Some cars are additionally equipped with an air conditioning system, which is designed to reduce the temperature and humidity in the cabin

The air conditioning system is turned on by pressing the air conditioner switch button located on the instrument panel, and the warning light located in the switch button lights up.

Before turning on the air conditioning system, it is imperative to turn on the heater fan and move the temperature control knob to the left, to the blue sector.

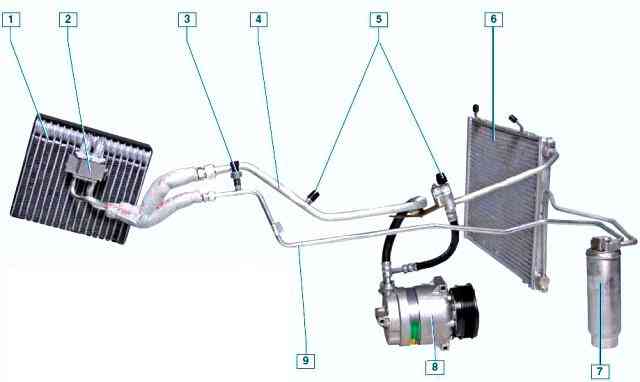

Most of the air conditioning system components are located in the engine compartment.

In the passenger compartment there is only an evaporator located under the instrument panel in place of intermediate air ducts between the heater and its fan.

The evaporator serves to exchange heat between the air entering the passenger compartment and the refrigerant circulating in the air conditioning system.

As you move through the evaporator tubes, the refrigerant turns into vapor.

The process proceeds with the absorption of heat, the evaporator fins are cooled, the cold is "removed" from the fins and is sent to the cabin with the help of the heater fan, helping to lower the internal temperature in the cabin.

The low pressure refrigerant in the gaseous state flows from the evaporator to the compressor, which pressurizes the refrigerant.

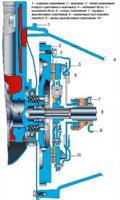

The air conditioning compressor is located on the right side of the engine block, below the engine cooling pump.

The compressor is driven by a V-ribbed belt from the accessory drive pulley.

An electromagnetic clutch is built into the compressor pulley, which turns the compressor shaft on and off from the pulley according to signals from the engine management system controller.

Refrigerant vapor from the compressor enters under high pressure into a condenser located in front of the radiator of the engine cooling system.

Passing through the condenser cells, the refrigerant is cooled by the oncoming air flow and by means of cooling system fans.

This changes the refrigerant from a gaseous state to a liquid state.

Next, high-pressure liquid refrigerant enters the receiver, which is fixed under the right headlight in the cavity formed by the right fender, mudguard, front bumper and right bumper mudguard.

The receiver simultaneously performs several functions: as a filter, it cleans the refrigerant from impurities that have got into it; as a dehumidifier, it absorbs moisture that condenses inside the air conditioning system, and also serves as a reservoir for refrigerant.

From the receiver, the refrigerant enters the reducer located directly on the evaporator.

The reducer is a throttle valve, at the outlet of which the pressure and temperature of the refrigerant decrease sharply, as a result of which the refrigerant passes from a liquid state to a gaseous state.

In this form, the refrigerant passes through the evaporator again, cooling the air entering the car interior.

From the evaporator, the refrigerant is sucked in again by the compressor, and the work cycle is repeated.

Valves are installed on the high and low pressure pipelines for charging and discharging refrigerant from the air conditioning system.

A refrigerant pressure sensor is installed on the high pressure pipe.

The pressure sensor sends a signal to the controller, which controls the electric fans of the engine cooling system, depending on the refrigerant pressure and vehicle speed.

In addition, according to the pressure sensor signals, the controller turns off the air conditioning compressor if the refrigerant pressure in the system is too low or too high.

A shut-off valve is installed in the fitting under the pressure sensor, which closes when the sensor is unscrewed, so there will be no refrigerant leakage from the air conditioning system when the pressure sensor is replaced.

The refrigerant in the air conditioning system is mostly under high pressure.

During work related to depressurization of the air conditioning system, avoid contact with eyes, skin and respiratory tract.

Any work with refrigerant should be carried out only in a ventilated area.

When charging the air conditioning system, use only materials recommended by the manufacturer.

It is forbidden to carry out welding or soldering work on the components of the air conditioning system.

Repair and maintenance of the air conditioning system research should be carried out at specialized services.

Special equipment is used to search for leaks in the system, and a special contrast agent must be injected into the system.

After removing the refrigerant from the system, it is imperative to evacuate the air to remove residual moisture.

Before filling the air conditioning system, it is necessary to add special oil recommended by the manufacturer.

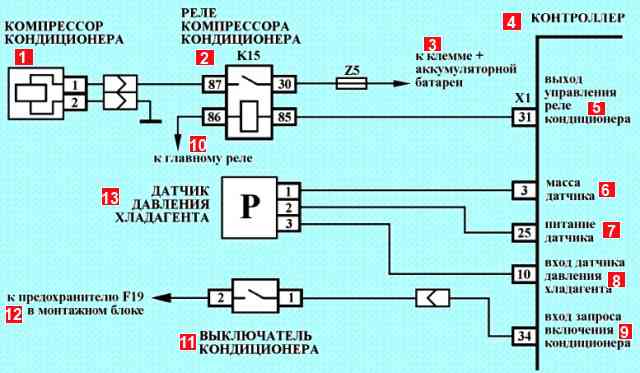

The connection diagram of the car's air conditioning system is shown in fig. 2.

This air conditioning system uses an analog type pressure sensor.

The pressure sensor is installed on the high pressure pipeline.

The pressure sensor is supplied with 5 V.

The output of a pressure transducer is directly proportional to the pressure applied to it and varies linearly between 0.25 V and 3.35 V as the pressure changes from 100 kPa to 2400 kPa.

Analysing the signal of the pressure sensor coming to the contact "X1/10" of the controller, the controller calculates the pressure of the refrigerant in the pipeline.

Based on these calculations, the controller decides whether to allow the air conditioner to turn on.

When the driver turns on the air conditioner switch located on the instrument panel, the ECM contact "X1 / 34" receives a request signal to turn on the air conditioner.

When requested, the controller adjusts the throttle opening angle to compensate for the additional load placed on the engine by the A/C compressor.

The value of the crankshaft speed at idle can increase up to 1000 min -1. After that, the controller through the relay turns on the clutch of the air conditioning compressor.

Thus, the air conditioning compressor turns on under the following conditions:

- - more than 5 seconds have passed since the engine was started;

- - on-board network voltage does not exceed 16.5 V;

- - throttle valve is open no more than 68%;

- - the driver turned on the air conditioner;

- - the pressure of the refrigerant in the high pressure pipeline is within a certain range.

When the air conditioner is turned on, regardless of the temperature of the coolant, a reduced performance of the electric fans of the engine cooling system is turned on.

The controller turns on the electric fans of the engine cooling system at maximum performance if the refrigerant pressure in the high pressure pipeline exceeds 1600 kPa and turns off when the pressure drops to 1300 kPa.

In the event of a fault in the refrigerant pressure sensor, the controller will turn off the air conditioner.

Possible malfunctions of the air conditioning system

- Possible malfunctions

Correction methods

When the air conditioner is on, the air in the cabin is not cooled

- Insufficient charge of refrigerant in the air conditioning system, refrigerant leak, lines deformed or kinked

You need to check the entire system

- Heater blower motor defective, fuse blown or relay defective

Check the operation of the heater blower motor. Replace the blown motor and relay protection fuse.

- Loose compressor drive belt

Tighten the belt

- Compressor clutch won't engage

Check the clutch engagement circuit. Replace the defective clutch.

- A/C switch does not work

Replace the switch

- The controller does not output a signal to the relay for switching on the electromagnetic clutch of the air conditioning compressor (a fuse is blown or the relay is faulty).

Replace the magnetic clutch circuit protection relay or fuse.