery, resulting in gassing and loss of electrolyte;

- - the battery can be recharged, like a normal one. This is very important when the car is parked in one place for a long time;

- - with smaller dimensions and weight, the voltage and current strength remained the same. The battery has two indicators:

- - battery capacity indicator is determined at 27 °C. Capacity when fully charged provides 10.5V or more;

- - battery capacity indicator when starting a cold engine is determined by testing at -18 ° C.

Using this test, you can determine the battery power when cranking the crankshaft on a cold engine.

Battery standby power is defined as the maximum possible continuous driving time at night with minimal electrical load without using generator output.

Expressed in minutes, standby power (or E value) is the time required for a fully charged battery at 27°C and a 25A discharge to reach 10.5V at the terminals.

Battery life is limited. However, with proper care, the battery will last for many years.

If the battery tested well, but malfunctions are detected, the following factors may be the cause of the malfunction or failure:

- – some device was left on all night;

- – in short periods the car was moving at low speed;

- - Vehicle electrical load exceeded generator output, often with non-standard equipment included;

- - a malfunction in the charging system

- - slipping of the alternator belt, malfunction of the alternator or voltage regulator, etc.;

- - battery misuse

- - no cleaning, improper fastening of the terminals or loosening of the clamps;

- - mechanical failures of the electrical system

- - shorted or pinched wires. Sealed batteries have a built-in hydrometer used for diagnostics.

A visible "green dot" indicates that the battery is ready for testing.

When the color of the green dot changes to darker, it indicates that the battery is not ready for testing. In this case, it is necessary to check the electrical systems and charging.

A light yellow color means that the liquid level has dropped below the tip of the hydrometer.

Doing so may cause excessive or prolonged charging or deterioration of the battery. If the battery cannot be recharged, replace it.

Removing and installing the battery

Preparing the car and opening the hood

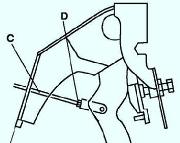

Disconnect the wire terminal from the negative battery terminal

For convenience, we remove the wire from the holder

Using a 10 key, we loosen the nut of the clamping bolt of the terminal and disconnect the terminal from the positive battery terminal

If the 2.0 engine is installed, press the cover latch

And remove the cover of the casing of the electronic control unit

Use a 10 key to unscrew the fastening nuts and remove the pressure plate

After that, remove the battery from the car

Install the battery in reverse order

Set the pressure plate so that the arrows on the plate point forward

Before connecting, we clean the terminals and battery leads and apply a thin layer of conductive grease on them

For protection, we apply a protective varnish to the terminals with installed terminals