Regardless of the lifting equipment used, do not use the suspension arm as a support

Removing the lever

Put the car on a two-post lift.

Unlock the steering wheel.

Remove the front wheel and side fender liner.

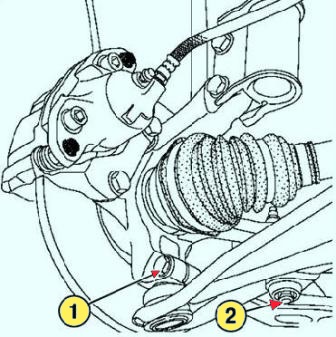

Remove the suspension arm ball joint bolt and the anti-roll bar end ball joint pin nut (Fig. 1).

Press out the tie rod end ball joint using tool (Tav. 476).

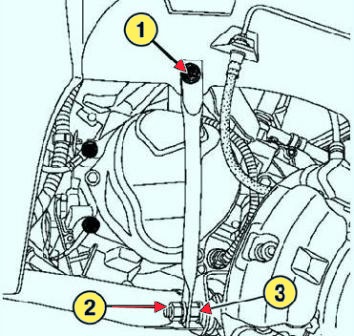

Remove the upper bolt securing the connecting rod between the subframe and side member.

Remove the lower nut of the subframe connecting rod and the bolts of the rear and front suspension arm mountings (fig. 2).

Remove the suspension arm.

Installing the suspension arm

Installation is performed in the reverse order of removal.

Be sure to replace the suspension arm mounting bolts.

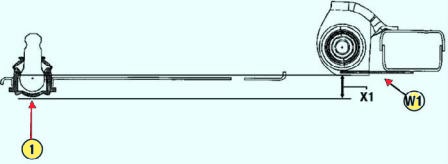

When installing, to avoid tension when tightening silent blocks, set the suspension arm so that the center distance X1 = 24 mm between the lower part of the ball joint of the arm and the lower part of the subframe at the level of the hole in the center of the arm W1 (Fig. 3).

Place a hydraulic jack under the subframe in the area of the middle hole of the suspension arm W1 and raise it until it comes into contact with the subframe.

Lower the hydraulic jack by dimension X1 = 24 mm.

Place the ball joint plug on the hydraulic jack without changing the position of the control arm.

In this position, torque tighten the front and rear suspension arm to subframe bolts to 105 Nm.

Remove the hydraulic jack.

Insert the ball joint into the steering knuckle.

Install and tighten to the required torque:

- - the nut of the lower fastening of the connecting rod of the subframe (62 Nm);

- - bolt of the upper fastening of the connecting rod of the subframe (210 Nm);

- - nuts for fastening the pins of the ball joints of the ends of the anti-roll bar (35 Nm);

- - ball stud nut (62 Nm);

- - front wheels and front wheel bolts (105 Nm).

Install the anti-roll bar link using tool (Sus1413) and adapter (Sus1734).

Adjust the wheel alignment.