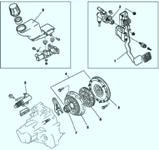

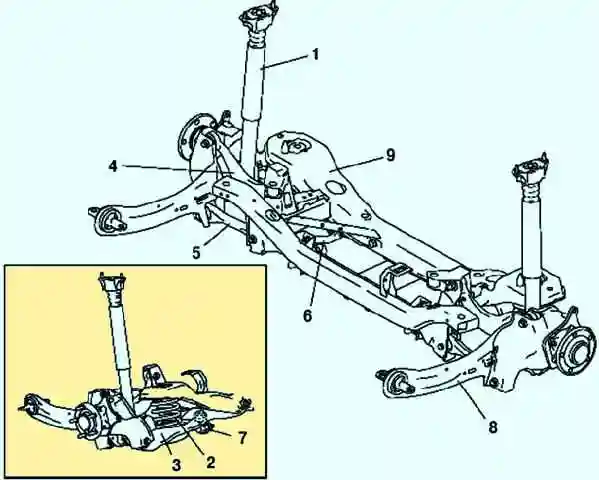

In the rear suspension (Fig. 1) assemblies of struts and leaf springs are used

The upper end of each rack is attached to the car body.

The lower ends of the struts are attached to the axle housing.

The knuckle is held in position by a pair of lower arms on each side, as well as a longitudinal balancer mounted between the body and the knuckle.

Checking Mazda 3 Rear Suspension Parts

We install the car on a lift or a viewing ditch

Inspecting suspension parts

Check the condition of rubber-metal hinges, rubber cushions, condition of suspension springs

Rubber-metal hinges and rubber pads must be replaced in case of ruptures and one-sided bulging of the rubber, as well as when cutting their end surfaces

Not allowed on rubber-metal hinges:

- - signs of aging, cracks;

- - one-sided swelling of the rubber array

Checking the absence of mechanical damage to the suspension elements

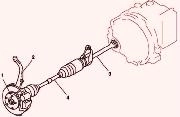

Inspecting the rubber bushings of the upper and lower shock absorber mounts and shock absorbers

Shock absorbers must not drip or sweat

Checking the rubber-metal hinges (silent blocks) of the trailing arms of the rear suspension

Using a mounting spatula, we check for backlash in the internal silent blocks of the rear lower arms and rear fists

Checking the inner and outer silent blocks of the front lower arms

We also check the inner and outer silent blocks of the upper rear suspension arms

Swinging up and down the anti-roll bar, we check for the absence of backlash of the stabilizer strut and the rubber pads of the bar

Checking the springs and compression buffers

Pay attention to the exhaust system. Extraneous knocks emitted by her are often mistaken for a knock in the rear suspension

Possible malfunctions of the rear suspension and solutions

Noise and knocks in the suspension when the car is moving

- shock absorber is faulty

Replace shock absorber

- shock absorber loosening

Tighten the shock absorber mounting bolts

- wear of silent blocks of suspension arms

Replace levers or silent blocks

- spring settling or breakage

Replace the spring

- wheel bearing failure

Replace bearing

Moving the car away from straight ahead

- uneven tire pressure

Set the correct tire pressure

- broken camber

Find the cause of the camber error and adjust the rear wheel alignment

- wheel tires have different wear or tread pattern

Change tires

- settling or breakage of one of the springs

Replace the spring

- deformation of trailing arms

Replace trailing arms

- wear of trailing arm silent blocks

Replace trailing arms

Increased or uneven tire tread wear

- the air pressure in the tires is not correct

Set the correct tire pressure

- wheel settings are violated

Remove wheel misalignment and adjust wheel alignment

- vehicle overload

Do not overload your vehicle

- wheel balance is broken

Balance the wheels