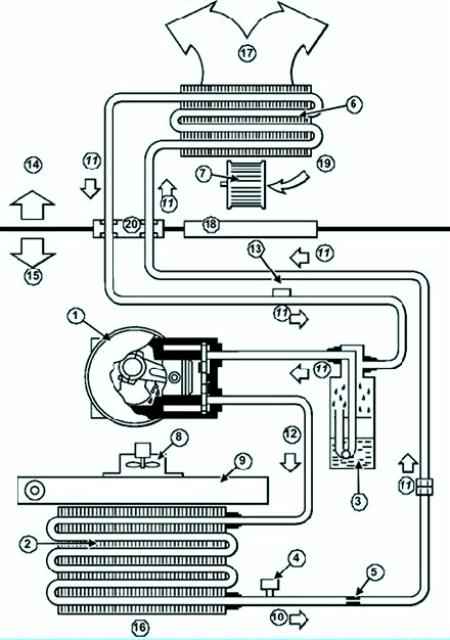

Your vehicle's air conditioning system must be charged with HFC-134a (R-134a) refrigerant or a similar operating fluid that is fully equivalent to that specified in its properties

Using a different refrigerant will cause severe damage to the air conditioning system and will require a complete replacement of the system

It is not recommended to release the refrigerant into the atmosphere.

The HFC-134a (R-134a) refrigerant used in Mazda vehicles does not have a harmful effect on the ozone layer of the atmosphere.

However, the release of refrigerant into the atmosphere may contribute to global warming to a small extent.

General recommendations for air conditioner operation

Clear snow and ice from the wiper blades and the air intake grille located in front of the lower edge of the windshield. This will increase the efficiency of the heating system.

When the ambient temperature is low and the engine is cold, air may not enter the passenger compartment through the lower air ducts for 150 seconds (maximum). This is not a malfunction.

After the engine has warmed up sufficiently, warm air will begin to flow normally through the bottom vents.

Keep all windows and sunroof closed when operating the air conditioner.

After parking the car in the sun, drive for two to three minutes with the windows open in order to quickly remove hot air from the passenger compartment.

Next, close the windows so that the air conditioner can cool the air in the cabin faster.

The air conditioner should be switched on at least once a month and run for approximately 10 minutes. This will prevent the failure of the air conditioner due to lack of lubrication.

If the coolant temperature gauge reaches the "Hot" (high temperature) mark, turn off the air conditioner.

If the coolant temperature rises significantly, the air conditioner will turn off automatically.

This can happen, for example, when the engine is idling for a long time on a hot day.

Refrigerant

Refrigerant specifications are listed on a label located in the vehicle's engine compartment.

Use the filling station's high pressure line to collect, create a vacuum and charge the R134A refrigerant.

Be sure to plug the openings of the air conditioning piping with plugs to prevent moisture from entering the system.

Remove plugs from spare parts only at the last moment before installing them.

With the engine running, check for leaks with a leak detector five minutes after refueling; at the same time, the heater and the air blower must operate at maximum mode.

Follow all oil topping instructions exactly when working on air conditioning components.

When replacing valves, observe the required tightening torque of 8 Nm.

Air conditioning system maintenance

Each year of operation it is recommended:

- - clean and purge the condenser and radiator of the engine cooling system;

- - make sure that the condensate drain in the cold air blower is not clogged.

Checking the refrigerant charge of the refrigeration circuit or draining the refrigerant is recommended every four years.

Bactericidal preparation for the treatment of the air conditioning system

Treat the heating and ventilation system with a special preparation after each winter season or a long break in the system to eliminate possible contamination.

Spray all of the product from the aerosol can with extension through the filter nozzle of the cabin ventilation system.

It is strictly forbidden to spray the product through the air intake inlet due to the risk of damage to the electric air blower. Please wait 15 minutes

Turn on the fan at a very low speed for 5 minutes.

Refrigerant drain

Because the air conditioning circuit is equipped with only one filling valve, some filling stations use only the high pressure pipe.

In some cases, let the system run for a few minutes before draining the refrigerant to ensure complete draining.

When draining the refrigerant or checking the charge of the refrigeration circuit, three cases must be taken into account:

- 1. Engine and A/C running;

- 2. The engine runs, but the air conditioner does not work;

- 3. The engine and air conditioner do not work.

Engine and A/C running

Let the air conditioner run up to two times turn on the engine cooling fan, then stop the engine.

Perform the first drain of the refrigerant (measure its drained amount), wait 15 minutes.

Check if relative pressure is less than or equal to 0 bar, restart drain cycles if pressure is not less than or equal to 0 bar.

Sum the amount of refrigerant drained from all cycles.

Charging is considered sufficient if the amount received is +35 gr. or -100 gr. from the nominal value.

The engine is running, but the air conditioner is not working

Let the engine run until the cooling fan turns on twice, then stop the engine.

Perform the first drain of the refrigerant (measure its drained amount), wait 15 minutes.

Let the engine run until the electric fan of the cooling system turns on twice, drain the coolant a second time (measure its drained amount).

Restart drain cycles if pressure is not less than or equal to 0 bar.

Sum the amounts of refrigerant drained from all cycles.

Charging is considered sufficient if the amount received is +35g or -100g from the nominal value.

Engine and A/C not working

Perform the first refrigerant drain. Engine and A/C not running.), wait 2 hours. Restart the drain cycles if the pressure is not less than or equal to 0 bar.

Sum the amounts of refrigerant drained from all cycles.

Charging is considered sufficient if the amount received is +35 gr. or -100 gr. from the nominal value.

Pull out air

Be sure to properly evacuate the air from the refrigeration circuit before charging it with refrigerant, otherwise the air conditioner will fail.

There are two cases to consider:

- – air is pumped out immediately after the circuit is discharged;

- – air is pumped out a few hours or days after the circuit is discharged.

The air is evacuated immediately after the circuit is discharged.

The air is pumped out for 20 minutes. Air is evacuated a few hours or days after the circuit is discharged.

The air is pumped out for 45 minutes to completely eliminate traces of moisture.

After evacuating air, perform a leak test on the circuit (some charging stations do this automatically).

Charging refrigerant

Add the correct brand and quantity of oil, depending on the work performed.

Refill.

Empty the filling station pipes.

Check if the system is working. Search for leaks

Search for leaks

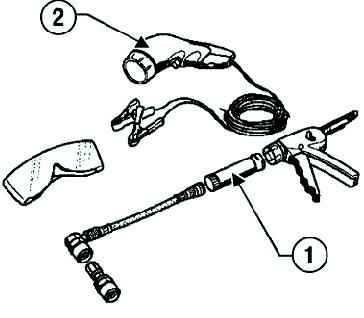

Leaks are detected using a contrast agent supplied in single-use capsules, and traces of leaks are detected using an ultraviolet lamp (Fig. 3).

The contrast agent remains in the air conditioning system.

Using an ultraviolet lamp, you can check the condition of the refrigeration circuit.

If there are characteristic fluorescent traces, it is forbidden to inject a contrast agent into the refrigeration circuit.

Inject a dose of contrast agent if there are no characteristic fluorescent traces and a warning label (about the use of contrast agent in the past).

Introduction of a contrast agent into the contour

Install the contrast medium injection system on the low pressure valve, on vehicles with a single valve. Inject the contrast agent into the circuit.

Turn on the air conditioner and let it run for approximately 15 minutes.

Leak Detection Procedure

Perform a preliminary check (with the engine off) by running a UV lamp over the refrigeration circuit.

If there are no leaks revealed:

- – carefully clean the external surfaces of the parts of the refrigeration circuit,

- - turn on the air conditioning compressor and do not turn it off until the location of the refrigerant leak is determined (if unsuccessful, check the condition of the evaporator).

After using a contrast agent, be sure to indicate on the warning label (supplied with the contrast agent capsule) the fact of its use and the date of the operation.

The label must be affixed in a visible place near the filling valves of the refrigeration circuit (on the shock absorber support cup).