During operation, as well as due to an error in the manufacture of parts of the gas distribution mechanism drive (GRM) or due to unskilled repair of the timing drive, a significant deviation of the valve timing from the specified values is possible

The correct valve timing is one of the most important factors affecting the power, torque and economic performance of the engine.

Therefore, with a decrease in the traction properties of the engine, an increase in operating fuel consumption and unstable engine operation, it becomes necessary to check and, if necessary, correctly set the valve timing.

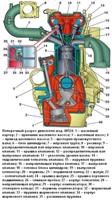

For this purpose, a tooling kit developed at ZMZ is used. Includes: Protractor (Figure 1)

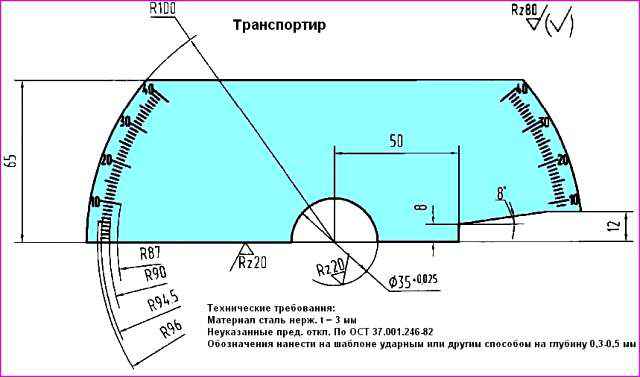

- - template (Figure 2) with cam profile and arrow

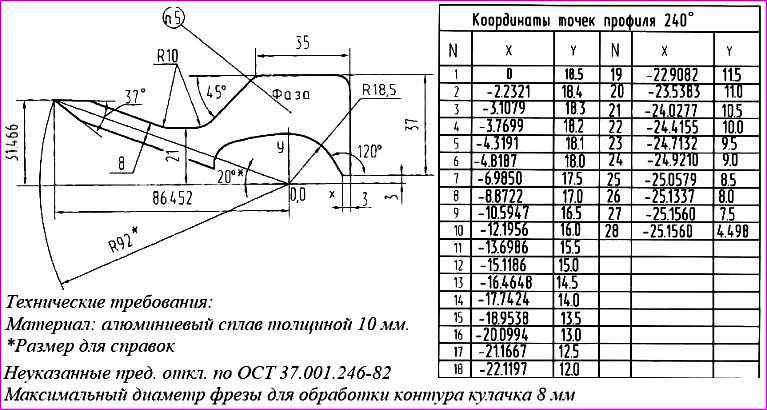

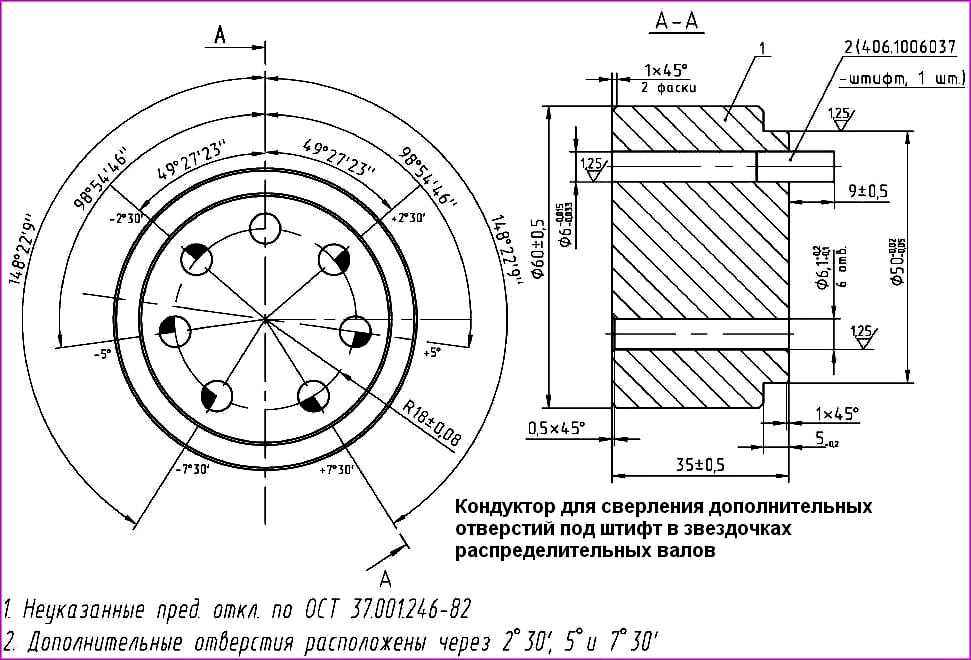

- - and a jig for drilling additional pin holes in the camshaft sprockets (Figure 3)

Checking and adjusting the valve timing can be carried out on an engine installed on a car; to control the valve timing, you must:

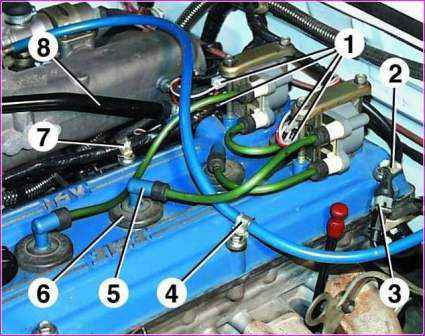

Disconnect the crankcase ventilation hose from the valve cover fitting by loosening the clamp.

Disconnect wire connectors from ignition coils.

Remove the tips from the spark plugs with seals and high voltage wires.

Release from the brackets and move the wiring harness away from the valve cover.

Remove the valve cover with gasket, spark plug seals, ignition coils and high-voltage wire assembly by unscrewing eight bolts (head "12", extension and knob).

Leave the bolts, washers and wire harness clips in the cover holes. (Picture 4 shows the steps on the example of ZMZ-4062)

Set the piston of the 1st cylinder to the TDC of the compression stroke by turning the crankshaft in the direction of rotation (clockwise) until the mark on the crankshaft damper pulley coincides with the pointer rib (in the form of a tide) on the chain cover.

Attention! Counterclockwise rotation of the crankshaft is not allowed.

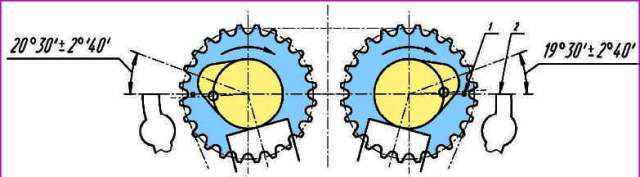

In this case, the camshaft cams of the 1st cylinder and the marks on the camshaft sprockets should be located according to the diagram (Figure 5).

If the tops of the cams and marks are located inside, then it is necessary to turn the crankshaft one more turn.

The exact setting of the piston of the 1st cylinder at TDC can be carried out using a dial indicator, which is installed and fixed in the spark plug hole of the 1st cylinder.

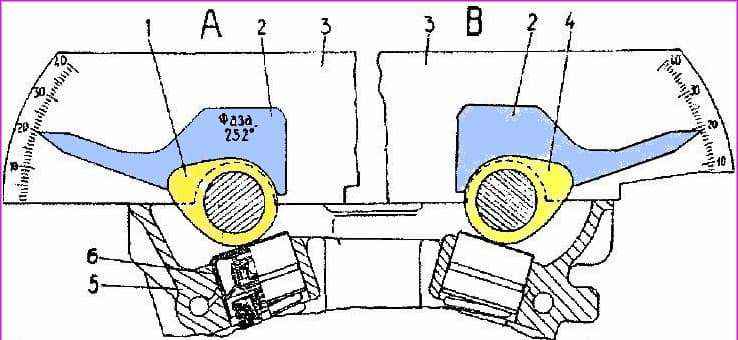

Install protractor 3 (Figure 6) behind the first cam spread intake valve shaft - view "A", placing it between the cam and the cover of the camshaft support.

Pressing the protractor 3 against the upper plane of the cylinder head 5, attach and firmly press the template 2 to the surface of the first cam.

In this case, the arrow of the template should be located on the protractor mark 20˚30′± 2˚40′

When measuring, the leading branch of the chain in the region of the upper damper (between the sprockets of the camshafts) must be tensioned and held in this state by turning the intake camshaft counterclockwise with a key to "27" by the square on the shaft body.

In this case, turning the exhaust camshaft is not allowed.

Similarly, check the angular position of the first cam of the exhaust camshaft - view "B".

The template arrow should point to the protractor mark 19°30′±2°40′.

When measuring, the drive branch of the chain in the area of the middle damper (between the camshaft sprocket and the intermediate shaft drive sprocket) must be tensioned and held in this state by turning the exhaust camshaft counterclockwise with a “27” wrench on the square on the shaft body.

In this case, turning the intermediate and crankshafts is not allowed.

With these values of the angular position of the first cams of the camshafts, the best technical and economic indicators of the engine are achieved.

If the deviations of the angular position of the camshaft cams exceed the allowable ± 2 ° 40 ′, adjustment of the valve timing is required.

To do this, the following work must be done on the engine:

- 1. Remove the front cover of the cylinder head by unscrewing the four bolts (wrench "12").

- 2. Remove the upper hydraulic tensioner (in the cylinder head) by unscrewing the two bolts (head "12", extension and knob) securing the hydraulic tensioner cover, remove the cover with a soundproof washer.

- 3. Remove the upper and middle chain guides by unscrewing their fastening bolts two each (wrench “6” for bolts with a hexagon socket).

- 4. Remove the camshaft sprockets by unscrewing their fastening bolts one by one (key "12"), while holding the shafts with the key "27" by the square on the body of the camshaft.

Keep the chain removed from the camshaft sprockets from jumping off the intermediate shaft sprocket.

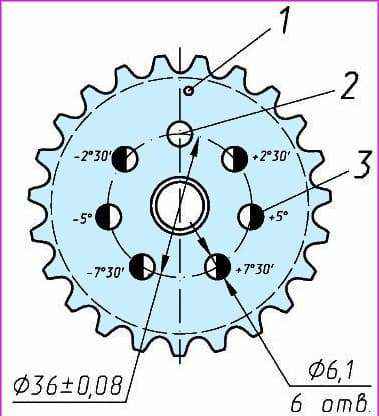

- According to the jig installed on the sprocket, in each sprocket, drill six additional holes 3 (Figure 7) Ø 6.1 mm with angular displacements of 2°30', 5°00' and 7°30' from the nominal position of the factory hole 2 located along the symmetry axis of one of the tooth troughs of the sprocket.

At the same time, three additional holes, displaced from the axis of symmetry of the cavity of the teeth clockwise, are positive, three others, displaced counterclockwise, are negative, if you look at the sprocket from the side of mark 1.

If, when adjusting the valve timing, it is required to rotate the camshaft (shafts) in the direction of its (their) rotation (clockwise), then the asterisk (sprockets) must be installed on one of the additional holes with a positive offset, located to the right of the factory hole, if - counterclockwise, then install the asterisk (asterisks) on one of the holes with a minus offset, located to the left of the factory hole.

The choice of the hole on the sprocket, with the required amount of displacement, is made depending on the amount of deviation of the angular position of the cam from the nominal value.

When installing a sprocket on an additional hole, the factory alignment mark 1 on the sprocket will not coincide with the top plane of the cylinder head

Example

As an example, consider adjusting the valve timing when the template needle reads 23°30′ for the intake cam and 16°30′ for the exhaust cam, these angles exceed the nominal values for the intake and exhaust cams by 3°, which is more than the tolerance of ± 2°40′.

With these indications of the angular position of the cams and, given that the camshafts rotate clockwise when the engine is running, observing from the side of the crankshaft pulley, the start of opening of the intake and exhaust valves will occur with some advance from the factory values of the gas distribution phases.

To adjust the phases, in this case, it is necessary to turn the camshafts counterclockwise and use an additional hole when installing sprockets 2°30′ minus angular offset pin (first hole to the left of the factory hole).

Next, continue the work in the following sequence:

- 1. Turn with a 27 mm wrench and install the exhaust camshaft so that the template arrow is opposite the protractor mark 19°30’.

- 2. Throw the chain over the sprocket and orient its first additional hole, located to the left of the factory hole, so that it is in front of the camshaft pin, and the chain drive branch (near the middle damper) is tensioned.

To install the sprocket on the flange and camshaft pin, turn the camshaft slightly clockwise with a wrench.

After installing the sprocket, turn the camshaft counterclockwise to tighten the drive branch of the chain, while the arrow of the template mounted on the cam should show 19°30′±2°40′.

- 3. Position the intake camshaft so that the arrow on the template is opposite the protractor mark 20°30’.

- 4. Install the sprocket onto the intake camshaft in the same way as the exhaust camshaft sprocket using the same extra hole.

- In this case, with the leading branch of the chain stretched (in the area of the upper damper), the arrow of the template installed on the cam should show 20˚30′±2˚40′.

- 5. Pre-tighten the sprocket mounting bolts (wrench “12”).

- 6. Disassemble and assemble ("charge") the hydraulic tensioner, install it in the hole in the cylinder head, close the cover by tightening the cover bolts, and unscrew the plug from the cover.

- 7. Through the hole in the cover of the hydraulic tensioner with a metal rod or a screwdriver, press the hydraulic tensioner, moving it until it stops, then release it - the hydraulic tensioner will be “discharged” when the retaining ring on the plunger disengages from the hydraulic tensioner body and allows the plunger and the body to move under the action of the spring.

The body will move all the way into the cover, and the chain will be tensioned through the tensioner lever.

- 8. Screw the plug into the cover of the hydraulic tensioner, having previously applied the “Stop - 6” sealant to the thread of the plug.

- 9. Check the correct installation of the valve timing by turning the crankshaft in the direction of rotation two turns and aligning the marks on the damper pulley and the chain cover.

Check with a protractor and cam template as described above.

The arrow of the template installed on the intake cam should show 20°30′±2°40′, and on the exhaust cam 19°30′±2°40’.

If this condition is not met, it is necessary to repeat the installation of the valve timing.

- 10. Screw in and tighten the camshaft sprocket bolts to a final torque of 56-62 Nm (5.6 - 6.2 kgcm).

- 11. Install the upper and middle chain guides by screwing and tightening the fastening screws to a torque of 20-25 Nm (2.0 - 2.5 kgcm) (key “6” for bolts with a turnkey hexagon socket, torque wrench with head “6”).

Preliminarily apply "Stop-6" sealant to the screws securing the dampers.

- 12. Reassemble the engine in the reverse order of disassembly

After adjusting the valve timing, the engine should run like clockwork.