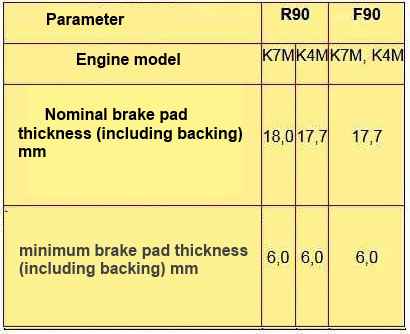

If during the next maintenance or when replacing a wheel it turned out that the wear of the pads exceeded the norms indicated in the table, then you need to change the pads.

The pads must be changed as a set on one axle, regardless of the fact that there is less wear on one wheel than on the other

Remove

We install the car on a lift or raise it with a jack.

Remove the front wheels.

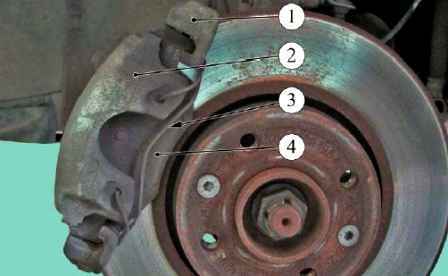

We clean the parts of the front brake with a metal brush.

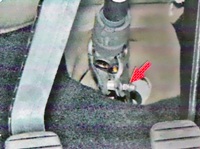

Use a flat screwdriver to spread the pads, while you need to unscrew the reservoir cap on the master cylinder and monitor the brake fluid level.

If the level increases above the norm, you can remove it with a syringe.

For vehicles with K7M engine

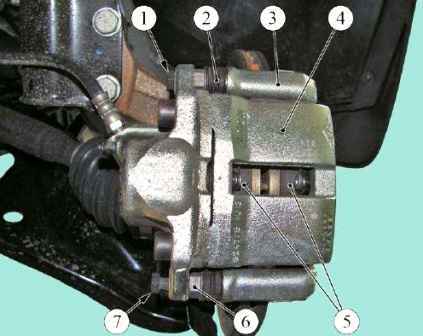

We unscrew and remove the lower bolt 7, Figure 1, fastening the guide pin, holding the guide pin 6 with the key (wrench 17, interchangeable head 13, ratchet wrench).

Turn the caliper 3, figure 2, up and remove the brake pads 4 and noise reduction plates 2.

For vehicles with K4M engine

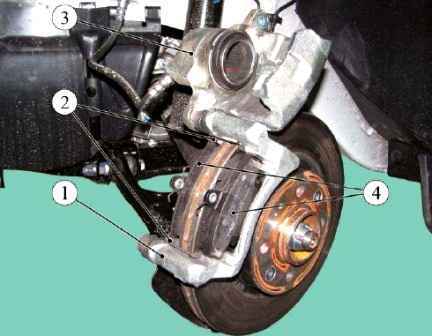

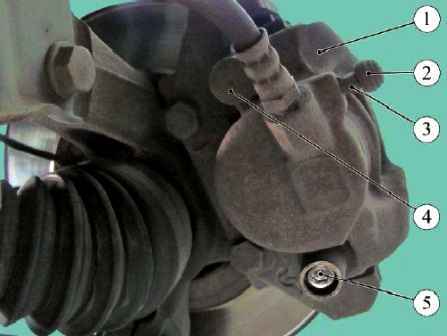

We remove the spring 3, figure 3 from the holes of the front brake caliper 2 (flat screwdriver, pliers).

Use a flat screwdriver to remove the protective caps 4, Figure 4, from the wells of the guide pins.

Unscrew it with a 7 hexagon and remove the guide pins 5.

Remove and hang the front brake caliper to the suspension spring.

You need to be careful with the brake hose so that it does not stretch or twist.

Remove the front pads.

Installation

Check the thickness of the brake pads according to table 1 and replace if necessary.

Check the condition of the dust cap of the operating piston, the dust caps of the guide pins and replace if necessary.

For vehicles with K7M engine

After removing the bolts 1, Figure 1, the fasteners of the guide pins must be replaced, since the bolts are fixed with an adhesive applied to the threaded surface of the bolt.

Reuse of bolts is not allowed.

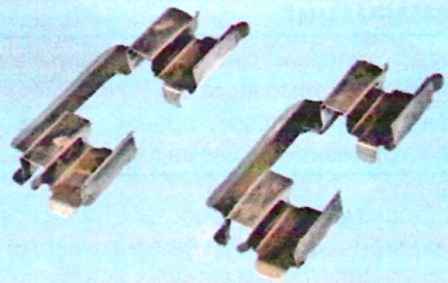

When replacing the pads, replace the noise reduction plates 2, figure 2.

Install new noise reduction plates in the front brake guide, install brake pads.

Turn the caliper down and fix it with the guide pin fastening bolt, first apply 1 g of Frenetanche adhesive on the threaded part of the bolt. ratchet wrench, torque wrench).

For vehicles with K4M engine

Install the brake pads in the front brake guide.

Install the front brake caliper onto the rail and secure it with the guide pins. Torque guide pins 28 Nm (2.8 kgf.m).

Install the protective caps in the wells of the guide pins.

Install the spring (pliers, flathead screwdriver) into the holes of the caliper.

Install the front wheels.

Press the brake pedal 2-3 times, check and, if necessary, top up the brake fluid level in the hydraulic brake reservoir.

Reinstall the brake fluid reservoir cap.

Check the efficiency of the service brake system.

Brake pad parameters

More about replacing the front wheel brake pads

Wrenches required: 13, 15, wheel bolt wrench, sliding pliers, grease

Loosen the front wheel bolts

We raise the front of the car from the side of the pads to be replaced, placing chocks under the rear wheels before this

With a large screwdriver, press the piston all the way into the bottom of the working cylinder to take the brake pads away from the disc

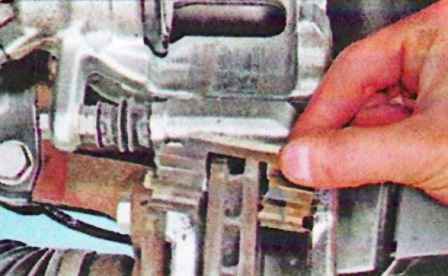

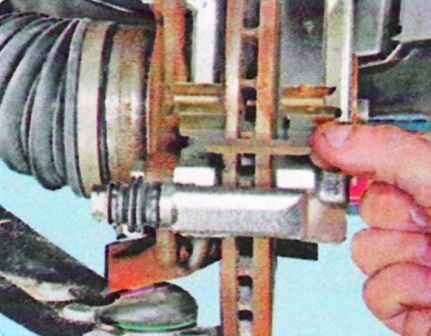

Loosen the caliper guide pin bolt, holding the finger from turning with the second key

And unscrew the bolt

Raise the caliper up

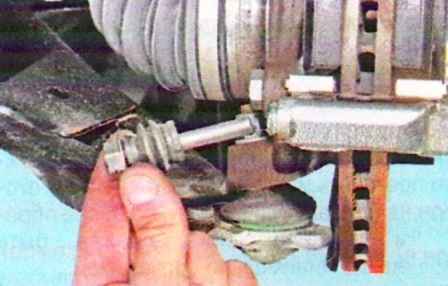

Remove the outer and inner brake pads

This is what the front brake pads look like

Remove the upper and lower pad pressure springs and inspect them

If the springs are deformed or worn, they must be replaced

Remove the caliper guide pins and lubricate them with grease

Install the brake pads in reverse order

We apply a thread locker to the threaded part of the bolts for fastening the guide pins

We also replace the brake pads on the other side of the car

Checking the brake fluid level in the master cylinder reservoir