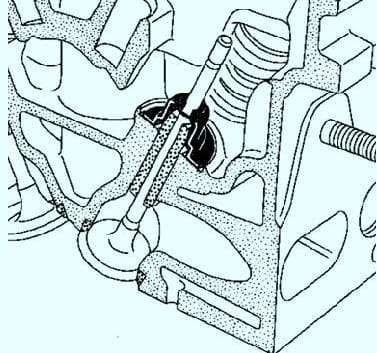

Removing valve springs

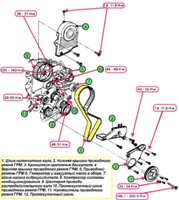

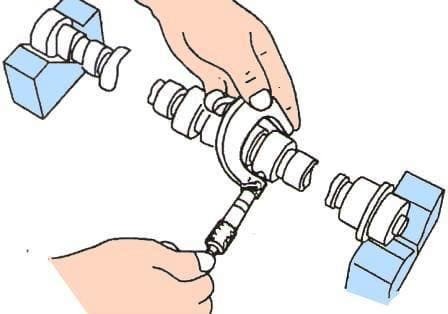

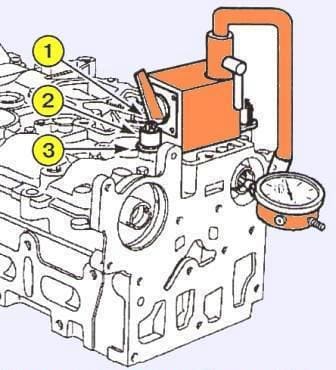

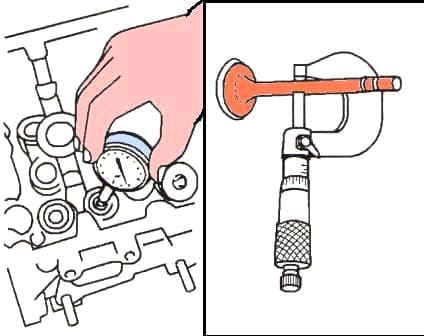

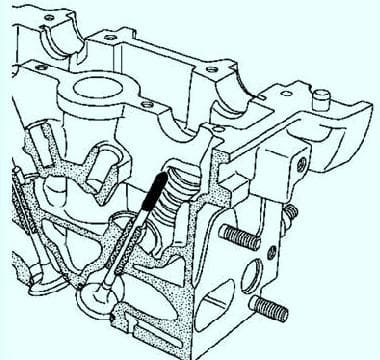

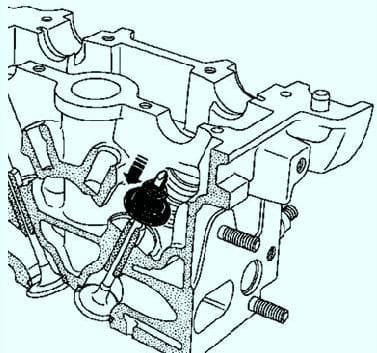

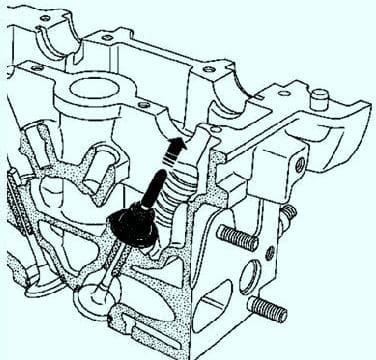

To properly compress the valve springs, the tool plug (Mot. 1502) must be centered on the valve stem

The valve spring plate must fit into the bore of the pressure sleeve of tool (Mot. 1502) (fig. 1).

Remove:

- - crackers;

- - valve spring plates;

- - valve springs;

- - valves;

- - slinger caps with pliers (Mot. 1335).

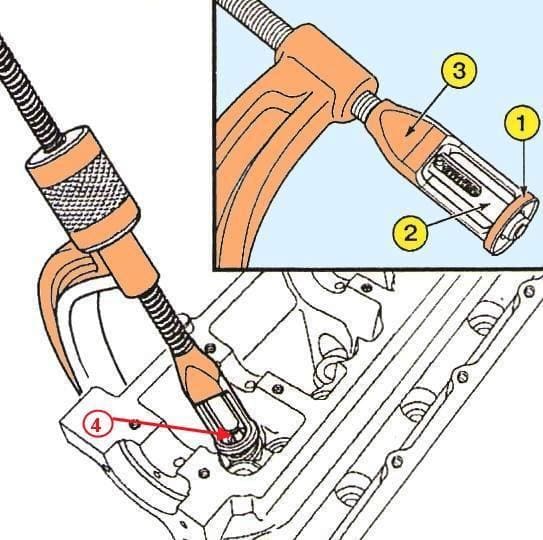

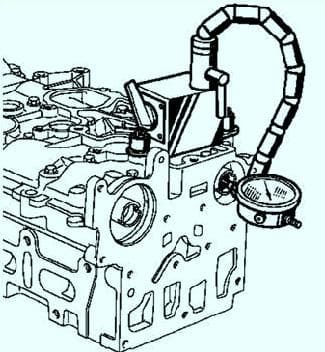

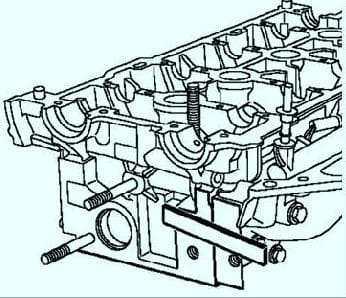

Checking the cylinder head height

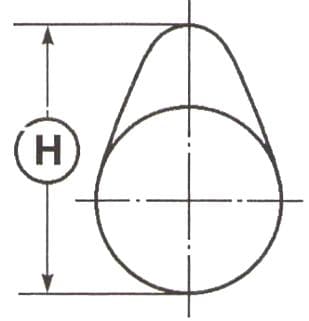

Measure the height of the cylinder head (fig. 2).

Height of the cylinder head is 137 mm.

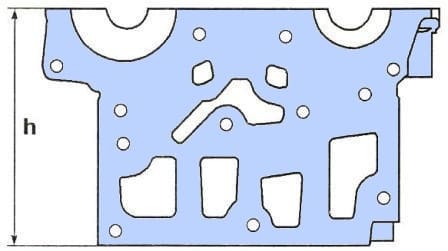

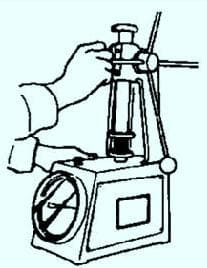

Checking the tightness of the cylinder head

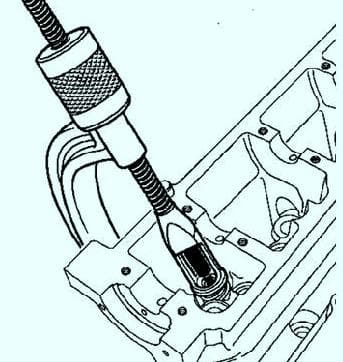

Check the cylinder head for cracks using a special tool (fig. 3).

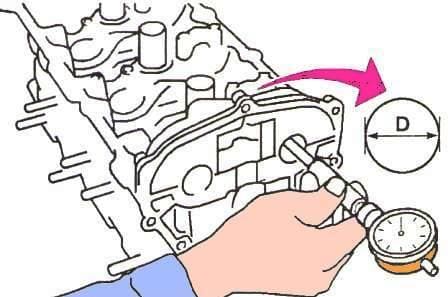

Measure the height of the cams (fig. 4).

Cam height:

- - inlet: 40.661 ± 0.03 mm;

- - exhaust: 40.038 ± 0.03 mm.

Checking the diameters of the bearing journals and the bores of the camshaft bearings

Measure the diameter of the prop camshafts (fig. 5).

Camshaft journal diameter:

- - necks No. 1,2, 3, 4, 5 - 24.979–25.000 mm;

- - neck #6 - 27.979-28.000 mm.

Measure the diameter of each hole in the camshaft bearings (fig. 6).

Camshaft bearing bore diameter:

- - necks No. 1,2, 3, 4, 5 - 25.040–25.061 mm;

- - neck #6 - 28.040-28.061 mm.

Checking the axial movement of the camshafts

Install the camshafts, making sure they are in the correct position, and the cylinder head cover.

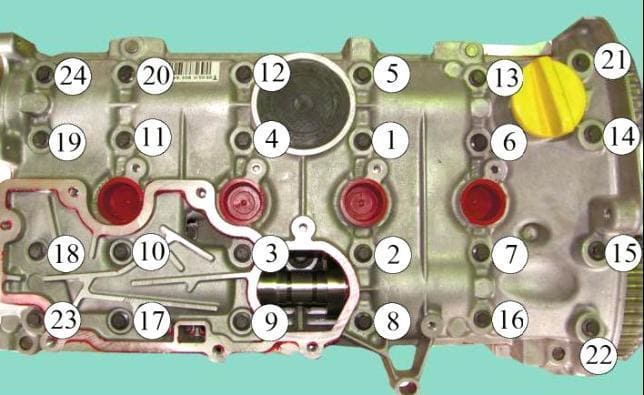

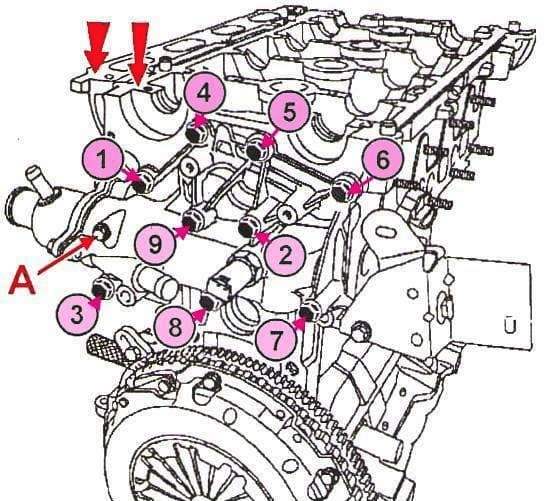

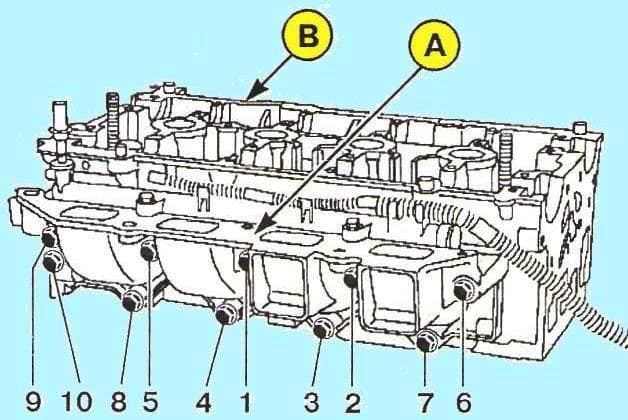

Tighten in the order shown in Figure 7 to the correct torque:

- - cylinder head bolts 13-20-22-23 (8 Nm),

- - cylinder head cover bolts from 1-12, from 14-19 and 21-24 (15 Nm).

Loosen the cylinder head cover bolts 13–20–22–23.

Tighten the cylinder head cover bolts 13-20-22-23 (15 Nm) in the order shown.

Fix the magnetic strut to the cylinder head using the fixing plate of the tool (Mot. 588), tightening it with the oil separator mounting bolts and spacers having the following dimensions:

- – outer diameter 18 mm,

Fig. 8. Installation of the magnetic rack on the cylinder head:

- 1 - mounting plate;

- 2 - spacers;

- 3 - bolts

- – bolt hole diameter 89 mm,

- - height 15 mm (Fig. 8).

Check the axial movement, which should be between 0.08 - 0.178 mm (Fig. 9)

Remove the cylinder head cover and camshafts.

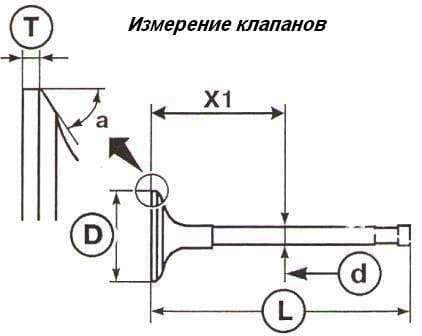

Checking valves

The diameter D of the valve stem is measured at distance X1.

- Inlet valves: Х1=75.14±0.35mm, D=5.470-5.485mm.

- Exhaust valves: X1=77.5±0.35mm, D=5.456-5.471mm.

Valve head diameter D:

- - inlet valves - 32.7 ± 0.12 mm;

- - exhaust valves - 27.96 ± 0.12 mm

Flap length L:

- - inlet valves - 109.32 mm;

- - exhaust valves - 107.64 mm

Chamfer angle A:

- -inlet - 45°45’

- - exhaust valves - 45°

Head thickness T:

- - intake valves - 1.15 mm;

- - exhaust valves - 1.27 mm

Valve travel:

- - intake valves - 9.221 mm;

- - exhaust valves - 8.075 mm

Checking clearance between valve stems and valve guides

There are two ways to check the clearance between the valve stem and the valve guide.

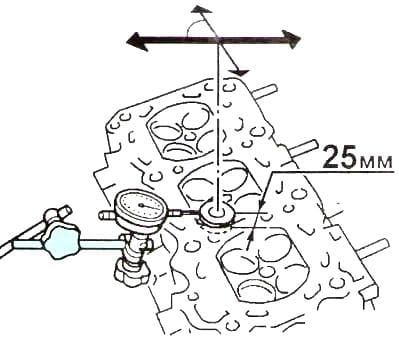

First way

Raise the valve head by 25 mm, then measure the movement of the valve in the direction of the arrows at an angle of 90 ° to the camshaft axis with the indicator.

Half of the resulting value is equal to the gap between the valve stem and the valve guide (Fig. 11).

Second method

Measure the valve stem diameter and the inner diameter of the guide sleeve.

The gap between the valve guide and the valve stem is calculated by subtracting the values of the two measured diameters (fig. 12).

Nominal clearance:

- - for inlet valves - 0.015–0.048 mm;

- - for exhaust valves - 0.029-0.062 mm.

Check valve springs

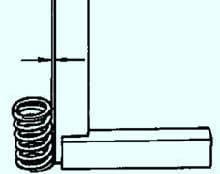

Check the deflection of the spring from the vertical, which should not exceed 1.2 mm (Fig. 13).

Check the calibration of the springs.

Spring length under load:

- - under a load of 18–20 N, the length of the spring is 34.50 mm;

- - under a load of 56.3–61.7 N, the length of the spring is 24.50 mm;

- – free length of the spring 41.30 mm (Fig. 14).

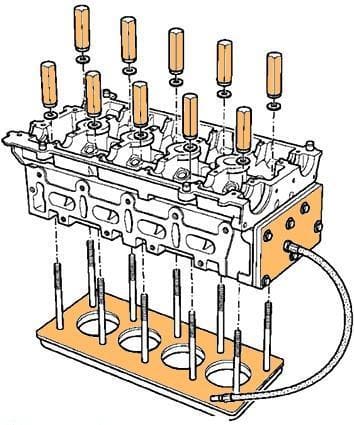

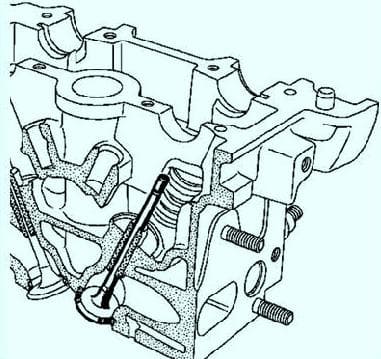

Cylinder head assembly

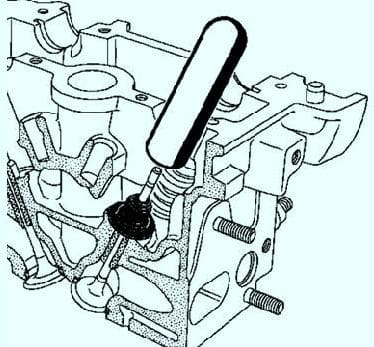

Insert the valve into the cylinder head (fig. 15).

Place the tip of the tool (Mot. 1511) on the valve stem (the inner diameter of the tip must be equal to the diameter of the stem).

Keep the valve pressed against the seat (fig. 16).

Install the flinger cap (lubricated with oil) on the tip.

Slide the slinger cap until it passes over the tip (fig. 17).

Remove the tip (fig. 18).

Install the mandrel on the oil seal (Fig. 19).

The inner diameter of the mandrel must match the diameter of the valve stem.

In addition, the bottom of the mandrel should partially abut against the valve stem seal, which serves as the valve spring washer.

Press on the slinger cap by tapping the top of the mandrel with your palm until the slinger cap contacts the cylinder head (fig. 20).

Repeat for all valves.

Install the springs and spring plates (fig. 21).

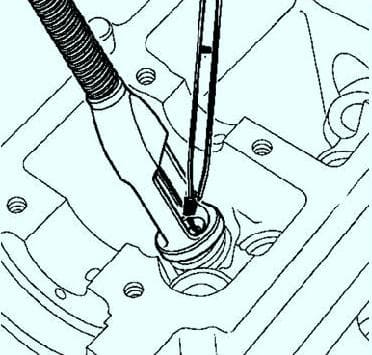

Insert the breadcrumbs using curved tongs (fig. 22).

Install the thermostat unit with a new gasket on the cylinder head.

In the order shown in figure 23, to the required torque (10 Nm), tighten the bolts securing the thermostat unit to the cylinder head.

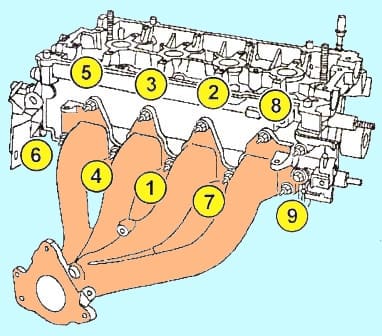

Install the exhaust manifold with a new gasket.

In the order shown in figure 24, tighten the exhaust manifold stud nuts to the required torque (23 Nm)

Install the exhaust manifold heat shield.

Torque tighten the exhaust manifold heat shield mounting bolts.

Make sure the exhaust manifold heat shield is securely fixed between the oxygen sensor and the manifold (to avoid overheating which could destroy the upstream oxygen sensor wiring).

Torque tighten (4.5 Nm) the oxygen sensor using tool (Mot. 1495).

Install the inner timing case spacer.

Install the injector body shims with a new gasket. Install the oxygen sensor.

Align the lining of the injector bodies with respect to the cylinder head (on the timing side) (Fig. 25).

Align the mating planes of the lining of the injector bodies with respect to the cylinder head.

Tighten the bolts securing the gasket of the injector bodies (Fig. 26) in the specified order to a torque (21Nm).