On some vehicle variants, a mechanical clutch is used

Closed type release bearing, controlled by a clutch release fork and a cable that is directly connected to the clutch pedal.

As the driven and pressure plate wear out, as well as the cable itself stretches, it is necessary to adjust the clutch release drive.

Also, the need to adjust the cable arises when changing the cable or all clutch parts.

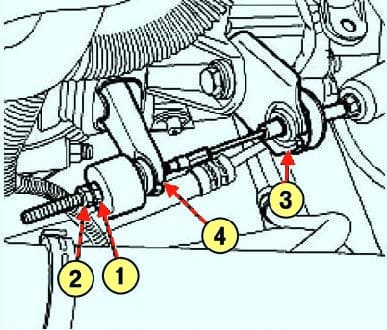

Adjust the travel of the clutch cable with the nut on the end on the gearbox side (fig. 1).

Loosen the locknut.

Adjust the clutch cable travel by loosening or tightening the nut.

Torque tighten (8 Nm) the locknut.

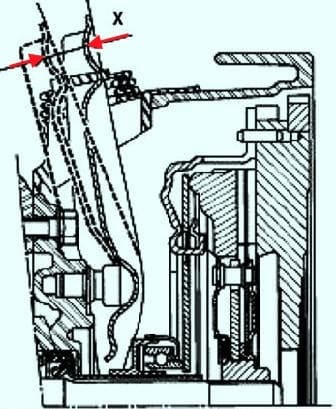

Using a caliper, measure the distance between the cable sheath stopper and the end of the clutch release fork (see fig. 2):

- - at the initial position of the clutch pedal;

- - with the clutch pedal fully depressed.

The travel of the clutch release fork should be: (x)=29.5 mm ±0.5 mm (Fig. 2).

Clutch cable replacement

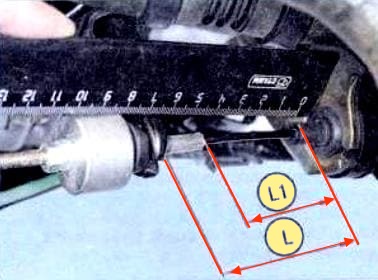

For the convenience of subsequent installation, before removing the cable, we measure the length of the free part of the lower tip of the cable (at the gearbox)

Moving the cable forward, we remove it from the slot of the clutch release fork

Remove the cable sheath damper from the bracket on the gearbox housing

In the cabin, under the instrument panel, disconnect the tip of the cable from the clutch pedal sector.

We remove the cable sheath from the stop in the bulkhead shield and remove the cable, pulling it out of the shield into the engine compartment.

After installing a new cable, we perform the initial cable adjustment.

We measure the dimensions L and L1, respectively, between the end of the damper and the clutch release fork, as well as between the end of the damper and the tip of the cable.

Dimension L should be equal to (86±5) mm, Dimension L1 - (60±5) mm.

If the dimensions do not match, adjust the adjusting nut of the cable end, with the locknut loosened.