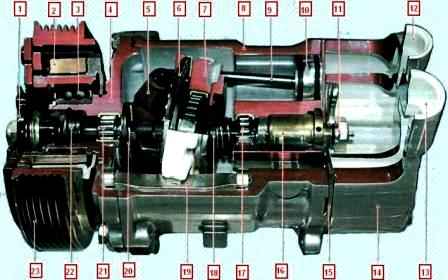

The air conditioning compressor is used to circulate the refrigerant in the system

The compressor shaft is mounted in an aluminum front housing cover on bearings and sealed on the side of the drive pulley with an oil seal

The compressor drive pulley is mounted on a double-row ball bearing and constantly rotates when the engine is running.

When the air conditioner is turned on, the torque is transmitted from the pulley to the compressor shaft through a friction clutch with an electromagnetic drive.

If the system is working, when the air conditioner is turned on, a click is heard - this is the clutch pressure plate, under the action of an electromagnet, engages with the drive pulley, and the compressor rotor starts to rotate.

But during the operation of the air conditioner, the following compressor malfunctions may occur.

If, when the air conditioner is off, the clutch makes extraneous sounds during rotation, heats up or smells of burning, then its bearing has probably begun to collapse.

In this case, the bearing must be replaced.

In some advanced cases, it may be necessary to replace the compressor clutch assembly or its components.

If you don't hear a click after turning on the air conditioner, then the following problems may occur:

- - a refrigerant leak has occurred and the control system is blocking the compressor from turning on;

- - the pressure sensor in the system has failed;

- - malfunctions in the electrical circuits of the control system;

- - the winding of the coil of the clutch electromagnet burned out;

- - the engine control unit for some reason (high engine coolant temperature, high engine speed) has blocked the compressor from turning on.

If the clutch rotates easily and freely, but when the air conditioner is turned on, extraneous noises are clearly audible or the engine even stalls, then the compressor is most likely stuck.

The internal pumping part of the compressor cannot be repaired. In this case, the compressor will have to be replaced.

If a click is heard, the clutch easily rotates the compressor shaft, and there is no coolness in the cabin.

In this case, it only seems that the compressor is working, but in reality it is not pumping anything.

Only an experienced specialist with special control and diagnostic equipment can establish the truth.

The cause of the malfunction can be most accurately determined after a complete diagnosis at a specialized service center for the repair of automotive air conditioners.

Removing the air conditioning compressor

Removing the auxiliary drive belt Replacing drive belts for car components Lada Largus engine K4M

Removing the protection of the power plant

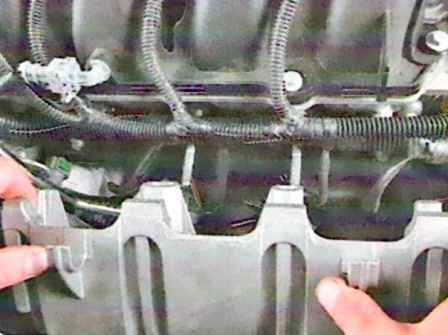

If the car has a 1.6 engine, remove the fuel rail protection

Before disconnecting the pipes of the air conditioning system, we discharge the system, as described in the article - How to unload and for load the refrigerant of the Lada Largus air conditioning system

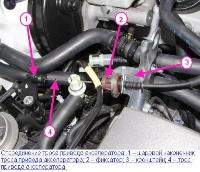

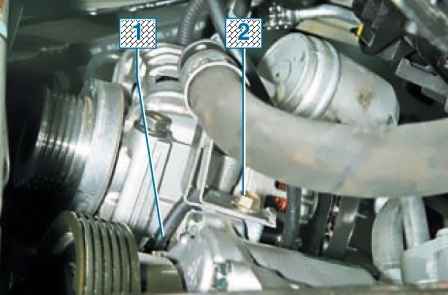

When the system is depleted, it is necessary to release the refrigerant through the valves of the low 1 and high 2 pressure pipes, closed with caps

To release the refrigerant, press the valve stems with a suitable tool

If it is necessary to replace the valve, then with a key similar to the metal cap of the wheel valve, we unscrew the valve from the tube fitting

After that, with a 10 head, unscrew the two bolts

And disconnect the high and low pressure pipes from the compressor cover

We close the openings of the compressor and tubes with suitable plugs

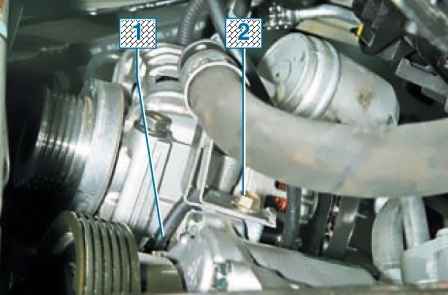

On a car with a 1.6 engine, disconnect the tip of the wire 1 from the outlet of the electromagnetic clutch of the compressor and unscrew the bolt 2 of the high-pressure hose bracket by 10

The difference in removing the air conditioning compressor on a car with a 1.6 engine is a slightly different location of the output of the electromagnetic clutch

With a 13 head, we unscrew the four compressor mounting bolts

And remove the compressor

Compressor installation

We combine the holes in the ears of the compressor 1, and in the bracket and install four bolts 2 of the compressor 1 into the holes. The tightening torque of the compressor mounting bolts is 21 Nm

We remove the plugs from compressor 3, and tubes 1 and 2. Before installing the tubes, you need to install new o-rings.

We apply compressor oil to the sealing rings and attach the tubes to the compressor. Tightening torque Tubing - 8 Nm

After that, install the accessory drive belt

Connect the plug-in block of the electromagnetic clutch to the car wiring harness

We evacuate the air conditioning system and load R134a refrigerant in the amount of 475±35 g.

We check the system for leaks and check the performance of the air conditioning system.

When buying a new compressor, you need to clarify how much oil is poured into the compressor in order to fill in the required amount when refueling the air conditioner.