You will need: keys "for 10", "for 13", "for 14", "for 17", "for 19", "for 21", "for 22", "for 36" (or a special key for the crankshaft pulley fastening nut, in the absence of such a key, you can use a gas wrench),

socket heads "for 12" and "for 13" (or a special key for the cylinder head bolts), a screwdriver, a hammer, an oil filter puller.

If possible, work on a special turntable that provides access to the engine from all sides, as it is very difficult to fix the engine from moving when unscrewing fasteners tightened with a large torque.

Remove the engine from the car.

Similarly to how it was done on the engine installed on the car (excluding operations for disconnecting wires, pipelines and attachments), do the following:

- - remove the oil filter;

- - remove the clutch;

- - remove the flywheel;

- - remove the cylinder head (see "How to replace the Niva Chevrolet cylinder head gasket")

Using the “17” head, unscrew the three bolts securing the front axle gearbox bracket to the cylinder block and remove the bracket.

Using the “13” head, we unscrew the four nuts securing the bracket of the left support of the power unit to the cylinder block and remove the bracket assembly with the pillow

After removing the brackets on their mounting studs and threaded holes in the cylinder block, we mount the plate of the dismantling stand and fix the engine on the stand.

Remove the clutch.

Remove the flywheel and clutch housing cover (see Replacing the crankshaft oil seals of the VAZ-21214 engine).

Using the “13” head, we unscrew the four nuts that fasten the bracket of the right support of the power unit to the cylinder block.

Remove the bracket with the pillow.

Using the “17” head, we unscrew the three bolts securing the generator bracket to the cylinder block and remove the bracket.

Using round-nose pliers, we loosen the clamp fastening to the branch pipe of the outlet pipe of the radiator of the heater, the hose for draining the coolant from the throttle assembly (VAZ-21214 engine) or from the carburetor heating unit (VAZ-21213).

Remove the hose from the branch pipe of the outlet pipe.

With a “10” head, we unscrew the two nuts securing the flange of the heater radiator outlet pipe to the coolant pump housing.

Having unscrewed the nut that secures the tube bracket to the exhaust manifold, remove the outlet tube of the heater radiator and its sealing gasket.

Using the “13” head, unscrew the three bolts securing the coolant pump to the cylinder block and remove the coolant pump assembly and its gasket

On the VAZ-21214, we dismantle the head assembly of the cylinder block with the reservoir, intake pipe and exhaust manifold (see How to replace the Niva Chevrolet cylinder head gasket).

On a carburetor engine, remove the cylinder head assembly with the carburetor, intake pipe and exhaust manifold.

We remove the oil separator of the crankcase ventilation system, the crankcase pan and the oil pump (see Removing and repairing the oil pump of a Niva VAZ-21213, VAZ-21214 car).

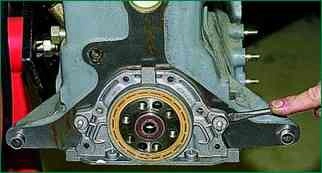

With a “10” head, we unscrew the six bolts securing the crankshaft rear oil seal holder to the cylinder block.

We pry off the holder of the rear oil seal with a screwdriver for the tides and remove the holder assembly with the oil seal.

From the grooves of the gland holder we remove two special bolts (with square heads) securing the clutch housing cover.

Remove the rear oil seal holder gasket

Remove the camshaft drive cover, dismantle the chain, crankshaft sprocket, oil pump drive shaft, chain tensioner shoe (see relevant articles).

Using a “10” spanner, unscrew the bolt securing the bracket for the drain pipe of the oil separator of the engine crankcase ventilation system.

Remove the bracket.

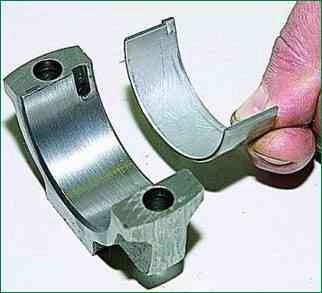

With a “14” head, unscrew the two nuts securing the connecting rod cap (the piston must be at BDC).

Having tapped on the side surfaces of the cover with a plastic-headed hammer, remove the connecting rod cover.

Remove the lower connecting rod bearing shell from the cover.

Leaning on the ends of the rods of the connecting rod bolts, we shift the lower head of the connecting rod from the connecting rod journal of the crankshaft.

Resting the wooden handle of the hammer against the connector of the lower head of the connecting rod, we push the piston into the cylinder and remove the piston with the connecting rod from the cylinder

Remove the upper bearing shell from the connecting rod head.

Similarly, we remove pistons with connecting rods from other cylinders.

Clamp the connecting rod in a vise with soft metal jaws.

With your fingers, carefully (without applying much force), open the lock of the upper compression ring and remove the upper compression ring.

Remove the lower compression ring in the same way

Remove the two oil ring discs.

Remove the oil scraper ring expander

To remove the piston from the connecting rod, pry off the piston pin circlip with a screwdriver and remove it from the annular groove of the piston.

In the same way, we take out the second locking ring of the finger.

Sliding the piston pin, remove it from the hole in the piston.

Remove the piston from the upper head of the connecting rod.

If some parts of the connecting rod and piston group are not damaged and slightly worn, they can be reused.

Therefore, when disassembling, we mark the parts in order to install them in the previous cylinder.

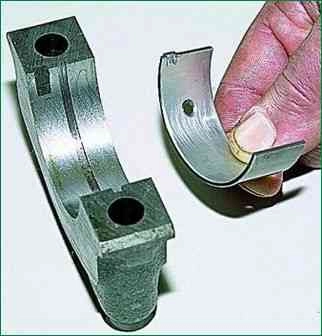

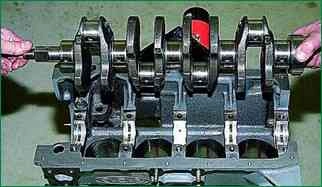

With a “17” head, we unscrew the two bolts securing the crankshaft main bearing cap.

Remove the main bearing cap.

Remove the lower main bearing shell from the cover.

In the same way, remove four more main bearing caps.

Remove the crankshaft from the cylinder block.

We take out the thrust half rings from the grooves of the rear support of the cylinder block

Remove the upper crankshaft main bearing shells from the cylinder block supports

After disassembling the engine, we thoroughly rinse it with gasoline and clean the parts from carbon deposits to check their technical condition.