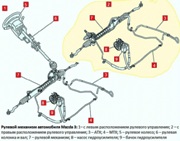

Replacing the boot of the outer hinge of the front wheel drive shaft (F4R engine)

Remove the wheel drive shaft from the corresponding side

Remove the wheel drive shaft covers.

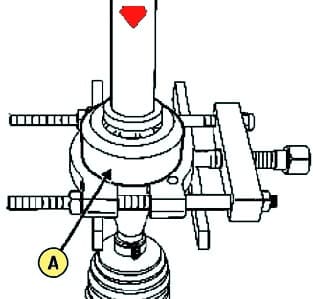

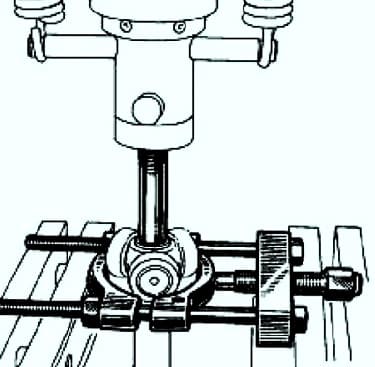

Compress the coarse vibration damper "A" with a press, using a puller as a support (fig. 1).

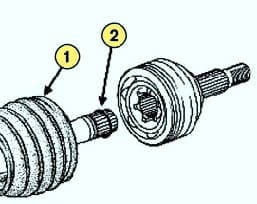

cut the large and small clamps with side cutters, being careful not to damage the grooves of the hinge housing and the drive shaft (Fig. 2).

Cut the cover along its entire length.

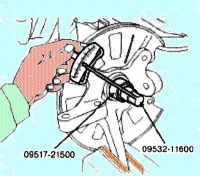

Remove as much grease as possible (fig. 3).

Make sure that you hit the front end of the clip, and not the treadmills of the balls.

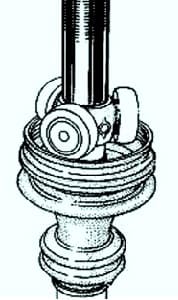

Using a hammer and a punch, apply a few blows to the yoke to disengage the pivot housing from the drive shaft (fig. 4).

Remove the circlip and protective cover.

Installation

Put the cover on the drive shaft from the gearbox side

Do not use solvents to clean the hinge parts.

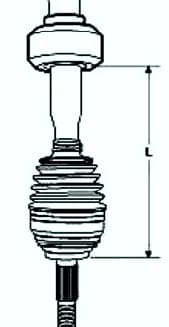

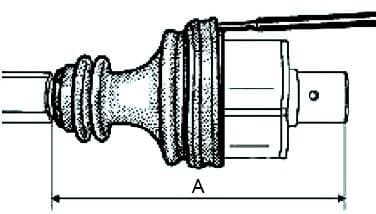

Using a press, press the coarse vibration damper onto the wheel drive shaft until the dimension L = 221 mm + 3 is obtained (Fig. 5).

To facilitate installation of the protective boot, lightly grease the wheel drive shaft (fig. 6).

Install on the drive shaft:

- – small diameter collar;

- - protective cover;

- - new retaining ring.

Taking a brass drift against the hinge body, insert the yoke so that the retaining ring snaps behind the yoke.

The retaining ring must be replaced every time the hinge housing is removed.

Fill boot and outer joint housing with equal amounts of grease.

Locate the edges of the protective boot in the grooves of the pivot housing and drive shaft.

Pull the CV joint by hand to check that the boot bands are properly installed.

Insert a rounded rod between the boot and hinge body to adjust the amount of air inside the hinge.

Install the large collar.

Tighten the small and large clamps onto the boot until they snap into place using the tool (Tav. 1168) (fig. 7).

Crimp the clamps.

Put the spacer "A" into the lower cutouts and squeeze the pliers until it stops.

The pre-swaged yoke can slide over the protective boot. Position it where you want.

Install the wheel drive shaft on the appropriate side.

Removing and installing the protective cover of the outer hinge of the front wheel drive shaft (K4J, K4M engines)

Remove the wheel drive shaft from the corresponding side.

Remove the wheel drive shaft covers.

Cut or saw through two clamps without damaging the groove on the hinge body.

Cut the cover.

Remove as much grease as possible.

Remove the tripod hinge cover (fig. 9).

There is no locking tab on the hinge body, it can be removed without applying force.

Do not remove the rollers from the pins, as the rollers and needles are worked in together and should not be interchanged.

Remove the retaining ring (fig. 10).

Use a press to compress the tripod joint, using the puller as a stop (fig. 11).

Mark the position of the tripod joint before removing it.

Installation

Lubricate the wheel drive shaft lightly to help install the protective boot.

Lubricate the hinge body.

Put the cover on the drive shaft.

Install the small-diameter belt of the boot into the groove of the wheel drive shaft.

Insert the tripod joint, maintaining the position marked during removal.

Install the retaining ring (fig. 12).

Install the hinge body.

Fill the boot and hinge body equally with the required amount of grease.

Locate the protruding bands of the cover in the grooves.

Insert a rounded rod between the boot and the hinge body to adjust the amount of air inside the hinge (fig. 13).

Filling grease into the hinges

Moiykqte br2 grease is applied to the splines of the inner joint shank

Frenbloc glue is applied to the brake mounting bolt

RC 462, RC 463, RC 465, EBJ 82, EBJ 92, EBJ95, TJ 92 joints are lubricated with Mobil CVJ 825 Black Star or Movil EXF 57C

|

Applied Location |

Amount, cm2 |

|---|---|

|

RC 462 HINGE |

110 |

|

RC 463 Hinge |

110 |

|

RC 465 Hinge |

110 |

|

EBJ 82 Hinge |

70 |

|

EBJ 92 Hinge |

105 |

|

EBJ95 Hinge |

110 |

|

TJ 92 Hinge |

135 |