Checking the thermal gaps in the Mazda 3 valve drive mechanism

Disconnect the negative battery cable.

Remove the right wheel.

Remove the right mudguard.

Remove the spark plugs.

Disconnect the high voltage wire.

Disconnect the oil control valve (OCV) connector.

Remove the ventilation hose.

Remove the cylinder head cover.

Make sure the engine is cold.

Measure valve clearance.

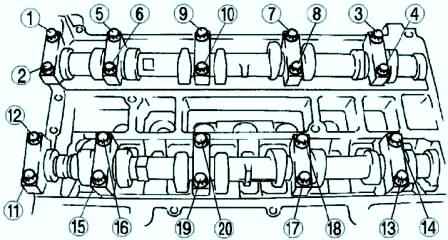

To measure the valve clearance, turn the crankshaft clockwise until the #1 piston is at TDC on the compression stroke.

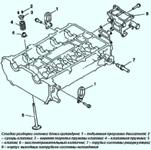

Using a special feeler gauge, measure the valve clearance at point A (fig. 1).

Record the measured values so you can select the appropriate valve lifters if they need to be replaced later.

Rotate the crankshaft 360° clockwise until the #4 piston is at TDC on the compression stroke.

Same as in the first case, measure the valve clearance at point B (see fig. 1).

Standard clearance (engine cold):

- - inlet - 0.22–0.28 mm;

- - release - 0.27–0.33 mm.

If the valve clearances are not correct, adjust them, or, if adjustment is impossible, replace the valve lifters with new ones.

Reinstall all removed parts in the reverse order of removal.

Adjustment of thermal gaps in the valve drive mechanism

Disconnect the negative battery cable.

Remove the right wheel.

Remove the right mudguard.

Remove the spark plugs.

Disconnect the high voltage wire.

Disconnect the oil control valve (OCV) connector.

Remove the ventilation hose.

Remove the cylinder head cover.

Make sure the engine is cold.

Remove the drive belt.

Remove the right joint shaft from the intermediate propeller shaft.

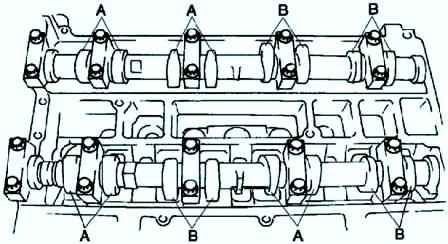

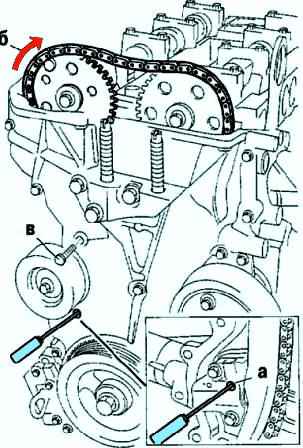

Remove the bottom plug of the engine front cover (fig. 2).

Remove the top plug of the engine front cover.

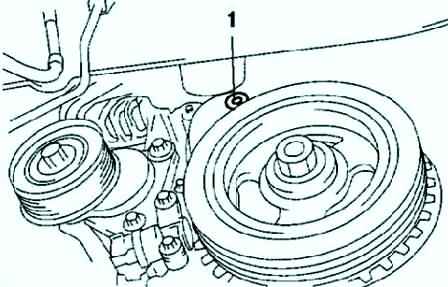

Remove the bottom plug of the cylinder block (fig. 3).

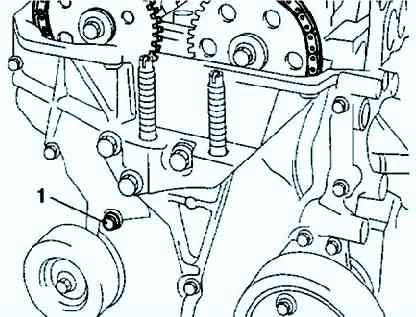

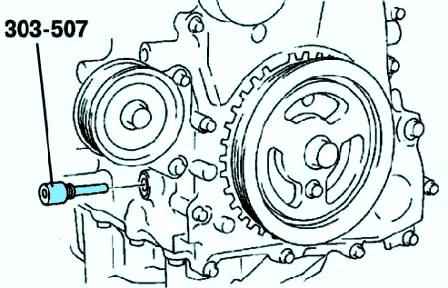

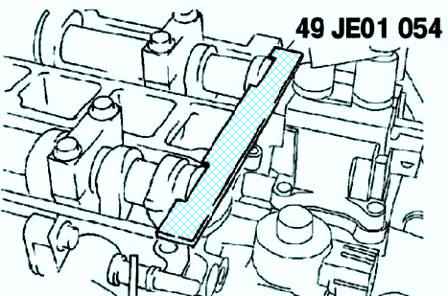

Install the special tool (fig. 4).

Turn the crankshaft clockwise to TDC on cylinder #1.

Loosen the timing chain.

Using a suitable screwdriver or similar tool, unlock the chain tensioner ratchet.

Turn the exhaust camshaft clockwise using the appropriate wrench (hexagon) and loosen the timing chain.

By placing an appropriate bolt (M6 1.0 length 25-35mm) in the hole of the top plug of the engine front cover, fix the chain guide in the loose position (fig. 5).

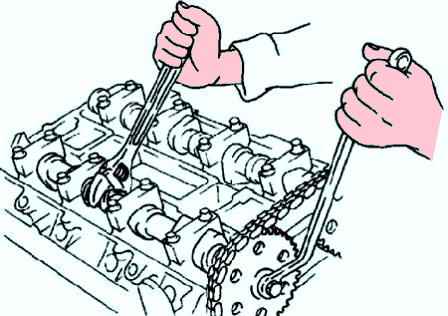

Lock the exhaust camshaft using the appropriate wrench (hexagon) (fig. 6).

Remove the exhaust camshaft sprocket (fig. 7).

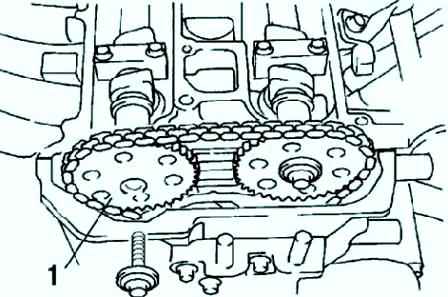

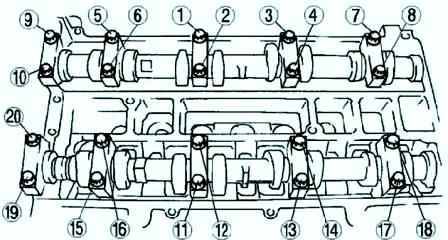

Loosen the camshaft bolts in several steps in the order shown (fig. 8)

Cylinder head and camshaft bearing caps are numbered to make it easier to reinstall them in their original reassembly position.

Once removed, keep the covers together with the cylinder head from which they were removed. Do not mix caps.

Remove the camshaft.

Remove the valve lifter.

Select the appropriate shim according to the following diagram and notes taken during the initial inspection:

- new shim = removed shim + measured valve clearance - standard valve clearance.

- - inlet - 0.25 mm;

- - release - 0.30 mm.

Standard (cold):

- - inlet - 0.22–0.28 mm (0.25±0.03 mm);

- - release - 0.27–0.33 mm (0.30±0.03 mm).

Install the camshaft, the piston of cylinder No. 1 should be in the TDC position.

Tighten the camshaft bolt in two steps (Fig. 9): 5.0-9.0 Nm; torque 14.0–17.0 Nm.

Install the exhaust camshaft sprocket (see Fig. 9).

Do not tighten the camshaft sprocket bolt. First check the opening or closing moment of the valve, then tighten the bolt.

Install the special tool on the camshaft (Fig. 10).

Remove the bolt (M6x1.0, length 25-35mm) from the engine front cover to tension the timing chain.

Turn the crankshaft clockwise to TDC on cylinder #1.

Hold the exhaust camshaft using a suitable wrench (hex key) (see fig. 6).

Tighten the exhaust camshaft sprocket bolt to 69-75 Nm.

Remove the special tool from the camshaft.

Remove the special tool from the bottom plug hole of the unit.

Turn the crankshaft clockwise two turns to TDC.

If the TDC position is not reached, loosen the crankshaft pulley bolt and carry out all operations starting with the installation of the special tool (see Fig. 4).

Apply silicone sealant to the top plug of the front engine cover.

Install the upper plug of the engine front cover, tightening it with a tightening torque of 10 Nm.

Install the bottom plug of the cylinder block, tightening it with a tightening torque of 18–22 Nm.

Install the new engine front cover lower plug, tightening it to 12 Nm.

Install the right intermediate drive shaft and the combined shaft.

Install the drive belt.

Install the cylinder head cover.

Connect the ventilation hose.

Connect the oil control valve (OCV) connector.

Connect the high voltage wire.

Insert the spark plugs.

Install the right mudguard.

Install the right wheel.