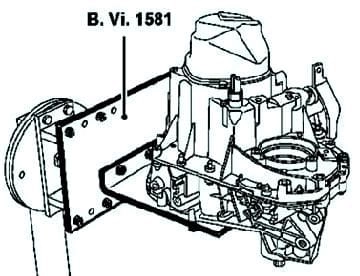

Mount the mount plate (BVi1581) to the stand (Desvil).

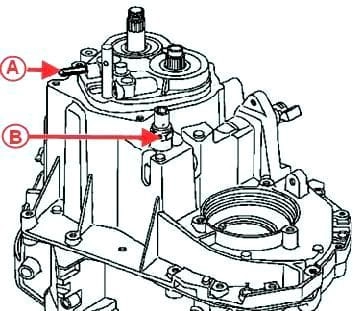

Install the gearbox on the mounting plate (BVi1581) (fig. 1).

Remove the clutch release slave cylinder.

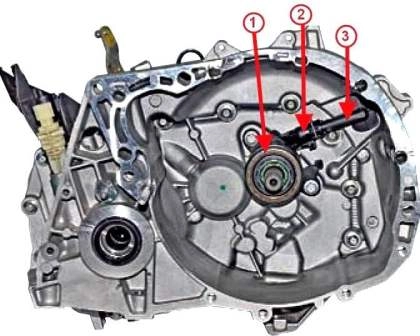

Unscrew the bolts located inside the crankcase (fig. 2).

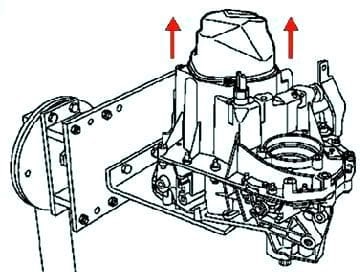

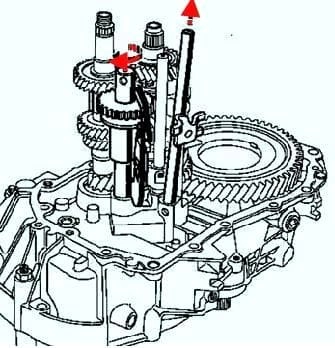

Remove the rear casing strictly along the horizontal axis of the box, as it includes a lubricant capsule located in the input shaft hole (Fig. 3).

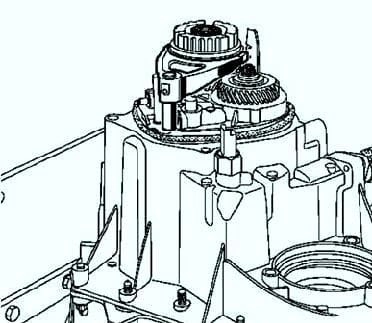

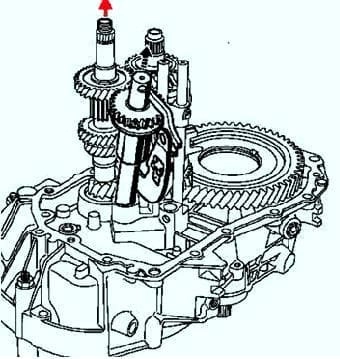

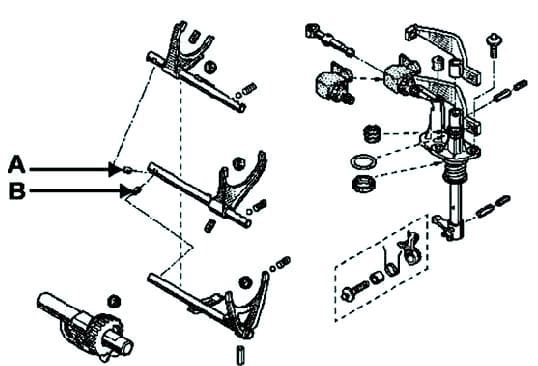

Engage the first gear with the shift lever, and the fifth one by sliding its fork along the stem (Fig. 4).

Remove the output shaft bolt and remove the input shaft nut.

Using a punch (BVi31-01), knock out the fifth gear fork pin.

Remove the fifth gear fork and gear.

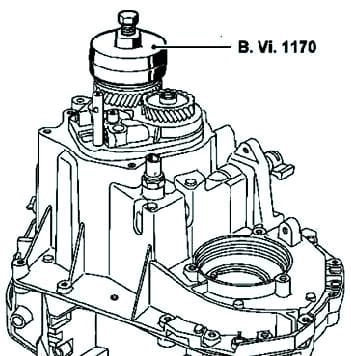

Remove the 5th gear hub using tool (BVi1170).

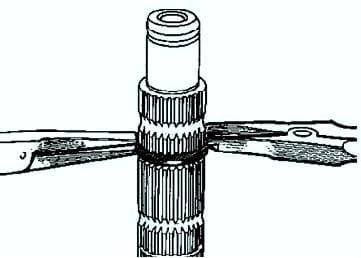

Install the accessory gear (BVi1170) into fifth gear by turning it to align the splines of the gear and hub

Remove the fixture together with the hub (fig. 6)

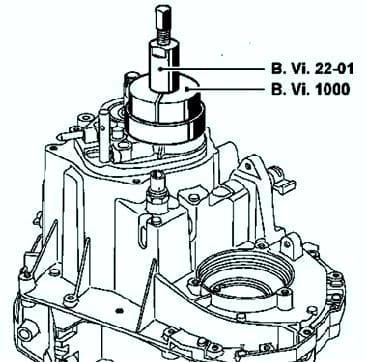

Remove the 5th gear fixed gear using tools (BVi22-01 and BVi1000) (fig. 7)

Remove the outer crankcase bolts.

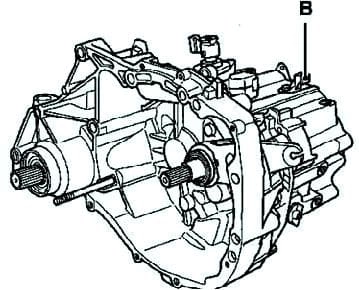

Remove speed sensor B (for semi-automatic transmission JH1) (fig. 8)

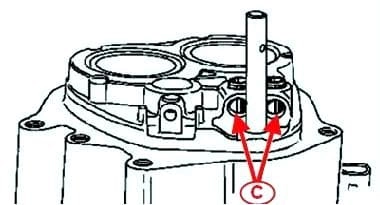

It is recommended to put two magnets or block holes C in order not to lose balls and springs for fixing rods 1/2 and 3/4 (Fig. 9)

Remove reverse stem A and reverse contactor B (fig. 10)

Press the shift rod outwards.

Disconnect and remove the crankcase.

Turn the reverse axle assembly to the left and remove the reverse/fifth shift fork stem (fig. 11)

Raise the input shaft slightly and remove the reverse gear axle assembly (Fig. 12)

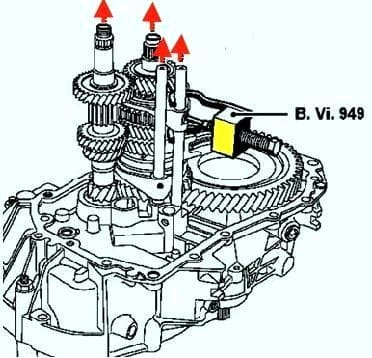

Disconnect the 3/4 yoke pins with the tool (BVi949) and remove the stem and yoke 3/4, input and output shaft assembly with stem and yoke (fig. 12)

Simultaneously remove the input and output shaft assembly with the stem and yoke 1/2 (Fig. 13)

Removing gears

Clamp the output shaft in a vise with jaws, and then remove all gears.

When removing and installing circlips, use circlip pliers on one side and pliers on the other (fig. 15).

Check Details

The teeth of gears and clutches should not be excessively worn or serrated.

Also, make sure that there are no signs of friction or excessive wear on the surfaces of the shafts and the inner surfaces of the gears.

It is recommended to mark the position of the gear couplings relative to the hubs.

Replacing bearings in the crankcase

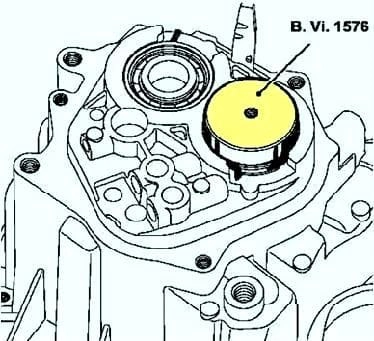

Spread the circlips with suitable pliers and press the bearing into the crankcase using tool (B.Vi1576) (fig. 16).

JH3 gearbox disassembly can be found in the article - "JH3 gearbox disassembly"