The clutch is located between the engine and the gearbox and is designed to disconnect and connect the flywheel mounted on the engine crankshaft and the gearbox input shaft

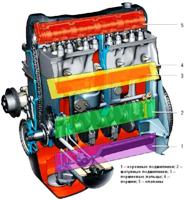

On vehicles equipped with a manual transmission, a diaphragm-type dry single-plate clutch is used (Fig. 1).

The clutch consists of a driven (friction) disc (Fig. 2)

Clutch cover (fig. 3)

Pressure plate (fig. 4)

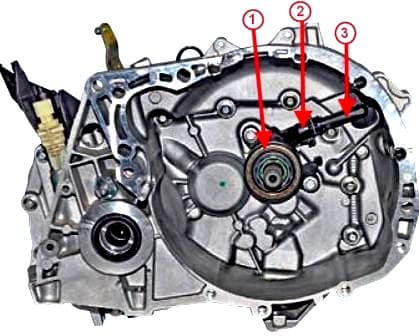

The release bearing 1 (Fig. 3) is of closed type, mounted on the guide sleeve of the clutch slave cylinder.

The bearing is moved by the working cylinder 2 mounted on the input shaft of the gearbox.

Before carrying out any operation on the clutch, it is necessary to carry out several checks to make sure that the clutch is not working.

First of all, check the fluid level in the tank, then the condition of the hoses and their connections.

Inspect the clutch pedal bushings for wear and tightness

Bleeding the hydraulic clutch release

Be careful not to spill clutch fluid on painted surfaces. If this happens, immediately wash off the liquid with water.

Do not mix different brands of clutch fluids.

Do not reuse drained clutch fluid.

Any hydraulic system works fine when it is bled of air.

When pumping, add only clean fluid recommended by the manufacturer.

Never reuse fluid leaked from the hydraulic clutch release.

If fluids of different brands are accidentally mixed in the hydraulic system, remove the fluid from it, flush it with a clean fluid of the required brand and install new o-rings.

In case of constant fluid leakage from the hydraulic drive or air entering it, determine the cause and location of the leak, and repair the damage.

Poorly performed hydraulic drive bleeding can cause incorrect diagnostic results and unjustified replacement of parts.

For any work on the hydraulic clutch, be sure to bleed the parts of the hydraulic circuit:

- – between the tank and the air outlet;

- - between the bleed valve and the clutch slave cylinder;

- - with increased pedal free play.

Put the car on a two-post lift.

Remove the engine undertray.

Disconnect the connector of the brake fluid level sensor in the reservoir.

Remove the brake reservoir cap.

Bleeding air from the circuit between the tank and the bleed valve

Install and lock the clutch pedal in the up position.

Fill the reservoir with approved brake fluid.

Remove the plug from the bleed valve.

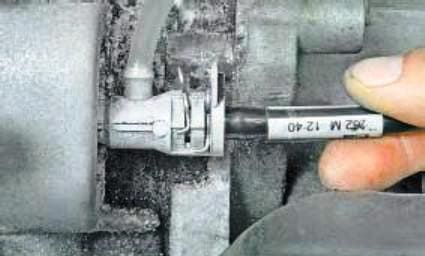

Put a transparent tube (fig. 3) over the clutch slave cylinder bleeder, lowering its end into an empty container installed below the bleeder.

Ask an assistant to slowly depress the clutch pedal 10 - 15 times with an interval of 2 - 3 seconds. and release the pedal

Press the lock (Fig. 4).

Do not pull on the latch.

In case of any erroneous action, the pipeline must be replaced.

Open the bleed valve by pulling out the hydraulic clutch line one click.

Have an assistant depress the clutch pedal and keep it depressed.

Liquid with air bubbles will flow from the hose into the container.

As soon as the liquid stops flowing out, slide the hose tip into the working cylinder nozzle and fix it with a spring retainer.

Release the clutch pedal and wait a few seconds.

Wait until there are no air bubbles in the brake fluid flowing into the container.

Make sure that the fluid level in the reservoir of the main brake cylinder does not fall below normal during bleeding.

Fixation of the hydraulic clutch pipeline should be accompanied by a characteristic click.

Clutch off and on about ten times.

Pour liquid into the tank up to the maximum level mark.

Check clutch operation. Repeat the operation if necessary.

Clutch pedal freeplay adjustment

Disconnect the supply line between the reservoir and the clutch master cylinder.

Close the opening of the tank.

Add a small amount of certified brake fluid to the syringe.

Insert the syringe into the supply line between the reservoir and the clutch master cylinder.

Purge the air from the clutch master cylinder with a syringe.

Remove the syringe.

Connect the clutch master cylinder supply line to the reservoir.

Depress the clutch pedal five times.

Add fluid to the tank up to the maximum level mark.

Check clutch operation.

Repeat the operation if necessary.

Install the cap on the brake reservoir.

Connect the connector of the brake fluid level sensor in the reservoir.

Install the engine undertray.