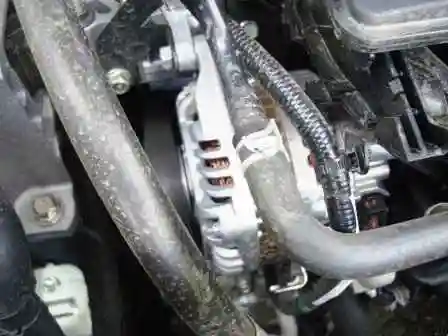

The power supply system consists of a generator, a voltage regulator and a battery.

When these devices work together, power is provided to such consumers of electricity as ignition, headlights, radio, etc.

Alternators are installed on the cars.

When installing additional electrical equipment, make sure that the generator has enough power to power this equipment.

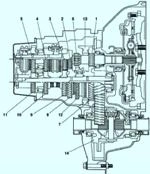

The main elements of the generator are the rotor, stator, rectifier, commutator brushes, electronic voltage regulator, bearings and belt pulley.

The generator is driven by a belt from the crankshaft of the engine.

The generator is a three-phase synchronous electric machine with electromagnetic excitation.

A diode rectifier is built into the generator to convert AC to DC.

The voltage is regulated by the built-in electronic voltage regulator.

When the generator is running, the electric current flowing through the field winding creates a magnetic flux around the rotor poles.

When the rotor rotates, under each tooth of the stator is either the south or the north pole of the rotor; the working magnetic flux passing through the stator teeth varies in magnitude and voltage.

This variable magnetic flux creates an electromotive force in the stator winding.

The wedge shape of the pole pieces of the rotor is chosen in such a way that it makes it possible to obtain the shape of the electromotive force curve close to sinusoidal.

At a high frequency of rotation of the generator rotor, when the voltage of the latter becomes more than 13.6–14.6 V, the voltage regulator is locked, and the current does not pass through the field winding.

The generator voltage drops, the regulator opens and again passes current through the excitation winding.

The higher the frequency of rotation of the generator rotor, the longer the time of the locked state of the regulator, therefore, the more the voltage at the generator output decreases.

The process of locking and unlocking the regulator occurs at a high frequency, so the voltage fluctuations at the generator output are not noticeable and can practically be considered constant, maintained at the level of 13.6–14.6 V.

When checking the generator and operating the vehicle, a number of rules must be observed in order not to disable the generator: - do not allow the generator to operate with the battery disconnected from its clamp.

Without a battery, dangerous overvoltage impulses occur in the vehicle's on-board network when any electricity consumers are disconnected.

They can destroy the electronic equipment of the car, including the voltage regulator and the diodes of the generator rectifier unit;

- do not check the generator's performance "for a spark" even by briefly connecting the "positive" clamp of the generator to the "ground", since in this case a significant current flows through the diodes and they are damaged.

You can only control the generator voltage with a voltmeter;

- the negative terminal of the battery must always be connected to the "mass" of the car, and the positive terminal to the generator clamp.

Incorrect (reverse) switching on of the battery will immediately cause the passage of increased current through the generator diodes, and they will fail;

- do not check diodes with voltages greater than 12 V or with a megger, as it has too high a voltage for diodes, and when checked, they will be broken (a short circuit will occur).

When checking the insulation of the electrical wiring with a megohmmeter, it is necessary to disconnect all wires from the generator;

- it is necessary to disconnect all wires from the generator and the battery when electric welding of any body parts;

- it is necessary to check the circuits and components of electrical equipment and troubleshoot when the engine is off and the battery is disconnected.