Prepare the car for the job. Disconnect the negative cable from the battery

Disassemble the passenger compartment to remove the windshield glass:

- - using a 13 wrench and a Torx T20 screwdriver, remove the wiper arms, unscrew the screws securing the windscreen frame linings, remove the linings;

- - use a flat screwdriver to remove the upholstery of the pillars of the wind window;

- - remove the interior rearview mirror;

- - use a Phillips screwdriver to unscrew two screws each and remove the sun visors with holders;

Disassemble the passenger compartment to remove the side windows:

- - recline the back of the rear seat;

- - remove the facings of the bolts of the upper fastening of the rear side seat belts, unscrew the bolts with a head of 17;

- - use a Torx T20 screwdriver and a flathead screwdriver to remove the rear pillar trims.

For the left loading door, remove the wiper arm.

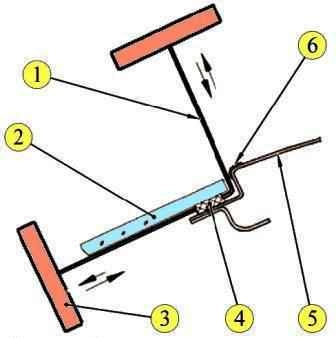

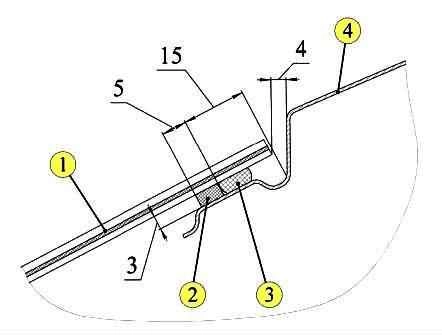

Protect the paintwork of the body in the area adjacent to the glass from damage when cutting the adhesive seam, as shown in Figure 1 (adhesive tape).

Remove

Puncture the glue line and pass a twisted wire saw into the pierced hole, cut the glue line or cut the glue line with a vibroelectro (pneumatic) knife with a long cutting part of 45-55 mm (technological firmware, twisted wire saw TU 64-1-749-80 or holder ZEPK 05 according to Henkel's catalogue, or vibro-pneumatic knife type USAG, Italy, or vibro-electronic knife type FEIN model 53602, Germany).

Remove the glass from the opening (holders - suction cups).

Operations for cutting the adhesive line and removing the glass should be performed with an assistant.

Installation

Prepare the surfaces to be glued (the technological sequence of operations for surface preparation is shown on the example of the Terozon adhesive system).

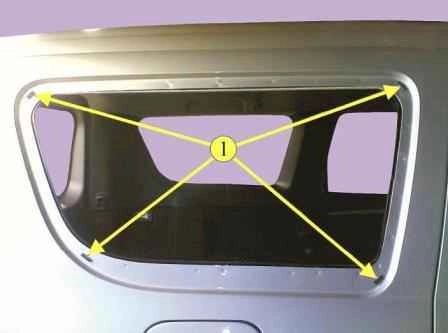

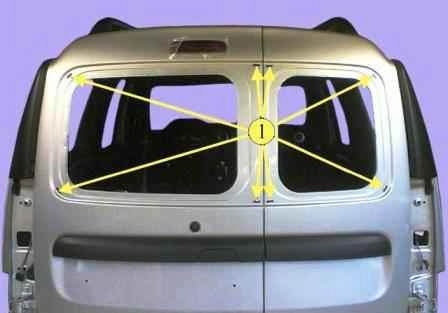

Check the size of the gaps around the perimeter of the fit of the windshield to the frame of the windshield. The check should be carried out with the help of windscreen technology.

The size of the gaps should be no more than 2 mm (a set of probes). If necessary, edit the window opening (a set of straightening tools).

Put the removed or new glass with the help of suction cup holders on the working table with the outer surface down (table type BS-152 coated with felt or linoleum).

Evenly cut off the remaining adhesive seam on the window frame and the removed glass, leaving a layer 1-2 mm thick (technological knife or vibroelectro (pneumatic) knife with a shortened length of the cutting part of the knife (16-18 mm).

If, during the process of cutting glass, sections of the window opening appear that are open to the metal, degrease these areas, then apply primer to the degreased surfaces. Allow the soil to dry for 15 minutes under natural conditions (white spirit, cleaning rags, primary soil, brush).

Apply enamel primer (from the glue system delivery kit) to the primed edges of the window opening, avoiding the primer to get on the remains of the old glue and on the front surfaces of the body.

Dry the applied primer for at least three minutes in natural conditions.

Degrease the layer of old adhesive with isopropyl alcohol.

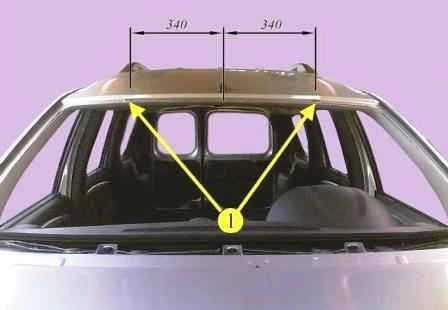

In order to ensure the required thickness of the adhesive seam, in the places indicated in Figures 5, 6, 8,10, install distance spacers with a thickness of: for the windshield and glass of the loading doors - 3 + 1 mm; for side windows – 6+1 mm.

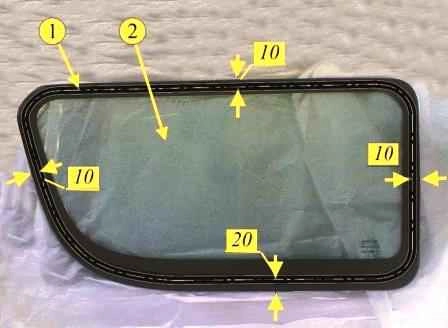

In case of installing new glass, treat the perimeter of the glass with a cleaner (from the adhesive system supplied) or isopropyl alcohol, then apply a glass primer (from the adhesive system supplied) along the edge of the glass with a strip 18-20 mm wide at the place where the adhesive is applied in in accordance with the diagrams shown in figures 7, 9, 11, 12.

After applying the primer, dry the coating for at least three minutes in natural conditions.

Degrease the edge of the edging adjacent to the adhesive seam and install the edging on the lower end of the windshield, ensuring that the edging fits snugly against the glass (white spirit or degreaser from the delivery set).

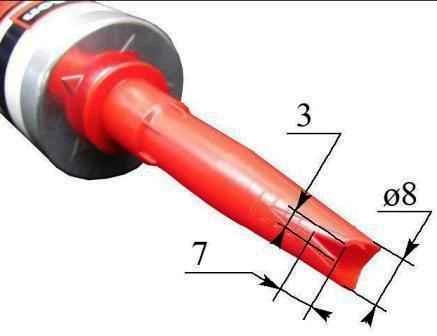

Puncture the exit hole in the tube, put on the tube the tip supplied in the kit (technological firmware).

If the tip of the glue tube requires preparation, then prepare it for work, as shown about in Figure 2 (technological knife, ruler).

Install the tube with glue in the syringe gun.

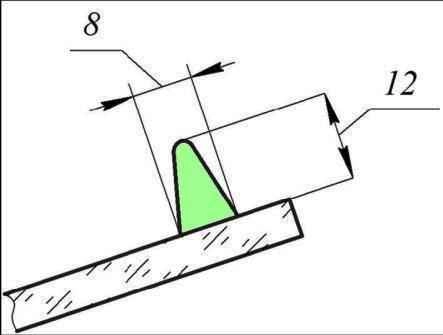

Apply the adhesive to the glass with a uniform, continuous bead of a triangular cross section, as shown in Figure 3, over the applied primer (metal ruler, syringe gun, adhesive from the Monopac Evolution, S-P Kit, Bipac Evolution glass bonding kit or Terostat UHV adhesive) /M”, or “Betasil 1701”).

It is allowed to apply glue on the window opening flange.

Consumption rate of glue for one car: for a wind window - 400 ml; for glass of the left loading door - 150 ml, for glass of the right loading door - 100 ml; for side glass - 150 ml.

Make sure that the holders, Figure 4, are securely fastened to the glass.

Install the glass on the window opening, ensuring a uniform gap around the perimeter between the end of the glass and the body.

The maximum allowable holding time of the applied adhesive before installing the glass on the body is 15…20 minutes.

Evenly and carefully press the glass against the opening, ensuring even crushing of the adhesive bead.

Warning:

- - it is forbidden to mix materials of different adhesive systems;

- - it is forbidden to use materials after the expiration date;

- - reducing the thickness of the adhesive between the glass and the body, less than specified, is unacceptable, as this leads to a glass crack in operation;

- - the presence of glue on the front surfaces of the body and glass is not allowed. If necessary, remove excess glue (rags, white spirit);

- - perform glass installation operations with an assistant;

- -optimal adhesive polymerization mode: air temperature 23°C, humidity 50%, at low temperature and humidity, the adhesive polymerization time increases.

To prevent the glass from sliding down, fix it with three pieces of adhesive tape to the body with a length of 250 - 300 mm.

To prevent the glass from moving, it is forbidden to move the car and close the doors abruptly within 7-8 hours after installing the windows.

Keep the sliding windows of the doors open so that when closing the doors there is no air pressure on the glass.

Work related to the application of force to the glass can be started 14 hours after gluing.

The optimum strength of the adhesive bond is achieved, depending on weather conditions, after 4-6 days.

Check the car for leaks.

To do this, it is necessary to shed the adhesive seam of the installed glass with a jet of water (hose washer).

Leakage along the glue line is not allowed.

Install upholstery, trim and other parts removed from the vehicle in the reverse order of removal.

Clean the glass on both sides (rags, isopropyl alcohol or cleaner supplied).