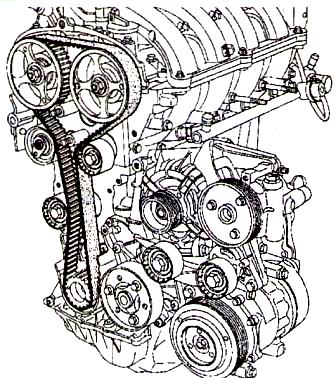

Replacing the timing belt on a Renault Megan car is recommended by the factory after a run of 60,000 km

The method for replacing the timing belt is determined by the type of keyed connection at the end of the crankshaft

The connection can be with or without a key.

Setting the valve timing when installing a toothed pulley with a key

Replacing the timing belt

To replace the belt, we put the car on a lift.

We carry out preliminary work the same as when installing a belt with pulleys without a key.

Disconnecting the battery

Remove the right front wheel

Remove the right front fender liner

The fender liner consists of two parts.

Only the front part needs to be removed. It is screwed with two self-tapping screws and 5 clips

Using a 13 key, unscrew the four nuts securing the amplifier and remove it

Using the 16 key, turn the auxiliary drive belt tensioner and remove the belt (see the article Replacing the accessory belt Renault Megan 2)

We unscrew the bolt securing the pulley for the drive of additional devices.

In order to unscrew the bolt, you need to block the crankshaft from turning.

To do this, the assistant must shift the manual transmission to the highest gear, press the brake pedal and apply the parking brake.

If at the same time it is not possible to unscrew the pulley mounting bolt due to crankshaft rotation, then the shaft must be locked.

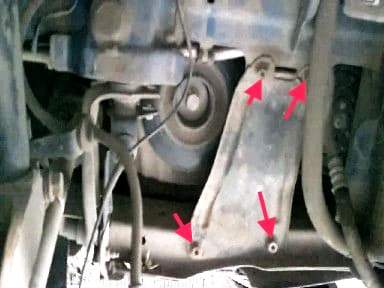

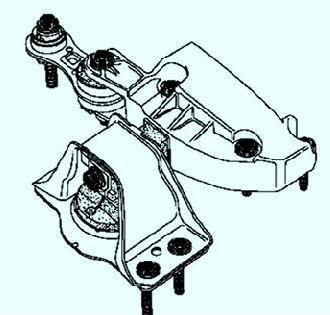

Jacking or hanging the engine by the eye.

Remove the pendulum suspension support

To remove the support, you need to raise and lower the engine, otherwise the air conditioning tube interferes

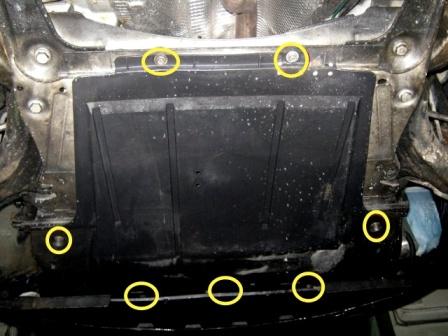

Remove the plastic protective covers, remove the crankcase protection

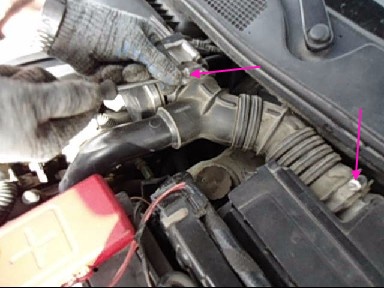

Remove the air filter duct

Remove the throttle assembly (see the article - " How to remove and clean the Renault Megan-2 throttle assembly")

Pry off with a thin blade and take out the plugs of the camshafts.

The plugs are covers made of thin aluminum coated with rubber. There are rubber rounds in the middle of the plugs.

You can remove these plugs and through the hole formed, pry off and take out the plugs with a slotted screwdriver.

But in this case, you will have to select rubber plugs of the appropriate diameter and close these holes

In order not to disturb the valve timing, before removing the F4R timing belt, it is necessary to set the crankshaft and camshafts to the TDC position (top dead center of the compression stroke of the 1st cylinder).

To rotate the crankshaft, we install the bolt securing the auxiliary drive pulley in place by installing a spacer (sleeve or set of washers) between the bolt and the end face.

The crankshaft can also be rotated by turning the front right wheel installed in place in a clockwise direction with the highest gear engaged in the manual transmission.

In order to facilitate turning the shaft, we turn out the spark plugs.

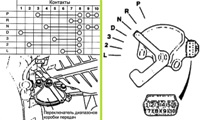

In the TDC position, fix tool Mot.1496 on the ends of the camshafts. (If there is no fixture, then it can be made from a metal plate 5 mm thick according to the drawing).

Unscrew the plug from the hole in the cylinder block. It is located to the right of the oil dipstick.

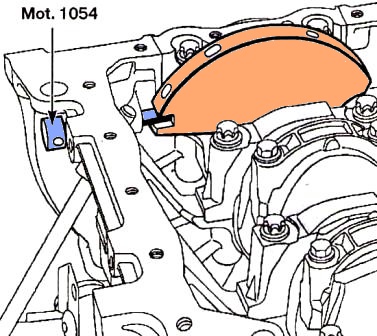

We insert tool Mot.1054, which should fix the crankshaft in the TDC position of the first cylinder.

If there is no fixture, you can use a bolt or rod with a diameter of 8 mm and a length of at least 70 mm.

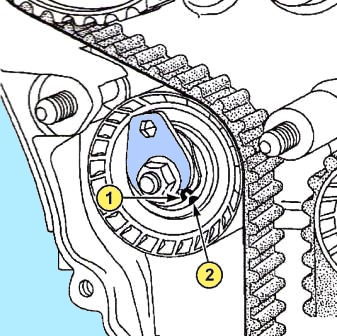

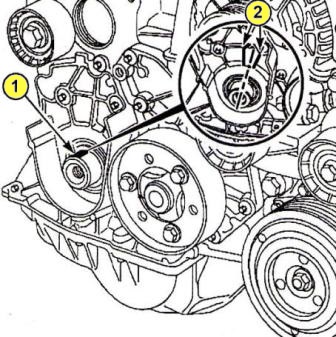

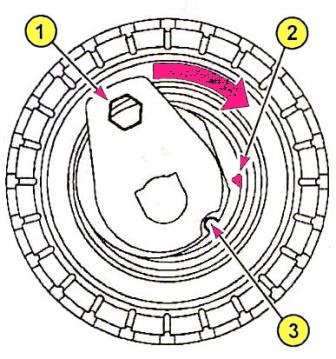

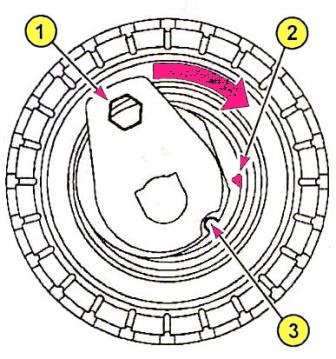

The groove of the crankshaft (1) must be between the two ribs (2).

Install the new idler pulley by correctly inserting the lug (1) of the pulley into the groove (2)

Install the crankshaft sprocket with integral key.

Install new belt and new idler(s)

Tighten the bypass roller bolts to the recommended torque

Belt tension

Do not turn the idler counterclockwise.

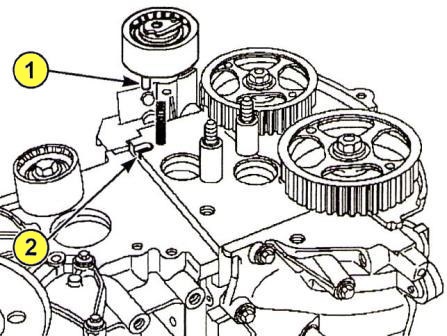

Align the marks (2) and (3) on the idler pulley by inserting a 6 mm Allen wrench in pos. 1

Tighten the tension roller axle nut to 7 Nm

If the camshaft gears were removed (for example, when repairing the cylinder head), then you need to install them and do the following:

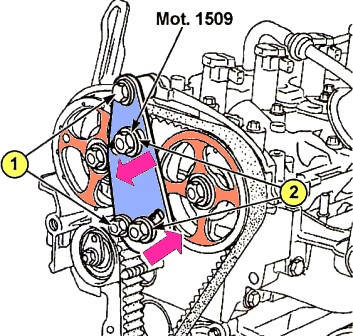

Install tool Mot.1509 to lock the camshaft pulleys.

Tighten the bolt and collar nut(1).

Insert the gear nuts until they come into contact with the camshaft pulleys.

Tighten the nuts (2) securing the gears to 80 Nm.

Tighten the old nuts of the intake and exhaust camshaft pulleys to 30 Nm.

Mark with a pencil between the camshaft pulleys and the cylinder head cover.

Remove camshaft locking tool Mot.1496 and camshaft pulley locking tool Mot.1509.

Turn the crankshaft two turns clockwise as viewed from the drive end.

Checking the timing belt tension

Before completing the second revolution (that is, half a tooth short of the marks made earlier), install the TDC retainer Mot1054 between the balance hole and the crankshaft lock hole.

Lock the timing gear in the valve timing position

Make sure that the tension roller marks are aligned, otherwise, repeat the belt tension adjustment in the following order:

Install tool Mot1496 to lock the camshafts.

Install tool Mot1509 to lock the camshaft pulleys.

Tighten the bolt and collar nut (1).

Insert the gear nuts until they come into contact with the camshaft pulleys.

Tighten the gear nuts (2) to 80 Nm.

Remove the old nuts securing the toothed pulleys of the intake and exhaust camshafts.

Remove tool Mot1509 to lock the camshaft pulleys.

Align the marks (2) and (3) by loosening the idler shaft fixing nut no more than one turn while holding the roller with a 6 mm hex wrench at point (1).

Finally tighten the tension roller nut.

Install tool Mot1509 to lock the camshaft pulleys.

Tighten the bolt and collar nut (1).

Insert the gear nuts until they come into contact with the camshaft pulleys.

Tighten the gear nuts (2) to 80 Nm.

Remove the old intake and exhaust camshaft sprocket nuts.

Install new nuts on the camshaft pulleys.

Tighten the intake and exhaust camshaft sprocket nuts to the required torque.

Remove the tool for locking camshafts Mot1496.

Tighten the nuts securing the toothed pulleys of the intake and exhaust camshafts to the required angle.

Remove TDC tool Mot1054 and camshaft pulley locker Mot1509.

Turn the crankshaft two turns clockwise as viewed from the drive end.

Checking the valve timing

Before checking the installation of the valve timing, make sure that the marks (1) and (2) of the tension roller are aligned

Install TDC lock Mot.1054. Make sure that the marks made earlier on the camshaft pulleys are aligned

Offset grooves should be pointing down and set to a horizontal position

Install (without forcing) camshaft locking tool Mot1496

If the tool cannot be installed, it is necessary to re-install the valve timing and adjust the tension of the timing belt.

The article seems to be difficult to understand, but if you read it several times and do everything consistently, there is nothing complicated.