Check the timing belt tension at every maintenance

If necessary, adjust the tension, since when the belt is loose, its teeth wear out quickly and, in addition, the belt may jump on the toothed pulleys of the crankshaft and camshaft, which will lead to a violation of the valve timing and loss of engine power, and with a significant jump - to its accidental damage.

The manufacturer recommends checking the belt tension and monitoring it during adjustment using a special strain gauge tester.

In this regard, there is no data on the amount of force when bending a belt branch by a certain size in the technical documentation.

In practice, you can initially approximately estimate the correctness of the belt tension according to the “rule of thumb”: press on the belt branch with your thumb and determine the deflection with a ruler.

According to this universal rule, if the distance between the centers of the pulleys is between 180 and 280 mm, the deflection should be approximately 6 mm.

There is another way to pre-check the belt tension by twisting its leading branch along the axis. If the branch can be twisted more than 90° by hand, the belt is loose.

These methods can only diagnose excessive belt loosening, so contact the service to accurately check and adjust the tension.

Replace the timing belt if, upon inspection, you find:

- - traces of oil on any surface of the belt;

- - signs of wear of the serrated surface, cracks, undercuts, folds and delamination of the fabric from the rubber;

- - cracks, folds, depressions or bulges on the outer surface of the belt,

- - loosening or delamination on the end surfaces of the belt.

Be sure to replace a belt with traces of engine oil on any surface, as oil quickly destroys rubber.

Remove the cause of oil getting on the belt (usually a leak in the seals of the crankshaft and camshafts) immediately.

Work on a viewing ditch, overpass or, if possible, on a lift.

Set the piston of the first cylinder to the TDC of the compression stroke and remove the auxiliary drive pulley and the lower cover of the timing belt

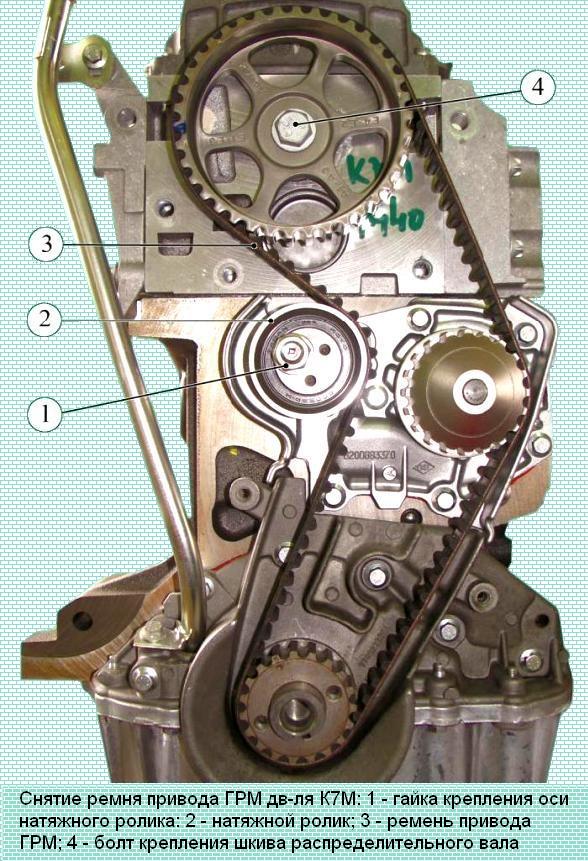

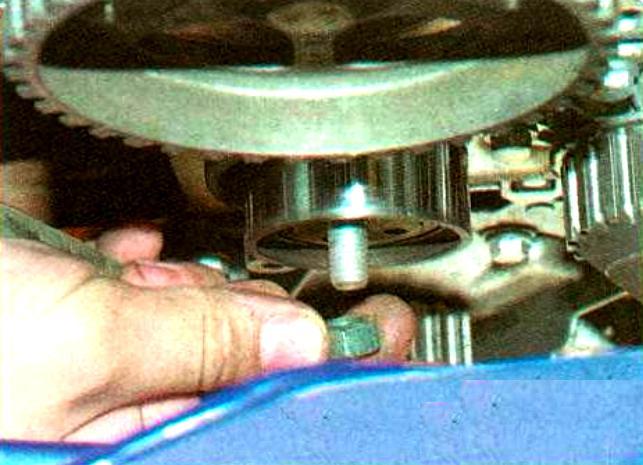

We remember or mark in any way the position of the tension roller relative to the axis, loosen the tightening of the roller fastening nut

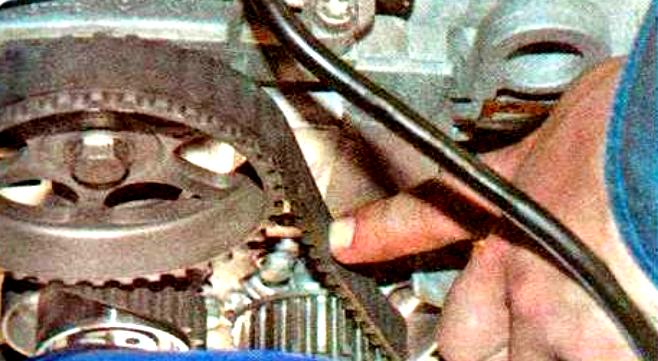

Turn the roller clockwise, thereby loosening the tension of the timing belt

Remove the belt from the toothed pulley of the water pump

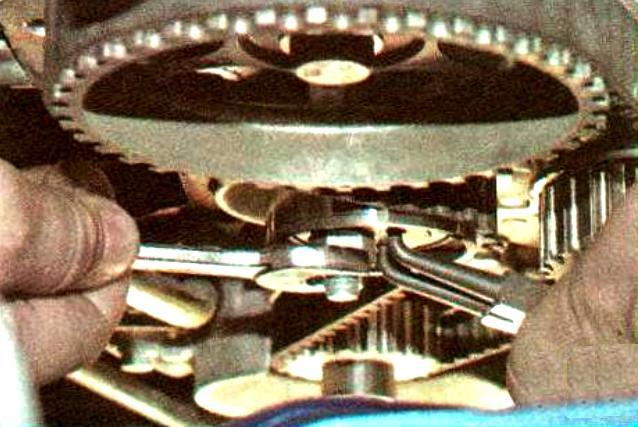

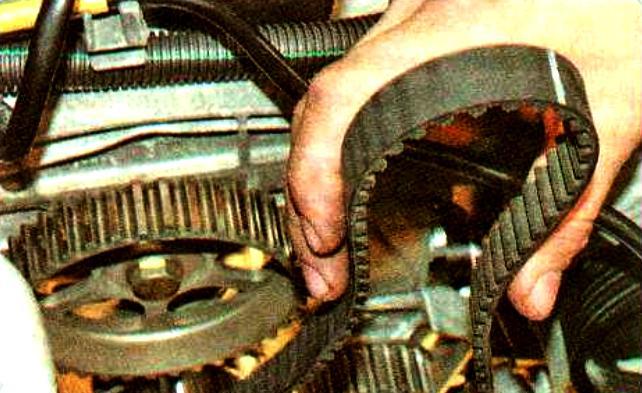

Remove the belt from the camshaft

Remove the belt from the crankshaft

And remove the belt completely

The original belt must be marked with arrows indicating the direction of its movement when the engine is running.

If there are no such arrows on the belt, then you need to apply them with paint or a felt-tip pen to set the belt in its original position.

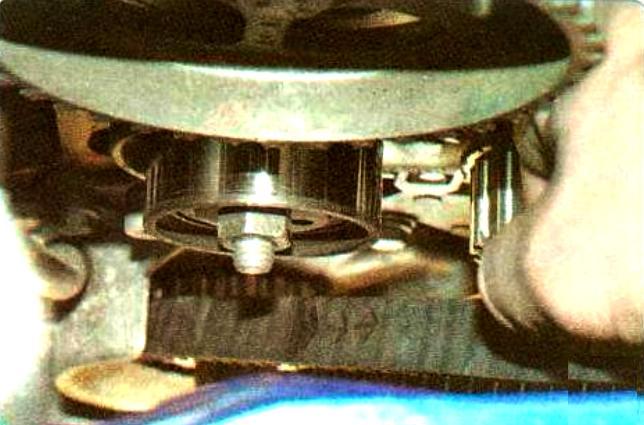

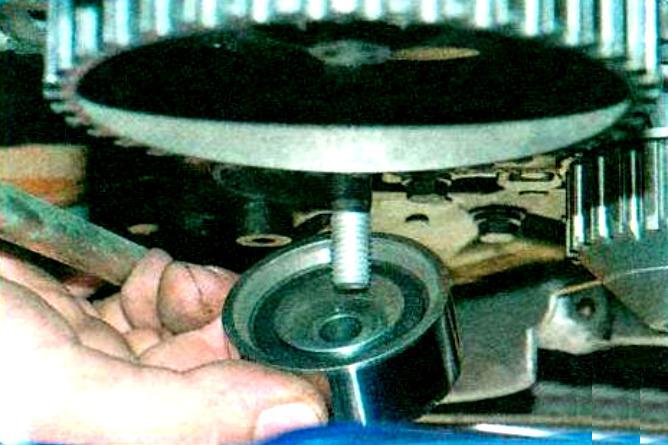

To replace the tension roller, finally unscrew the nut from its axis

Shooting a video

Install the new tension roller in reverse order. In this case, the holes for a special key should be directed outward.

Installing the belt

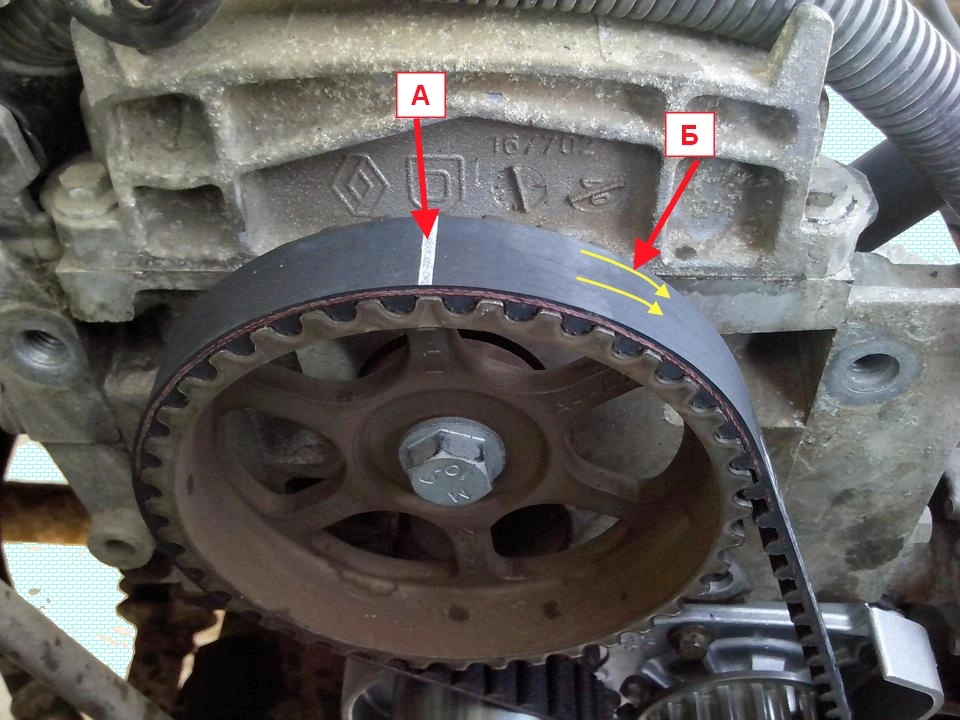

We install the belt first on the camshaft pulley, orienting it with the arrows "B" in the direction of movement when the engine is running and aligning the risk "A" with the alignment mark on the pulley.

Then we pull the leading branch onto the water pump pulley

And the crankshaft pulley, also aligning the notch on the belt with the alignment mark on the pulley. After that, install the belt on the tension roller.

We tighten the belt by turning the tension roller counterclockwise until the marks made earlier coincide, and tighten the roller fastening nut.

We install the accessory drive pulley on the crankshaft and turn the crankshaft by the fastening bolt two turns and check the correctness of the marks. After that, we collect all the details in the reverse order.