To remove the air supply line from the air-to-air cooler (F4R engine), disconnect the hose using tool (Car1363)

Do not use brake cleaners or other cleaning products.

Wipe the air cooler seat and hose with a lint-free cloth.

If the hose is not being replaced, reinstall the clamp.

If the nozzle or air-to-air cooler is damaged, be sure to replace it.

Failure to follow this procedure may cause air leakage or hose disconnection.

Remove

Put the car on a two-post lift.

Remove the top engine covers.

Remove the front wheels.

Remove the left and right fender liner.

Remove the engine undertray.

Drain the gearbox oil.

Drain the engine oil.

Disconnect the battery.

Drain the refrigerant circuit using a filling station.

Remove the subframe side reinforcements and front bumper.

Disconnect the hood release cable.

Disconnect the washer tubes.

Drain the engine cooling system.

Remove the mounting bolts and remove the front body panel.

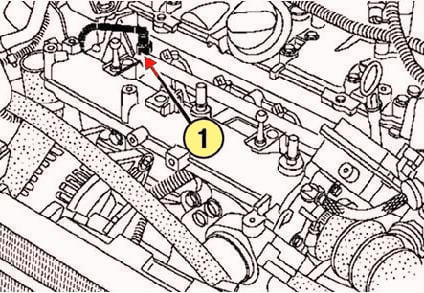

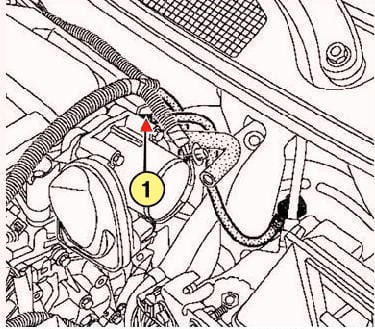

Disconnect the fuel supply line from the fuel rail (fig. 1).

Disconnect the supply hose from the radiator of the engine cooling system using the tool

Disconnect the wire blocks from the electric fan of the engine cooling system.

Disconnect the engine cooling fan harness.

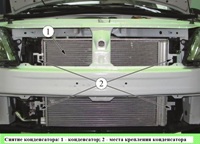

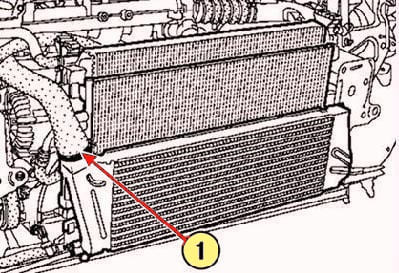

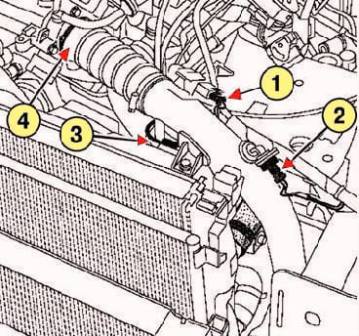

Disconnect the air line from the air-to-air cooler (fig. 2).

Detach:

- - a block of wires from the boost pressure sensor;

- - block of wires from the air temperature sensor;

- - a block of wires from the resistor of the electric fan of the engine cooling system.

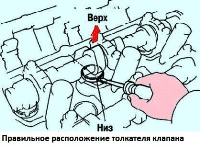

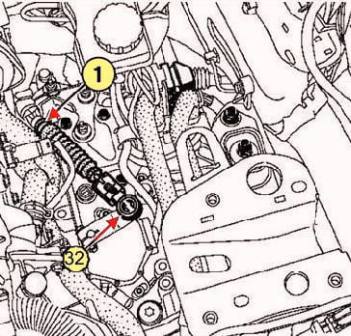

Move aside the air duct (fig. 3).

Remove the air filter outlet duct.

Disconnect the expansion tank hoses from the engine cooling radiator.

Disconnect the pressure sensor connector on the condenser air conditioning downpipe.

Remove the refrigeration lines from the condenser and the refrigeration lines between the compressor and the receiver-drier.

Be sure to plug the openings of the pipelines and the reducer in order to enter the system.

Remove the engine cooling system radiator assembly with condenser.

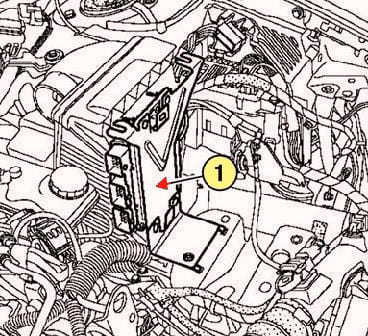

Disconnect the ECU connectors.

Remove the mounting bolts and remove the shelf for the battery.

Move aside the canister purge solenoid valve.

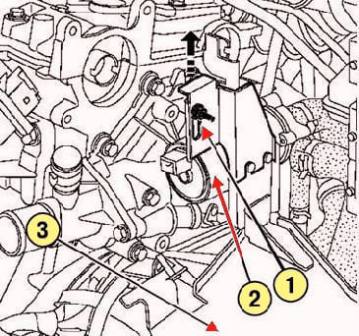

Unscrew the bolt, pull the water pump mounting post and, moving the water pump aside, remove the water pump bracket (Fig. 4).

Remove the complete ECU with the bracket (Fig. 5).

Remove the air filter housing.

Disconnect the relay box harness connectors.

Disconnect the ground bus.

Remove the brake booster suction hose (fig. 6).

Disconnect the downstream oxygen sensor connector.

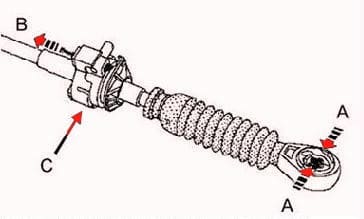

Disconnect the selector and shift cables from the gearbox.

Disconnect the cables from the levers on the gearbox by squeezing the end of the cable at points A, pull the latch in the direction of B and lift the cables at point C , as shown in Figure 7.

Remove the ball end of the multifunction switch cable (fig. 8).

Remove the multi-function switch cable by releasing the cable sheath stopper.

Place a rag under the master cylinder.

Remove the retainer from the fitting on the intermediate pipe of the master cylinder.

Disconnect the tube from the slave cylinder. Insert plugs into the holes.

Remove the supply line to the working cylinder.

Remove the right front wheel drive shaft.

Remove the left front wheel drive shaft.

Remove the fastening parts of the exhaust pipe of the exhaust system,

Remove the upper and lower tie rods.

Remove the stretcher.

Install a hydraulic crane with a hoist or chain.

Mark the position of the engine suspension mount relative to the body.

Remove the engine mount.

Remove the transmission swingarm support.

Turn the engine/transmission assembly and remove it.

Installation

Install the engine and gearbox assembly on the vehicle.

Install:

- - support of the pendulum suspension of the engine;

- - support of the pendulum suspension of the gearbox;

- – lower jet thrust;

- - upper jet thrust;

- – left front wheel drive shaft;

- - right front wheel drive shaft.

The rest of the components are installed in the reverse order of removal.

Torque tighten:

- - bolts of the upper fastening of the front panel of the body (21 Nm);

- - bolts of the lower fastening of the front panel of the body (44 Nm);

- - front subframe bolt (105 Nm);

- - subframe rear mounting bolt (21 Nm);

- - wheel bolts (110 Nm).

Add brake fluid to the reservoir.

Bleed the hydraulic clutch.

Refill the gearbox with oil.

Fill the engine with oil.

Fill the cooling system with fluid.

Fill the refrigeration circuit with refrigerant using a filling station.

Properly secure the brake hose and ABS speed sensor wires. Do not twist the brake hose.

Connect the battery.

Bleed air from the cooling system.

Torque tighten (4 Nm) the bolts securing the battery cover.