If during the inspection of the beam, breaks or swelling of the rubber of the hinge are revealed, both silent blocks must be replaced

Preparing the car for work.

We install it on a viewing ditch or on a lift. For work, we also need an adjustable stop.

Raise the rear of the car and place stands.

Remove the wheels.

We remove the parking brake cable from the lug of the beam bracket. We install an adjustable stop under the beam lever.

If the car is equipped with an anti-lock braking system (ABS), we remove the rubber clutch of the speed sensor wiring harness from the holder on the lever.

Disconnect the lower shock absorber mount from the beam arm.

We unscrew the nut of the bolt securing the lever to the bracket and the three bolts securing the bracket to the body.

We lower the right side of the beam on an adjustable stop until the fuel tank stops interfering with the release of the lever mounting bolt.

When lowering the beam, make sure that the brake hoses of the rear wheels are not too tight.

Removing the bolt, remove the bracket from the lever.

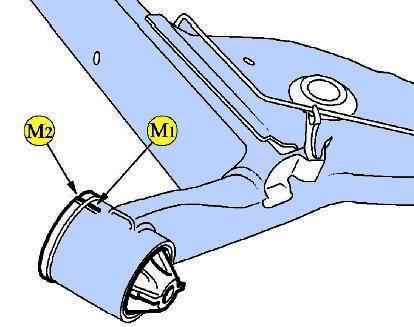

The silent block of the lever perceives a significant part of the loads along the axis of the car, therefore, the rubber massif of the silent block is asymmetrical in cross section.

We note how the silent block was installed relative to the hole in the beam in order to install the new one as well.

It is best to press the silent block out of the lever with a special puller.

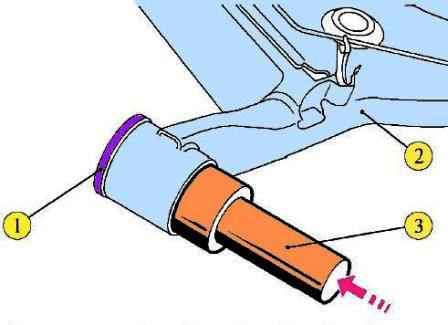

If there is no puller, you can facilitate removal by cutting the outer clip of the silent block.

We insert the hacksaw blade into the hole of the rubber massif of the silent block and saw the plastic outer sleeve of the silent block.

This will significantly reduce the tightness of the silent block in the lever hole.

After that, with a mandrel or a piece of pipe of a suitable diameter, we knock out the silent block from the lever from the side of the threshold, applying force to the outer clip.

Before pressing in a new silent block, we clean the hole in the lever.

Insert the silent block into the hole of the lever, orienting it according to the marks.

We press the silent block into the lever with a cup puller, applying force through the mandrel to the outer sleeve of the silent block (for clarity, we show it on the removed beam).

We replace the silent block of the left lever in the same way, with the exception of the operation of unscrewing the bolts securing the lever bracket to the body (by unscrewing the nut of the bolt securing the left lever to the bracket, remove the bolt and remove the lever from the bracket lug).

Install the rear suspension beam arms in the reverse order.

We finally tighten the nuts of the bolts of the levers to the brackets when the car is on wheels.

Tightening torques for parts:

- - speed sensor mounting bolts 14 Nm;

- - nut of the bolt of the rear suspension arm to the body bracket 125 Nm.