The camshaft is replaced in the following cases:

- the pressure in the engine lubrication system has dropped.

The cause of this malfunction is often increased wear on the camshaft journals and sockets in the camshaft bearing housing.

In this case, the camshaft is replaced simultaneously with the bearing housing;

- the sound of valves with serviceable hydraulic bearings of the drive levers.

Caused by increased wear of the camshaft cams due to the use of low-quality engine oil or damage to the oil filter.

In this case, the bearing surfaces of the valve actuator levers are usually damaged, which in this case must be replaced simultaneously with the camshaft.

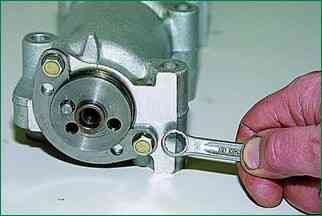

You will need: keys "for 10", "for 13", "for 17", "for 24".

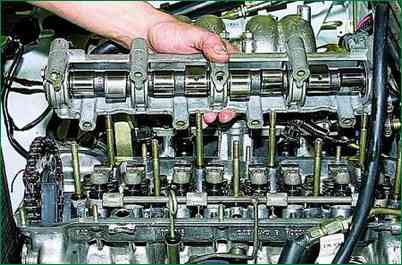

Remove the camshaft bearing housing together with the shaft (see "How to replace Niva Chevrolet hydraulic lifters").

Disassemble the camshaft bearing housing by unscrewing the two bolts securing the camshaft thrust flange.

Remove the thrust flange from the groove in the front bearing journal of the shaft.

Remove the camshaft from the bearing housing by sliding it forward.

When removing the camshaft from the bearing housing, be careful not to damage the surfaces of the supports under the camshaft journals with the sharp edges of the cams.

Inspect the camshaft.

On the working surfaces of the necks, scuffing, nicks, scratches, aluminum enveloping from the bearing housing are not allowed.

On the working surfaces of the cams, wear of more than 0.5 mm is not allowed, as well as scuffing and wear of the cams in the form of a cut. Replace the shaft with detected defects

Measure the diameters of the bearing journals of the shaft. They should be (counting from the front):

- 1 - 45.915-45.931 mm;

- 2 - 45.615-45.631 mm;

- 3 - 45.315-45.331 mm;

- 4 - 45.015-45.031 mm;

- 5 - 43.415-43.431 mm

Inspect the camshaft bearing housing.

Cracks on the hull are not allowed. On the working surfaces of the supports under the necks, no marks, scratches, scuffs, excessive wear are allowed.

Measure the inside diameters of the camshaft housing bearings.

They should be (counting from the front):

- 1 - 46.000-46.025 mm;

- 2 - 45.700-45.725 mm;

- 3 - 45.400-45.425 mm;

- 4 - 45.100-45.125 mm;

- 5 - 43.500-43.525 mm.

If the gaps between the shaft journals (see operation 7) and the bearings exceed 0.2 mm (wear limit), replace the housing and, if necessary, the camshaft.

Install the new camshaft and bearing housing, as well as all removed components and parts, in the reverse order of removal.

Before installing the distributor lubricate the working surfaces of the journals and camshaft cams with engine oil.

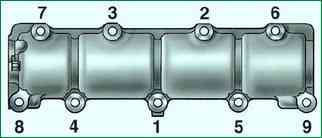

Tighten the bearing housing nuts in the order shown in fig. 11.

The order of tightening the nuts of the camshaft bearing housing