Repair of constant velocity joints consists in replacing their parts and covers

Replace the hinge covers immediately at the first sign of damage (even with pinholes, which are diagnosed by the protrusion of grease on the surface of the boot).

In many cases, even flushing the hinge and changing the lubricant in it will avoid replacing an expensive assembly.

Only internal hinges can be repaired by replacing parts.

If the external hinges fail, you will have to replace them completely together with the drive shaft, since the shaft is made in one piece with the hinge cage.

In operation, only covers can be replaced (with a change of lubricant) on the outer hinges.

To repair the hinges, you will need: a puller to remove the retaining rings or round-nose pliers with thin jaws bent at an angle of 90 °, pliers with thin jaws, side cutters or a hacksaw to remove the clamps for fastening covers, barbs, a hammer, a screwdriver with a flat blade .

To repair the left front wheel drive inner joint, do the following

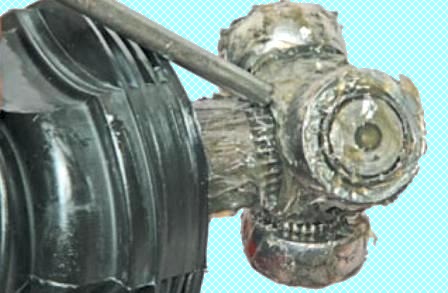

Remove the circlip of the pivot hub by unclenching it with a circlip remover or round nose pliers and removing the circlip from the shaft groove.

Slide the hub with rollers along the shaft splines

Remove the hub from the shaft.

Mark the position of the hub relative to the shaft and reassemble it according to the marks.

If installing a new hub, orient it according to the marks on the old hub.

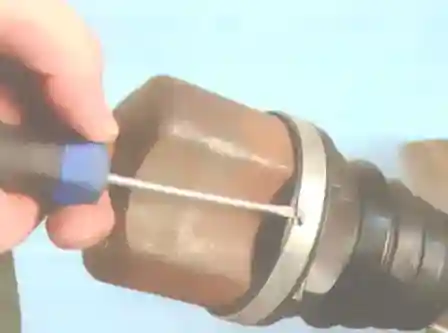

Remove the cover clamp with pliers

The cover fastening clamp can be (and much easier) removed by biting it with side cutters, since a new clamp is necessarily included in the hinge repair kit.

Remove the cover with its holder from the drive shaft.

If it is necessary to replace the oil seal (in case of oil leakage from the gearbox), knock it off the shaft with hammer blows through a wooden block

Using a suitable mandrel (it can be made from a pipe), press the new bearing assembly onto the shaft, keeping the dimension (118 + 0.2) mm between the ends of the shaft and the bearing.

Be careful when pressing on the bearing assembly. In order not to damage the bearing and seal, press the bearing assembly onto the shaft with a press, not with hammer blows.

Install the cover on the shaft, secure it with a clamp, press the hinge hub assembly with rollers onto the splines of the shaft (you can use a suitable head from the tool kit as a mandrel), aligning the marks made during disassembly, and install the retaining ring

To repair the right front wheel drive inner joint, proceed as follows:

Remove the slinger washer from the shank of the pivot housing.

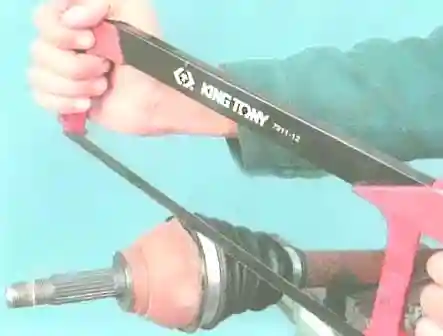

Remove the large clamp securing the case by bending its antennae with a screwdriver

grabbing the clamp with pliers with thin sponges.

To make it easier to remove the clamp, you can cut it with a hacksaw, since the hinge repair kit necessarily includes a new clamp.

When sawing the clamp, be careful not to damage the edges of the groove for the cover on the hinge body.

Similarly, remove the small clamp securing the cover.

Remove the hinge housing.

Remove the spacer spring from the body along with the thrust washer.

Remove the circlip of the pivot hub by unclenching it with a circlip remover or round nose pliers and removing the ring from the shaft groove

Slide the hub with rollers along the splines of the shaft, remove the hub from the shaft.

Mark the position of the hub relative to the shaft and reassemble it according to the marks.

If installing a new hub, orient it according to the marks on the old hub.

Remove the cover from the drive shaft.

If the hinge was disassembled only to replace the boot, remove the old grease from it by washing the inside of the hinge housing and the hub with kerosene or gasoline.

Dry the parts with compressed air.

Install a new boot on the drive shaft.

Make sure that the annular protrusion on the inner surface of the boot in the region of the small diameter belt falls into the groove on the shaft.

To facilitate installation of the boot on the shaft, lubricate the shaft with a thin layer of lubricant designed to fill the hinge.

Press the joint hub assembly with rollers onto the splines of the shaft (as a mandrel, you can use a suitable head from the tool kit), aligning the marks made during disassembly, and install the retaining ring

Put half of the required amount of grease "MOBIL CVJ 825 BLACK STAR" into the case, the total amount of grease is (124±10) g. Put the rest of the grease evenly into the cavity of the hinge body.

Do not decrease or increase the recommended amount of grease in the joint.

Install the spacer spring and thrust washer into the cavity of the hinge body.

Install the hinge body on the rollers of the three-stud hub and put the hinge cover on the body.

Make sure that the annular protrusion on the inner surface of the cover in the region of the large diameter belt falls into the groove on the hinge body.

Remove excess air from the case by lifting the large edge of the case and inserting a round rod, such as a beard, under it.

Without taking out from under the chromeki cover rod, move the parts of the hinge so that between the ends of the small belt of the cover and the shank of the hinge body, a distance of 190 mm is established.

If you do not remove excess air from under the cover and do not set the required length of the hinge before fixing the cover with clamps, the cover may be damaged during operation.

Without changing the position of the hinge parts, remove the rod from under the edge of the cover and secure the cover with clamps.

Install a dirt washer onto the shank of the pivot housing.

To replace the outer joint boots of both drives, proceed as follows:

Remove the inner joints and their covers from the drive shafts.

In addition, when replacing the left front wheel drive boot, press the boot bearing assembly with oil seal and mudguard assembly off the shaft, as described above in this article.

When replacing the cover of the outer hinge of the right front wheel drive, additionally remove the dynamic damper from the drive shaft, overcoming the elastic resistance of the rubber massif of the damper.

Before removing the dynamic damper, measure and note the distance between the ends of the damper and the pivot boot so that the damper can be returned to its original position during reassembly.

Remove the large clamp or cut it with a hacksaw

Remove the small clamps securing the cover with a screwdriver, pliers or sawing with a hacksaw.

Damage of the clamps when removing the cover is acceptable, since the hinge repair kit necessarily includes new clamps.

When sawing the clamps, be careful not to damage the edges of the grooves for the cover on the hinge body and on the drive shaft.

Remove the boot by sliding it over the drive shaft.

To make it easier to remove a damaged boot from the shaft, cut it with scissors or a knife.

To avoid damage to the hinge in operation, after removing the boot, do not separate the hinge housing and the drive shaft.

Remove the old grease from the hinge by washing the cavity with gasoline or kerosene, and dry the hinge with compressed air

Do not use solvents to clean the hinge.

Install a new boot on the drive shaft.

Make sure that the annular protrusion on the inner surface of the boot in the region of the small diameter belt falls into the groove on the shaft

To facilitate pulling the boot along the drive shaft and prevent contamination of the hinge cavity, thoroughly clean the shaft of dirt and rust with fine-grained sandpaper and lubricate with a thin layer of lubricant designed to fill the hinge

Put half of the required amount of "MOBIL CVJ 825 BLACK STAR" grease into the case, the total amount of grease is (294±10) g. Put the rest of the grease evenly into the cavity of the hinge body.

Do not decrease or increase the recommended amount of grease in the joint.

Slide the hinge cover over the chassis. Make sure that the annular protrusion on the inner surface of the cover in the region of the large diameter belt falls into the groove on the hinge body.

Remove excess air from the case by lifting the large edge of the case and inserting a round rod, such as a beard, under it.

If excess air is not removed from under the case, the case may be damaged during operation.

Remove the rod from under the edge of the case and secure the case with clamps.

To drive the right front wheel, install a dynamic damper on the drive shaft, keeping the distance measured before disassembly between the damper and the hinge cover.

Install the dynamic damper on the shaft, orienting it with the end without shoulder towards the outer hinge.

Install all the parts of the inner joint and its cover on the drive shaft, as described above in this subsection.

To increase the service life of the right front wheel drive inner joint, replace the grease in it with fresh grease as a preventive measure.