Removing the cylinder head

Put the car on a two-post lift.

Disconnect the battery.

Remove the battery.

Remove the top engine covers

Remove the engine undertray.

Remove the accessory drive belt.

Remove the timing belt.

Remove the front bumper.

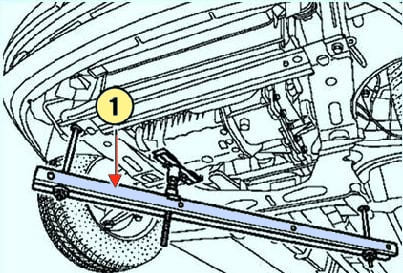

Install the engine support bar (Mot1672) (fig. 1).

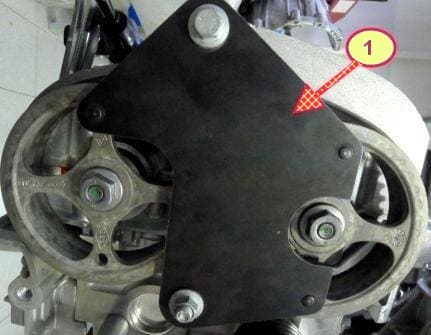

Remove the camshaft pulleys by blocking the shafts with tool (Mot1490-01) (fig. 2).

Remove the fuel rail guard and the fuel rail feed line.

Move the fuel supply line to the side.

Disconnect the brake booster vacuum hose from the intake manifold.

Disconnect the wiring harness from the coolant temperature sensor.

Disconnect the hoses from the thermostat housing.

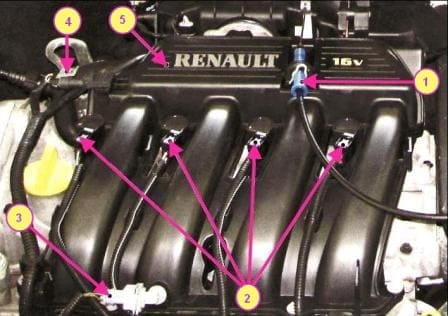

Detach:

- - blocks of wires from ignition coils;

- - block of wires from the air temperature sensor;

- - absolute pressure sensor wire blocks;

- - hose from the canister purge solenoid valve.

- - a block of wires from the upper oxygen sensor.

Disconnect the wire blocks from the injectors.

Connect the holders.

Open the wiring harness.

Remove the coils and spark plugs.

Remove the air filter housing.

Remove the throttle body.

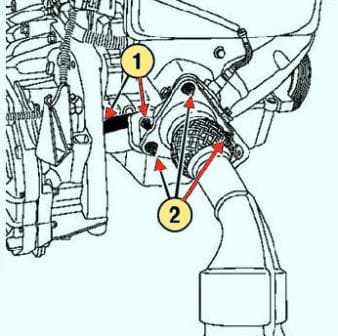

After removing the lifting eye and unscrewing the mounting bolts, remove the intake manifold (Fig. 4).

Removing the outlet pipe flange

Unscrew the mounting bolts and remove the oil separator (Fig. 6)

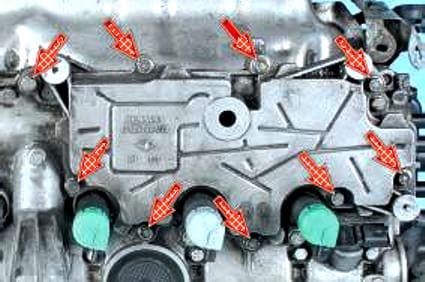

We unscrew the twenty-four bolts securing the cylinder head cover

Pry off with a mounting spatula

Remove the cylinder head cover

Be careful not to damage the mating surfaces of the aluminum alloy parts.

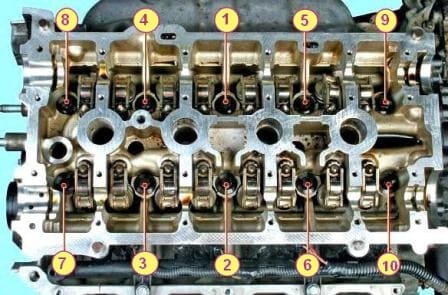

Remove the exhaust camshaft

Remove the intake camshaft

Remove the valve levers

Remove the hydraulic tappets

Place the hydraulic tappets in a vertical position to prevent oil leakage from them.

Remove the mounting bolts and remove the cylinder head.

Install the cylinder head on the stand (Mot1573).

Remove the gasket from the cylinder block.

Cleaning the cylinder head

Clean mating surfaces with Decapjoint (or equivalent) to remove gasket residue from oil pan and engine block mating surfaces.

After applying the composition to the surface to be cleaned, wait about ten minutes, then remove it with a wooden spatula.

Do not let the cleaner come into contact with the paintwork.

Clean the cylinder head thoroughly so that no particles get into the oil outlet and inlet channels.

Oil supply channels can become clogged, resulting in rapid engine failure.

Checking the mating surface of the cylinder head

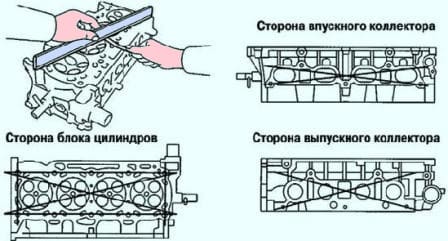

Using a ruler set of feeler gauges, check the flatness of the mating surface of the cylinder head (Fig. 10).

Maximum allowable flatness: no more than 0.05 mm.

Grinding of the cylinder head is not allowed.