Put the car on a two-post lift

Remove the top engine covers

Remove the front wheels.

Remove the left and right fender liner.

Remove the engine undertray.

Drain the gearbox oil.

Drain the engine oil.

Reduce the fuel pressure in the fuel system.

Disconnect the battery.

Drain the refrigerant circuit using a filling station.

Remove the front suspension subframe

Remove the air supply sleeve

We press the clamp of the vacuum booster hose

Disconnect the hose from the receiver fitting

Disconnect the adsorber purge valve hose from the throttle assembly fitting

We press the clamp of the throttle position sensor wiring harness block

Disconnect the block from the connector

We press the retainer of the fuel injector wire block

Disconnecting pads

We press the latch and disconnect the wire block from the camshaft position sensor

Disconnect the fuel line hose from the fuel rail fitting

Press the clamp of the camshaft adjuster wire block

Remove the block from the regulator

Disconnect the wiring harness connectors from the ignition coils

Press the retainer of the manifold absolute pressure sensor harness block in the receiver

Disconnect the block from the sensor

Press the latch and disconnect the block from the canister purge valve

Press the retainer of the air temperature sensor wire block in the receiver

Disconnect the block from the sensor

Press the wire block retainer away from the knock sensor

Disconnect the block from the sensor

Press the retainer of the oil pressure sensor wire block

Disconnect the block from the sensor

Unscrew the nut of the generator power wire

Disconnect the power wire from the generator output

Press out the cable harness retainer

Disconnect the block from the generator

We press the clamp of the block of wires of the pressure sensor of the air conditioning system

Disconnect the block from the sensor

Pry off the wire clamp

Flip out the bracket and move the wires to the side

Squeeze the bent ears of the heater outlet hose clamp

Disconnect the hose from the coolant hose fitting

Disconnect the radiator outlet from the coolant hose fitting

Disconnecting the radiator inlet pipe

Disconnect the heater supply hose from the water distributor

Disconnect the heater hoses from the brackets

We press the clamp of the block of wires of the coolant temperature sensor

Disconnect the block from the sensor

We press the latch and disconnect the wire block from the crankshaft position sensor

Unscrew the ground wire bolt

Disconnect the ground wire from the gearbox housing

We press the latch and disconnect the pipeline from the clutch slave cylinder

Plug off the piping with the bleed cap of the working cylinder

Disconnect the exhaust pipe from the exhaust manifold

We press the retainer of the cable block of the emergency drop in oil level sensor

Disconnect the block from the sensor

Remove the front wheel drives

We press the retainer of the reverse sensor wire block

Disconnect the block from the sensor

We press the clamp of the block of wires of the control oxygen sensor

Disconnecting pads

Unscrew the nut of the starter ground wire

Unscrew the nut of the starter power wire

We remove the air conditioning compressor without disconnecting the pipelines, and fix it

Disconnect the transmission control cables from the selector levers and remove them from the bracket

Setting aside the wiring harness

Install the supports under the power unit

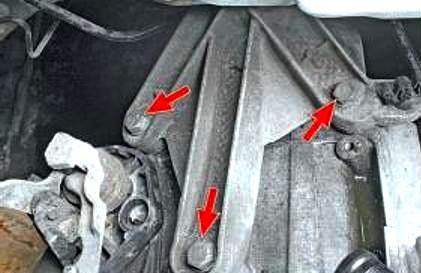

We unscrew the five bolts of the right suspension support of the power unit

Remove the support bracket

We unscrew the three bolts securing the support to the gearbox housing

Check again that all wires, hoses and attachments are disconnected from the engine.

Lower the engine on its stands, keeping it from falling.

If it is not possible to lower the engine on supports, hang the front of the car (raise the car on a lift) to a height sufficient to remove the power unit from under the car, and place reliable supports under the body.

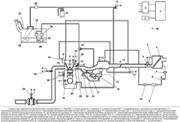

Install the engine, as well as all removed components and parts, in the reverse order of removal, taking into account the following:

- - before installing the power unit, clean the threaded holes for fastening its supports with a tap;

- - be sure to replace the exhaust pipe gasket with a new one;

- - when connecting wires and pipelines, carefully monitor their location in the engine compartment, avoiding contact with heating and moving elements of the power unit.

Torque tighten:

- - bolts of the upper fastening of the front panel of the body (21 Nm);

- - bolts of the lower fastening of the front panel of the body (44 Nm);

- - front subframe bolt (105 Nm);

- - subframe rear mounting bolt (21 Nm);

- - wheel bolts (110 Nm).

Add brake fluid to the reservoir.

Bleed the hydraulic clutch.

Refill the gearbox with oil.

Fill the engine with oil.

Fill the cooling system with fluid.

Fill the refrigeration circuit with refrigerant using a filling station.

Correcto secure the brake rod and ABS speed sensor wires.

Do not twist the brake hose.

Connect the battery.

Bleed air from the cooling system.

Torque tighten (4 Nm) the bolts securing the battery cover.