Before disassembly, the diesel engine must be cleaned of dirt and oil, washed with kerosene or a degreasing solution

For washing, it is recommended to use washing solutions MS6 or MS-8 TU 6-15-978-76 with a concentration of 20-30 g/l at a temperature of 90-100 °C.

Then blow out the diesel with compressed air.

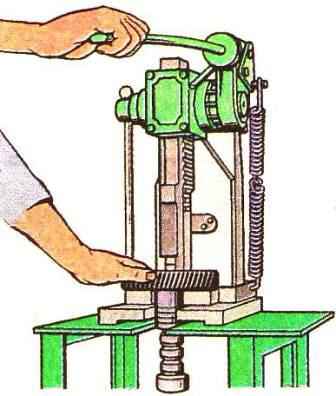

Removal of devices and units from the diesel engine is recommended to be carried out on a stationary rotary stand mod. OPR-989.

The gearbox must be removed from the diesel before installing the diesel on the stand.

Turning of the diesel engine around the horizontal axis of the stand is carried out using a worm gear located on the stand.

During disassembly or assembly, the diesel engine must be fixed in any position when braking the worm gear.

In the process of disassembling the diesel engine, all parts suitable for further operation should be protected from damage.

Parts and normals removed from the diesel engine should be placed in a specially prepared container in which they are transported to the operations of washing, checking and troubleshooting.

Most diesel parts are interchangeable, but some require custom fit with mating part

Diesel disassembly is carried out in the following sequence.

It is necessary to remove the thermostat with a pipe, the liquid pump housing and the fan assembly from the diesel engine installed on the bench with the pallet down.

Then, after unscrewing the nuts securing the exhaust manifold, remove it.

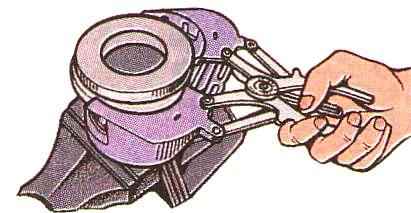

Dismantling the nozzle using a set of inertial universal puller И804.10.000: 1 - handle; 2 - rod; 3 - cargo; 4 - adapter; 5 - nozzle

Using a set of inertial universal puller, dismantle the injectors from the diesel engine (Fig. 1).

Remove the cap and cover from the valve mechanism, the oil supply pipe to the rocker shaft.

Remove the axle rack assembly with the rocker axle and the rocker arms themselves and remove the rods from the cylinder block.

Remove the cylinder head bolts, remove the cylinder head and gasket.

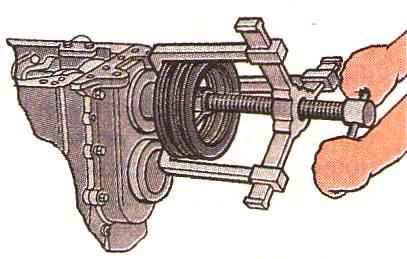

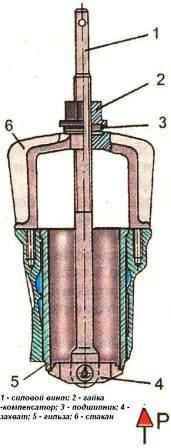

Dismantling the crankshaft pulley using a puller - И803.05.00

Unscrew the bolt securing the fluid pump and fan drive pulley from the end of the crankshaft, remove the diesel front support, and then the pulley using a special puller (Fig. 2).

Remove the timing gear cover, intermediate gear and unscrew the two bolts securing the thrust flange, and then, turning the camshaft, remove it from the cylinder block.

Removing the camshaft gear using a press

Remove the camshaft drive gear using a press and a mandrel, after unscrewing the gear mounting bolt (Fig. 3).

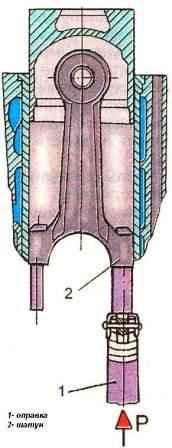

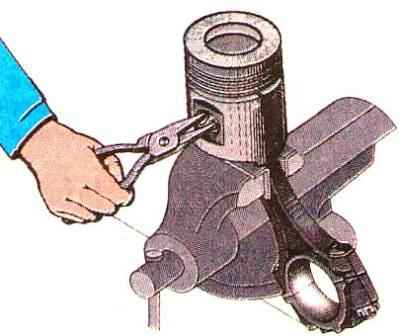

Dismantling the piston with the connecting rod from the cylinder using the mandrel I806.01.200: 1 - mandrel; 2 - connecting rod

Remove the flywheel, seal housing with rubber collar, oil slinger and diesel rear sheet.

Turn the diesel 90 and remove the oil sump and connecting rod caps with liners; remove the connecting rods complete with pistons from the cylinders and put the connecting rod caps in place.

When disassembling the diesel engine, the pistons complete with connecting rods must be removed only upwards (Fig. 4).

Before removing the pistons, remove carbon deposits from the top of the cylinder liner.

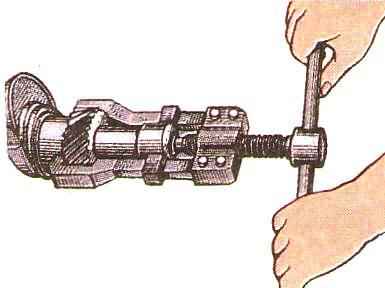

Removing the gear from the crankshaft using a puller 1p-21305

When replacing parts of the sleeve-piston group and the crank mechanism, special attention should be paid to the size groups of parts.

Unscrew the nuts securing the main bearing caps and remove them together with the liners.

Remove the crankshaft and take out the tappets.

Dismantling gears from the crankshaft can be done using a universal puller 1P-21305 (Fig. 5).

Remove the compression and oil scraper rings from the pistons using tool И804.03.000 (Fig. 6).

Remove the circlips from the piston bosses using round nose pliers (fig. 7); press out the piston pins.

Press the cylinder liners out of the block using tool И804.01.000 (Fig. 8).

After disassembly, all parts of the diesel engine must be washed and blown with compressed air.

For washing, it is necessary to use washing solutions MS-6 or MS-8 TU 6-15-978-76 with a concentration of 20-30 g / l at a temperature of 90-100 °.