We remove the clutch discs when they are worn out and when replacing the rear oil seal of the crankshaft and flywheel, as well as when repairing the engine

Clutch discs can be removed without completely removing the gearbox, but only unscrew it and move it away, while securing it.

In the same article, we will look at removing the discs and clutch parts with the gearbox removed.

It is better, of course, to remove the gearbox, because it is better to defect the clutch parts and if there is any defect, then change this part.

Preparing the car for repair.

We install the car on a lift or a viewing ditch.

Disconnect the negative terminal of the battery and remove the gearbox, as indicated in the article - Removing and installing gearbox JH3

If the clutch basket will not change, then you need to mark the relative position of the flywheel and the basket in order to install the basket in place.

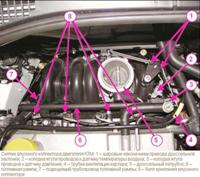

With a head of 11, we sequentially unscrew the six bolts securing the clutch basket (Fig. 1).

The bolts must first be tapped with a soft metal drift.

First, we turn off each bolt one turn so as not to deform the basket body.

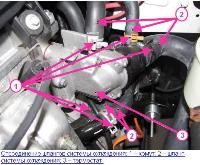

When unscrewing the last bolt, you need to hold the clutch basket (Fig. 2) so as not to drop the driven disk.

You can insert a mandrel to center the disk for insurance.

We take out the basket along with the disk.

We examine and defect the flywheel for cracks and wear (Fig. 3).

Pay attention to the wear of the teeth of the flywheel ring.

During installation, the driven disk must be oriented with the protruding part towards the driving disk, as shown in the figure (Fig. 4).

We orient the driven disk together with the basket using a centering mandrel (Fig. 5).

Insert the mandrel into the input shaft bearing.

Holding the basket with one hand, we bait six basket fastening bolts (Fig. 6).

Tighten the bolts crosswise with a torque of 20 Nm.

When tightening the bolts, they must also be tightened evenly so as not to deform the basket body.

Remove the release bearing (Fig. 7), defect it.

Of course, based on experience, it is necessary to replace the complete clutch assembly when the driven or driving disk is worn.

Having removed the plug, we also inspect it for defects (Fig. 8).

Both grease the surface of the guide bushing and inspect the bushing (Fig. 9).

The bearing is of a closed type, and is not lubricated.

The sleeve must not be lubricated either, as the lubricant may later get on the clutch discs.

We install the parts in place and assemble them in the reverse order.

Tightening torques for main clutch parts

Clutch housing bolt and nut - 44 Nm

Clutch cover to flywheel bolt - 20 Nm

The gearbox mounting points are discussed in the article on removing the gearbox.