We remove the front suspension arms for replacement, as well as for repair

Preparing the car for the task

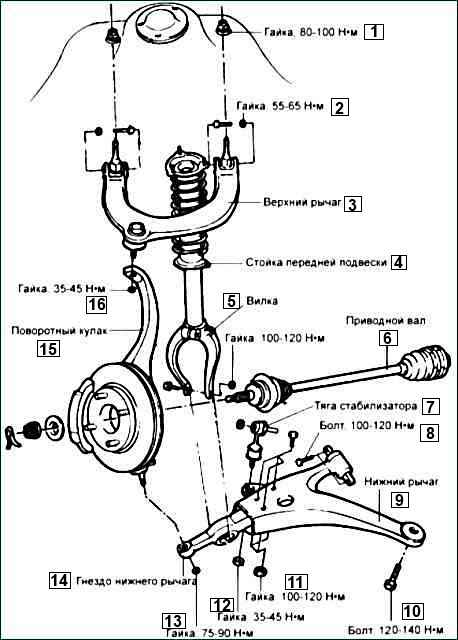

Removing and installing the front suspension lower control arm

Remove the front wheel from the side of the work being done

We loosen the ball joint nuts, but do not unscrew them completely

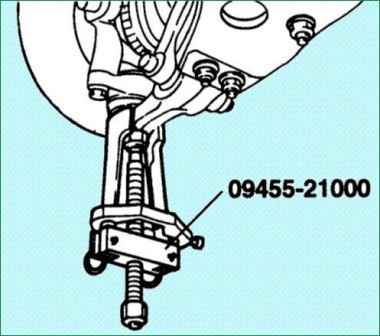

Using a puller, we squeeze the ball joint pin out of the lower arm socket

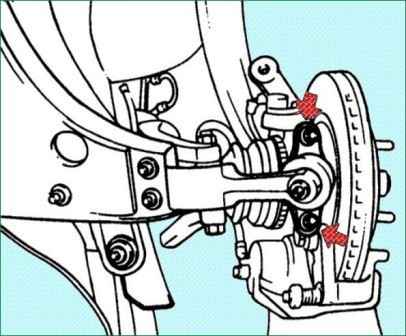

Remove the ball joint

Unscrew the bolt securing the fork to the lower arm socket

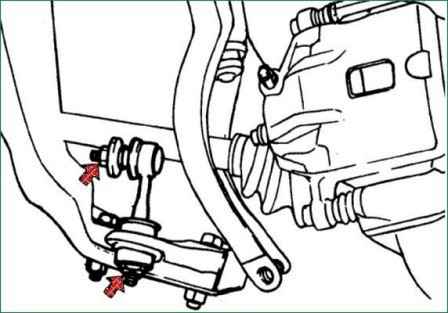

Disconnect the stabilizer link from the lower arm

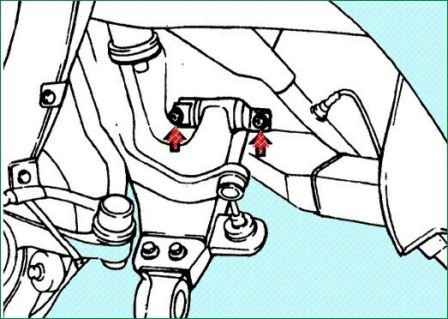

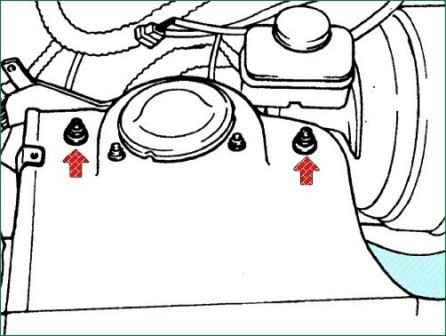

We unscrew the two bolts securing the bushing of the lower arm "A"

We unscrew the bolt securing the bushing of the lower arm "G"

Removing the steering gear

Remove the anti-roll bar

Installation

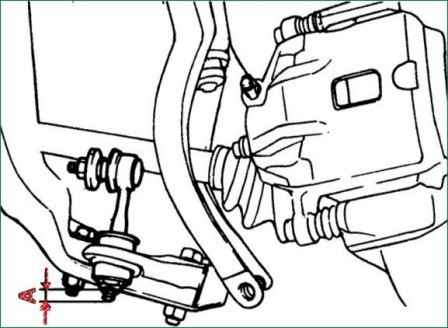

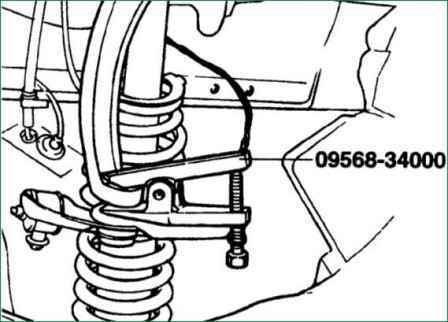

Set the stabilizer rod so that the distance "A" is equal to the standard value

Standard value "A" = 3-5 mm

Next, installation is performed in reverse order

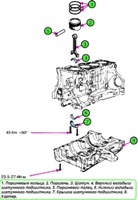

Disassembly of the lower arm

Remove the connector from the lower arm

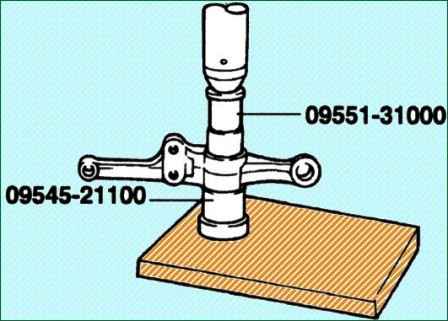

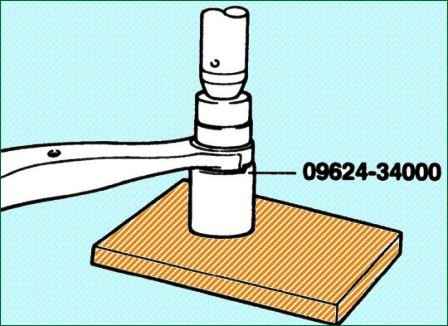

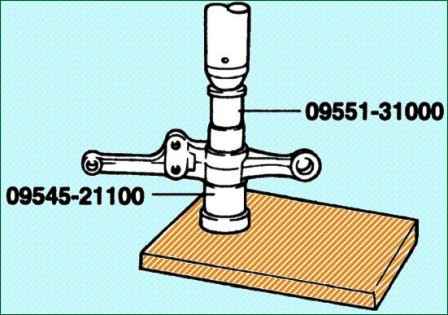

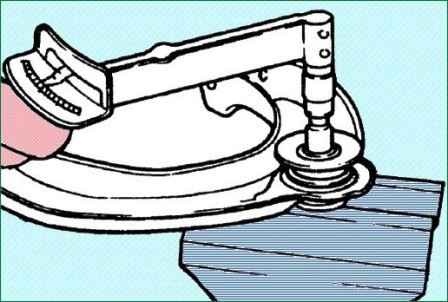

Using a press, remove the shock absorber mounting sleeve

Using a press, remove the lower arm bushing

Checking the lower arm

Checking the bushing for wear and deterioration

Checking the lower arm for bending or damage

Check the ball joint dust cover for cracks

Checking the condition of all bolts

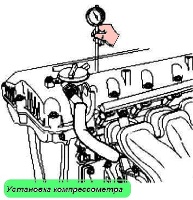

Check the torque required to rotate the lower arm ball joint trunnion.

If there are cracks in the protective boot, replace it and add grease to the hinge.

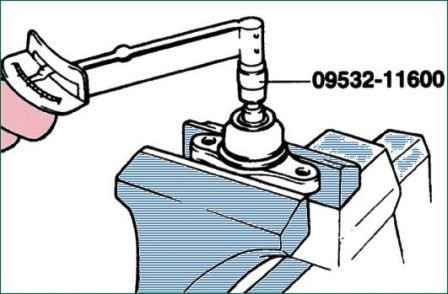

Move the lower arm ball joint trunnion side to side a few times.

Measure the torque required to turn the lower arm ball joint trunnion.

Torque: 0.1 - 0.4 Nm

If torque is below tolerance, replace ball joint.

If the torque exceeds the allowable values, the ball joint can be reused if the torque value does not exceed 1.5 Nm.

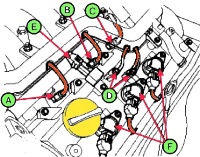

Check the torque required to rotate the stabilizer link ball joint pin.

If there are cracks in the protective boot, replace it and add grease to the hinge.

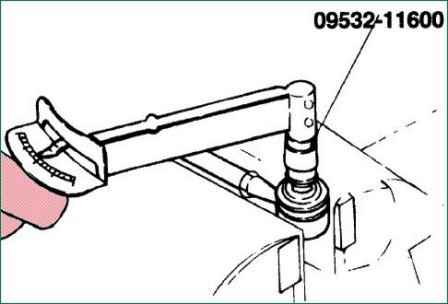

Move the stabilizer link ball joint trunnion side to side a few times.

Screw a self-locking nut onto the ball joint trunnion and then measure the torque required to turn the ball joint trunnion.

Torque: 1.7 - 3.2 Nm

If the torque is too high, replace the stabilizer link.

If the torque is significantly below the allowable value, the ball joint can be reused if it does not jam and does not have excessive play.

Lower arm assembly

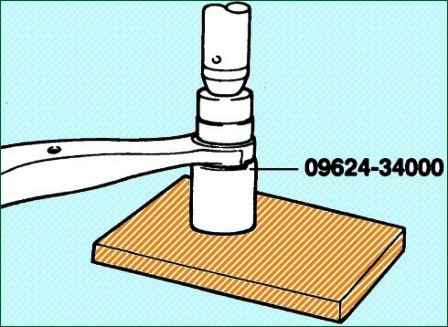

Using a press and suitable nozzles, we press in the shock absorber mounting sleeve

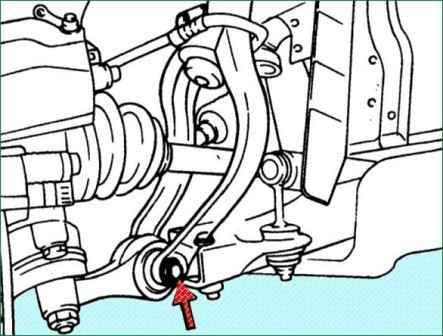

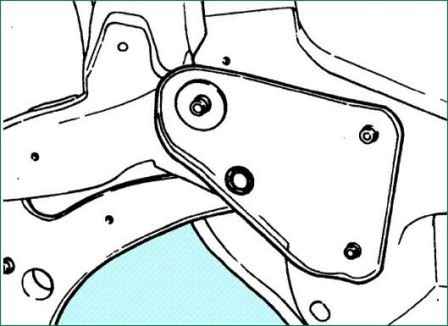

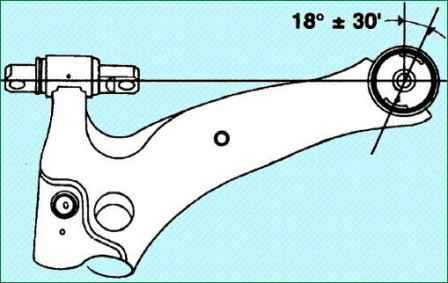

Locate the bushing of the lower arm "G" at the angle indicated in the figure

We press in the bushing of the lower arm

Install the connector on the lower arm

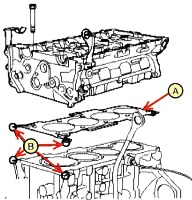

Removing, checking and installing the front suspension upper arm

We prepare the car for the task and remove the front wheel from the side of the work being performed

We loosen the ball joint nuts, but do not unscrew them completely

Using a puller, we squeeze the pin of the ball joint out of the socket of the upper arm

We unscrew the two nuts securing the upper arm of the front suspension

Remove the upper arm of the front suspension

Installation is carried out in reverse order

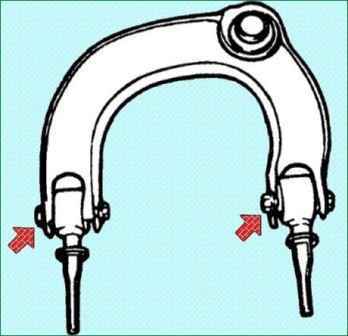

Checking the upper arm

Check the bushing for wear and deterioration.

Check the upper arm for bending or breakage.

Check the torque required to rotate the upper arm ball joint trunnion.

If there are cracks in the protective boot, replace it and add grease to the hinge.

Move the lower arm ball joint trunnion side to side a few times.

Screw a self-locking nut onto the ball joint trunnion and then measure the torque required to turn the ball joint trunnion.

Torque: 1.5 - 2.5 Nm

If the torque is too high, replace the ball joint.

If the torque is significantly below the allowable value, the ball joint can be reused if it does not jam and does not have excessive play.