To compensate for the thermal expansion of the valve, the gap between the end of the valve stem and the adjusting bolt screwed into one of the arms of the rocker arm of the valve actuator is structurally set

With an increased clearance, the valve will not open fully, with a reduced clearance, it will close completely

The need to adjust the clearances in the valve drive is indicated by a distinct loud knock heard when the engine is idling from the driver's seat with the hood closed.

Increased clearances do not lead to emergency engine breakdowns, but cause increased wear of valve mechanism parts.

In addition, with increased intake valve clearances, the filling of the cylinders with a combustible mixture worsens and, as a result, engine power decreases.

With the complete absence of gaps at the exhaust valves, in addition to uneven operation and a decrease in engine power due to a decrease in compression in the cylinders, the plates of these valves and their seats may be burned due to overheating, since the valve that does not fit tightly into the seat is poorly cooled.

The gap is measured on a cold engine (at +20 °C) between the ends of the valve stem and the adjusting bolt with the valve fully closed.

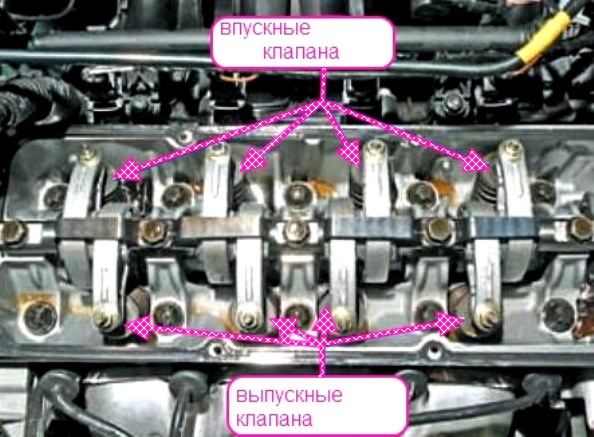

The nominal gap for intake valves is 0.10 ~ 0.15 mm, for exhaust valves - 0.25 ─ 0.30 mm.

After replacing the valves, the initial adjustment for the exhaust valves should be set to a slightly reduced clearance of 0.20-0.25 mm.

Before starting the adjustment, be sure to check and, if necessary, adjust the tension of the timing belt (see "Replacing the timing belt and Renault Logan engine roller").

You will need: all the tools needed to remove the cylinder head cover, as well as a “10” wrench, pliers, a set of flat feelers.

Remove the cylinder head cover (see "Replacing the Renault Logan valve cover gasket").

Set the piston of the 1st cylinder to the TDC position of the compression stroke (see "Setting the TDC of the Renault Logan engine").

In this position, both valves of the 1st cylinder will be closed, and the gaps between the ends of the valves and the adjusting screws will be maximum.

!!! The cylinders are counted from the flywheel.

To set the piston of the 1st cylinder to the TDC position of the compression stroke, the removal of the upper cover of the timing belt is required (to gain access to the alignment marks on the camshaft pulley and on the head cover), which entails laborious preliminary removal operations right suspension support of the power unit.

With enough precision to adjust the clearances in the valve train, the camshaft can be set to the desired position, controlling it visually.

The camshaft must be rotated so that the heels of the rocker arms of the drive of both valves of the cylinder, which is being adjusted, rest on the back of the camshaft cams, and the rocker arms can be moved by "swaying" within the gap.

Loosen the locknut of the adjusting bolt of one of the rocker arms, keeping the bolt from turning with pliers.

Insert a feeler gauge into the gap between the ends of the valve and the adjusting screw.

While holding the locknut from turning, turn the adjusting bolt clockwise until the feeler gauge in the gap can be moved with light force.

Do not tighten the adjusting bolt until the probe is completely pinched, as this will start moving the valve and the gap will obviously be less than normal.

While holding the adjusting bolt from turning, tighten the locknut and check the clearance.

Re-adjust if necessary.

Adjust the gap for the second valve in the same way.

Turn the crankshaft exactly one half turn.

In this position of the crankshaft, both valves of the 3rd cylinder are fully closed and their rocker arms are released.

Adjust the gaps between the ends of the valves and the adjusting bolts of the 3rd cylinder.

Subsequent turns of the crankshaft exactly half a turn, set the pistons of the 4th, and then the 2nd cylinder to TDC of the compression stroke and adjust the clearances for the remaining valves.

Install the cylinder head cover and all removed parts in the reverse order of removal.

If necessary, replace a badly crimped cover gasket.