- Replacing the hydraulic chain tensioner VAZ-2123

- Adjusting the thermal clearances of the valves of the VAZ-21114 engine

- How to remove the exhaust pipes and exhaust manifold of the ZMZ-406 engine

- ZMZ-409 engine hydraulic compensator

- Checking the knock sensor ZMZ-406

- Engine management system VAZ-21114

- How to check and replace the timing belt of the VAZ-21114 engine

- Replacing the oil pump of the VAZ-21126 engine

- Repair of generators G250P2, 665.3701-01 and 161.3771

- Replacing the cylinder head cover gasket VAZ-21126

- Disassembly of the VAZ-21126 engine

- Maintenance of diesel D-245

- Disassembly and assembly of the VAZ-21114 engine

- Assembly of the VAZ-21126 engine

- Removing the radiator and pressure reducing valve of the oil system ZMZ-409

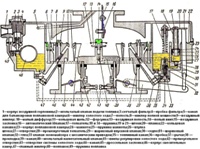

- Scheme and elements of the K-151 carburetor

- Removal and installation of the K-151 carburetor

- Replacing the chain tensioner shoe VAZ-2123

- Features of the carburetor 21083–1107010-31

- Diesel nozzle D-245

- Replacing the K-151 carburetor

- Features of the ZMZ-409 lubrication system

- How to replace the hydraulic compensators of the VAZ-21126 engine

- How to check and replace the hydraulic pusher of the valve actuator ZMZ-405, ZMZ-406

- How to repair the cylinder head of the ZMZ-405, ZMZ-406 engine

- Requirements for the gas distribution mechanism D-245

- Replacing the timing belt of the VAZ-21126 engine

- The design of the oil pump of the ZMZ-402 engine

- Laying the crankshaft diesel D-245

- Cylinder head D-245.12

- Disassembly and assembly of the carburetor-21083

- Replacing the cylinder head gasket of the VAZ-21126 engine

- Centrifugal oil filter D-245

- How to replace hydraulic lifters VAZ-2123

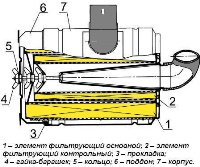

- Diesel oil filter D-245

- How to remove and install the flywheel of the ZMZ-406 engine

- Features of the D-245.12 diesel engine

- Requirements for parts of the crank mechanism D-245.12

- Installation of gas distribution phases VAZ-2123

- Replacing the crankshaft ZMZ-406

- Troubleshooting engine parts VAZ-21126

- How to replace the cylinder head gasket VAZ-2123

- Removal, installation and repair of the crankshaft ZMZ-409

- Technical characteristics of the pump TNVD - 4UTNI-T-1111005-50 diesel D-245

- Generator G250P2 and generators 665.3701-01 and 161.3771

- Dismantling diesel D-245

- Replacing the cylinder head gasket ZMZ-409

- Repair of the water pump ZMZ-409

- Engine design VAZ-21126

- Features of the carburetor DAAZ 2107