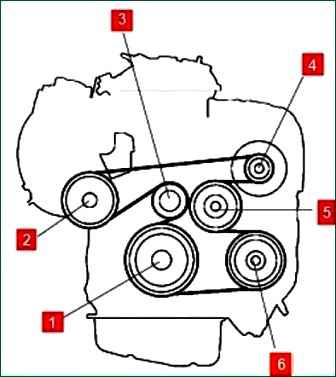

Engine accessories are driven by a single multi-ribbed belt.

This reduces the overall length, weight and number of engine parts

Automatic tensioner eliminates the need to adjust belt tension

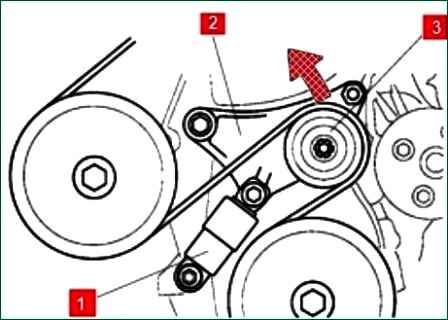

The automatic belt tensioner consists of a tensioning pulley, a lever and a tensioner

The idler pulley maintains the belt tension under the force of the spring, which is located in the tensioner

One of two types of mechanism can be used on a car, although their principles of operation are the same and they are interchangeable

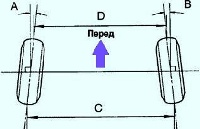

The tension of the accessory drive belt is checked in the area between the pulleys of the generator and the power steering pump

A correctly tensioned belt should rotate 90º from the force of the fingers 15-20 N (1.5-2 kgf)

If the belt is loose, the tensioner must be replaced

When inspecting the belt, it must be replaced if tears, abrasions and cord exposure are found.

The presence of cracks on the inner ribs of the belt is considered acceptable, with the exception of the absence of fragments of the ribs

The figure shows the layout of the belt

In order to remove the belt, you need to loosen the belt tensioner using the socket by 19 by turning the key clockwise

Remove the belt and install it according to the diagram

After installation, we check the correct location of the belt ribs in the pulley streams. In case of displacement, reinstall the belt

Checking the technical suitability of the belt according to the maintenance schedule is required every 20 thousand kilometers of the vehicle.