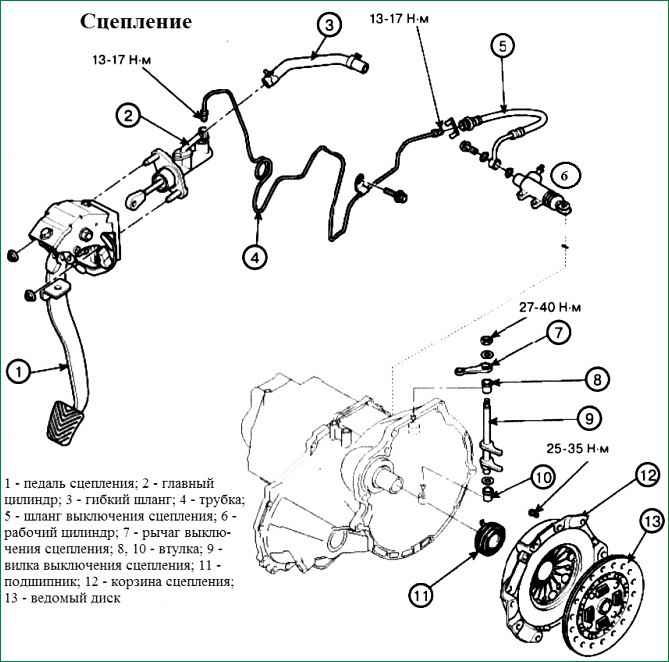

For KIA Magentis vehicles equipped with a manual transmission, a dry single-plate clutch with a central diaphragm spring is installed

The clutch is located between the engine and the gearbox and is designed to disconnect and connect the flywheel located on the engine crankshaft and the gearbox input shaft.

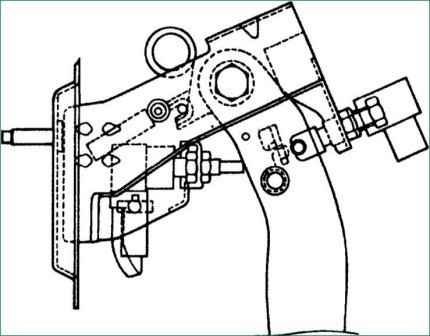

The clutch consists of a driven (friction) disc, a clutch cover with a pressure plate and a diaphragm spring, as well as a clutch release mechanism.

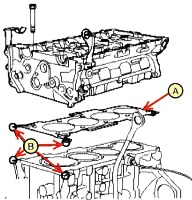

The pressure plate is mounted in a stamped steel casing, attached with six bolts to the engine flywheel.

The driven disc is mounted on the splines of the input shaft of the gearbox and is clamped by a diaphragm spring between the flywheel and the pressure plate.

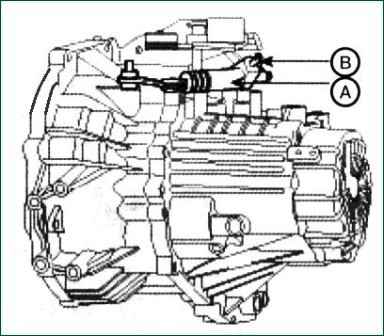

The clutch release bearing is mounted on a guide sleeve pressed into the clutch housing and moves along the sleeve with a fork, which in turn drives the clutch release hydraulic slave cylinder.

The hydraulic clutch release includes the following:

- - master clutch release cylinder installed in the engine compartment on the front end shield;

- - working cylinder located on the gearbox housing;

- - a pipeline consisting of a tube and an intermediate hose connecting the main cylinder to the working cylinder;

- - clutch pedal, the bracket of which is attached to the body. The pedal returns to its original position by a spring

The master cylinder is connected by a hose to a reservoir mounted on the brake master cylinder (the reservoir is common to both master cylinders).

The hydraulic clutch release uses brake fluid. Adjustment of the clutch release actuator in operation is provided.

Technical data

Clutch drive - Hydraulic

Diameter of friction linings (external x internal), mm 225x150 (2.5 l); 215x145 (2.0 l)

Installation load of the clutch cover, N 4500–4900 (2.0 l); 5400-5800 (2.5L)

Internal diameter of the main cylinder, mm 20.64

Internal diameter of the working cylinder, mm 15.87

Adjustment data

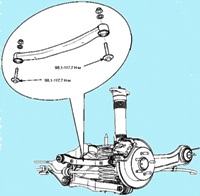

Clutch disc thickness, mm 8.3 -8.9 (2.5 l); 8.2 -8.8 (2.0 l)

Clutch pedal installation height, mm 180.5±0.3

Clutch pedal free travel, mm 6–13

Clutch pedal travel, mm 150

Minimum allowable distance to the rivet heads at the limit wear of the friction linings of the clutch disc, mm 0.3

The difference in the height of the ends of the diaphragm spring, mm 0.5

Gap between piston and clutch slave cylinder, mm 0.15

Gap between piston and clutch master cylinder, mm 0.15

Recommended lubricants

Elements - Grease

Contact surface of the clutch release bearing and the clutch release fork support - CASMOLY L 9508

Clutch release bearing inner surface - CASMOLY L 9508

Clutch Release Cylinder Inner Surface, Piston and Cuffs - DOT 3 Brake Fluid

Clutch splines - CASMOLY L 9508

Clutch Master Cylinder Inner Surface, Piston and Cuffs - Brake Fluid DOT 3

Clutch Master Cylinder Pusher, Cap Pin & Cotter Pin & Washer - SAE J310a, NLGI #2

Clutch pedal shaft and bushings - SAE J310a, NLGI #1

Clutch release fork - CASMOLY L 9508

Gearbox input splines - CASMOLY L 9508

Tightening torques, Nm

Clutch pedal bracket 25-35

Clutch master cylinder bolt 8–12

Clutch pipe connecting nuts 12–16

Clutch Release Cylinder Bolt 15-22

Clutch Release Cylinder Connection Bolt 25

Clutch cover (2.0L) 15-22

Clutch cover (2.5L) 20-27

Clutch master cylinder tappet locknut 10–15

Clutch master cylinder reservoir 8-10

Ignition interlock switch 8–10

Bleeding the clutch hydraulic system

During bleeding, add only clean fluid recommended by the manufacturer.

Do not mix brake fluids of different brands.

Brake fluid: SAE J1703 (DOT 3)

The fluid used in the hydraulic drive dissolves paint and plastic, so if the fluid gets on the paintwork of the car, wash it plenty of water.

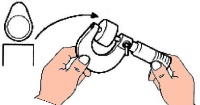

Loosen the bleed screw on the clutch release cylinder and attach a hose to it.

Place the other end of the hose in a glass container of sufficient volume.

Slowly depress the clutch pedal.

With the clutch pedal depressed, loosen the bleeder valve and bleed the air from the hydraulic system.

Tighten the bleed screw and release the clutch pedal.

Repeat the operations until the brake fluid comes out without air bubbles.

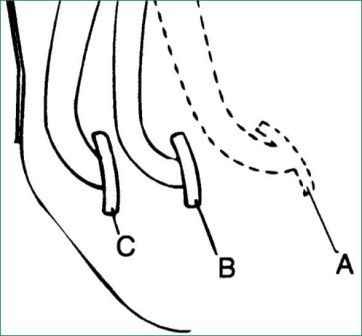

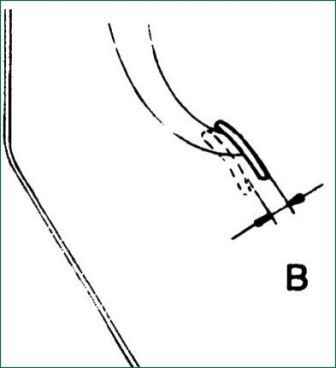

Fast repeated depressing of the clutch pedal in area (B - C) may cause the pushrod to come out of the clutch cylinder body during bleeding.

It is only necessary to press the clutch pedal after it has returned to its upper position (A).

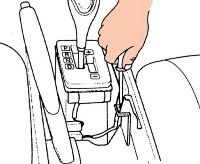

Clutch pedal adjustment

Measure from the front of the pedal to the carpet.

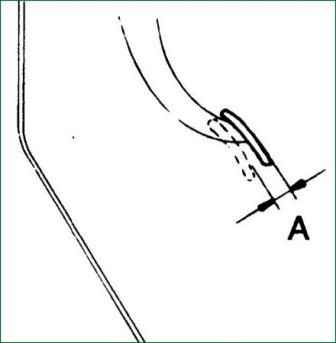

Press the clutch pedal by hand until you feel resistance and measure the amount of free play.

Clutch pedal free travel (A): 1-3 mm

If the clutch pedal free play is not the correct value, adjust it.

Loosen the locknut and turn the bolt to adjust the clutch pedal free play, then tighten the locknut.

After adjusting, tighten the bolt until it reaches the pedal stop, then tighten the locknut.

Turn the plunger until the desired free play is reached, then tighten the locknut.

When adjusting the mounting height or clutch pedal free play, be careful not to move the pushrod to the clutch master cylinder.

After completing the adjustments, check that the distance from the clutch pedal to the floor with the pedal pressed corresponds to the required value.

Clutch pedal free travel (B): 6-13 mm

If you cannot adjust the installation height and clutch pedal free play, there may be air in the clutch hydraulic system or the clutch master cylinder is faulty.

In this case, bleed or disassemble and check the clutch master cylinder.

Clutch Troubleshooting

Fault

- Probable cause

Remedy

Clutch slip (Vehicle does not accelerate when engine speed is increased; insufficient vehicle speed; insufficient power on hills)

- Insufficient clutch pedal clearance

Adjust clutch pedal clearance

- Clogged hydraulic clutch

Clean or replace parts

- Excessive clutch disc wear

Replace clutch disc

- Jamming of the disc on the splines of the input shaft or oil on the friction linings

Replace clutch disc

- Damaged pressure plate or flywheel

Replace pressure plate or flywheel

- Weak or broken diaphragm spring

Replace pressure plate

Difficulty shifting gears (gear noise when shifting gears)

- Excessive clutch pedal clearance

Adjust clutch pedal clearance

- Clutch fluid leak

Locate the leak and fix it

- Wear or corrosion of the clutch disc

Replace clutch disc

- Excessive clutch disc distortion

Replace clutch disc

Clutch noise (When clutch is not in use)

- Insufficient clutch pedal gap

Adjust clutch pedal clearance

- Excessive clutch disc wear

Replace clutch disc

Noise after clutch disengagement

- Wear or damage to the clutch release bearing

Replace the clutch release bearing

Noise when disengaging the clutch

- Lack of lubrication on the surface of the support sleeve

Lubricate the surface of the support sleeve

- Improperly installed clutch release bearing

Repair

The appearance of noise when driving a car with a partially engaged clutch

- Damaged guide sleeve

Replace guide bushing

Clutch pedal hard to press

- - Insufficient clutch pedal lubrication

- - Not enough lubricant on the splines of the clutch disc

- - Not enough grease on the clutch release shaft lever

- - Not enough grease on the front cover of the bearing assembly

Repair

Gears turn on with difficulty or not turn on at all

- Insufficient clutch pedal clearance

Adjust clutch pedal clearance

- Faulty clutch release cylinder

Repair or replace

- Excessive clutch disc runout

Repair or replace

- Gearbox input shaft splines are dirty or rusty

Repair

- Faulty clutch pressure plate

Replace clutch pressure plate

Clutch slip

- Insufficient clutch pedal clearance

Adjust clutch pedal clearance

- Clogged hydraulic clutch

Clean or replace parts

- Clutch disc wear

Replace clutch disc

- Faulty clutch pressure plate

Replace clutch pressure plate

- The fastening of the clutch release fork is broken

Repair

Clutch vibration

- The clutch disc is deformed, worn or has oil on it

Check the clutch disc

- Faulty clutch pressure plate

Replace clutch pressure plate

- Damaged or broken diaphragm spring

Replace pressure plate

- Damaged clutch disc damping spring

Replace clutch disc

- Loose fastening of the sub-frame

Repair

Clutch noise

- Damaged clutch pedal sleeve

Replace clutch pedal bushing

- The fastening in the clutch cover is loose

Repair

- Worn or dirty clutch release bearing

Replace the clutch release bearing

- The fastening of the clutch release fork is broken

Repair